What Is a DC Solenoid?

A DC Solenoid is an electrical component that converts the electrical energy of electromagnetic force applied to a coil into mechanical energy for linear drive by a moving iron core.

Its function as an actuator is realized by a component that combines a coil with a movable iron core. A typical solenoid is based on a pull-type motion to retract the movable iron core.

By combining various movable iron core tip shapes and driving parts, movements such as “pull, push, stop, strike, and bend” can be achieved at low cost. Therefore, DC solenoids are used not only in industrial machinery applications such as home appliances, ATMs, vending machines, ticket checkers, and automatic doors, but also in various applications in our daily lives.

Applications of DC Solenoid

DC Solenoid is used in a wide variety of applications for machines and devices around our daily life because of its controllability and responsiveness, as well as its movable iron core and tip shape, which enable various movements such as pulling, pushing, stopping, hitting, and bending at low cost.

Major applications include coin sorting machines in vending machines, automatic doors and ticket gates on train platforms, locking mechanisms in parking lots and automatic doors, control devices in ATMs, and delivery boxes installed in condominiums and convenience stores.

Principle of DC Solenoid

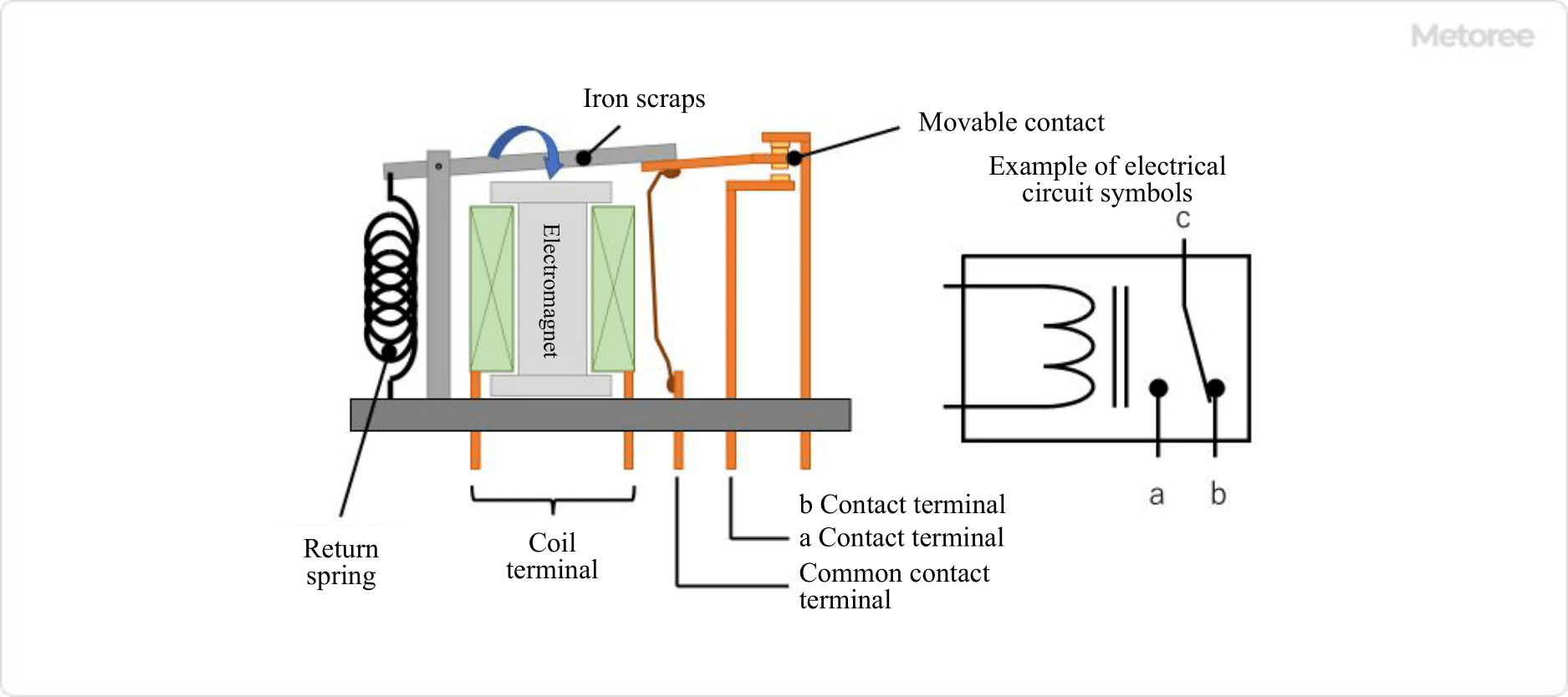

The principle of DC Solenoid is based on Faraday’s law of electromagnetic induction. The electrical energy of electromagnetic force flowing through a coil is converted into mechanical energy for linear drive by a movable iron core.

Compared to AC solenoids, DC solenoids do not generate inrush current when energized and are quieter than AC solenoids. Normally, a DC solenoid consists of the following components: a main frame, a coil, a spring, a fixed iron core, and a movable iron core.

When current flows through the coil, a magnetic field is generated at the same time, and the movable iron core is attracted to the fixed iron core by electromagnetic induction, enabling pull-type operation. While the coil is energized, the movable iron core is attracted to the fixed iron core, and when the coil is de-energized, the movable iron core returns due to spring force.

On the other hand, there is a push type that has a push bar on the fixed iron core to push out the push bar as soon as the movable iron core is attracted to the fixed iron core. By changing these tip shapes, various operations can be realized at low cost.

Other Information on DC Solenoid

1. Difference Between AC Solenoid and DC Solenoid

AC solenoids feature higher starting current and pull force than DC solenoids. However, if an AC solenoid is overloaded and locked during movement, a large current will continue to flow, resulting in coil burnout. Therefore, when adopting AC solenoids, it is important to design them with safety considerations such as thermal fuses and overcurrent protection.

On the other hand, DC Solenoid has a small current and low pull force, so even if a moving part is overloaded or locked, the coil will not be burned out, Therefore, it is necessary to select the right solenoid depending on the operating conditions.

2. Self-Holding Solenoid

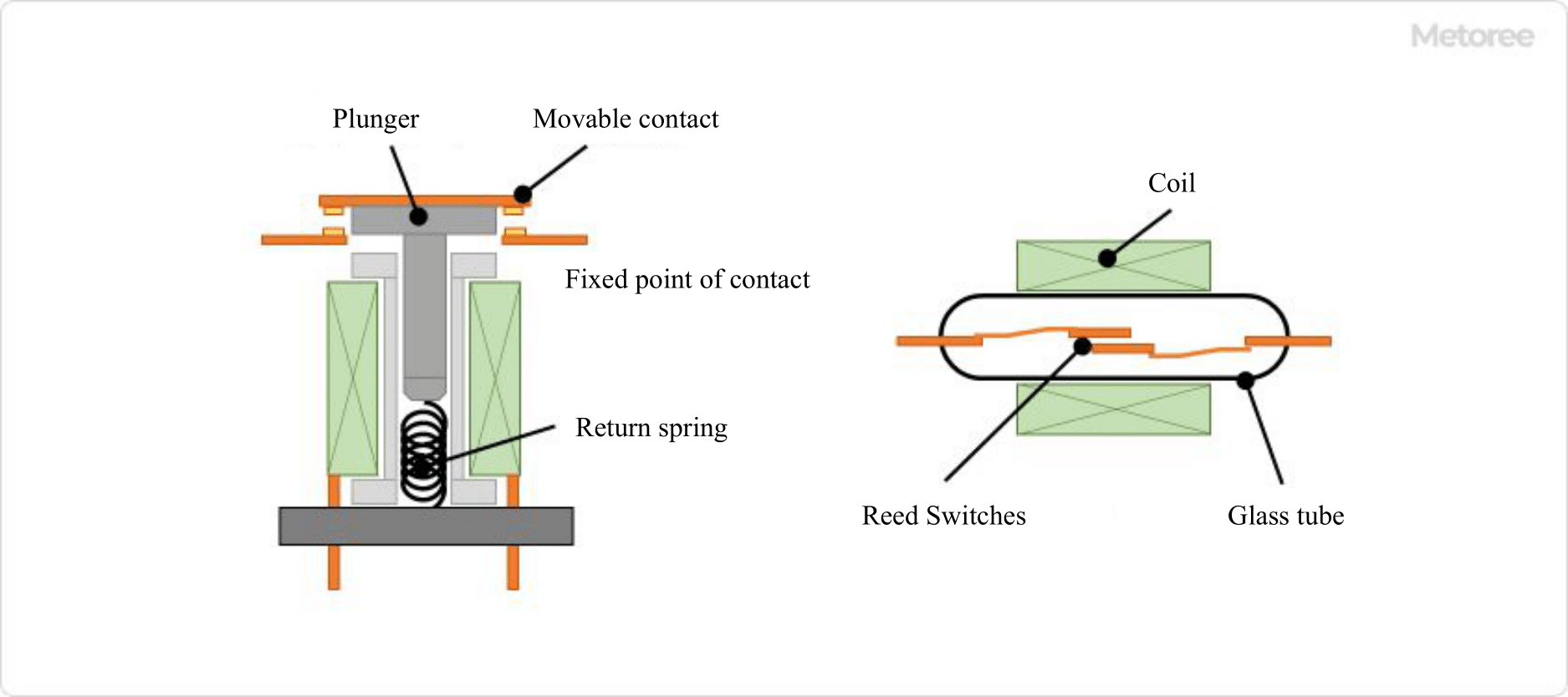

A self-holding solenoid is a solenoid coil with a high-performance permanent magnet that is momentarily energized. The moving part, commonly called a plunger, is attracted and then held in place by the permanent magnet.

With its short energizing time, this linear movable type solenoid is ideal for electrical equipment aiming at ultra energy saving, and is an effective component for extending the operating life of storage batteries and lowering temperature rise, for example. There are two types of solenoids: a one-directional retention type in which the moving part attracts and holds in one direction when the coil is energized, and a two-directional retention type in which the moving part tries to move and hold in two directions by making a series connection of one directional retention type and passing electricity through each coil winding section.

Self-holding solenoids have two types of pole shapes: conical type and horizontal type for one-directional solenoids, and only conical type is standard for two-directional solenoids because the stroke is fixed. Since the magnetic pole shape is used according to the size of stroke and holding force, it is important to carefully check the specifications of each solenoid’s characteristic curve in advance.

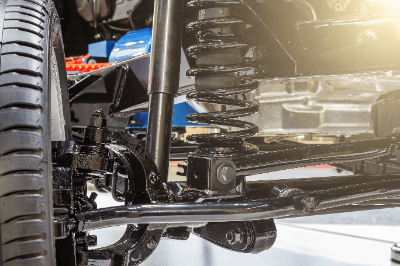

A shock absorber is a device that reduces vibrations in machinery and buildings.

A shock absorber is a device that reduces vibrations in machinery and buildings.

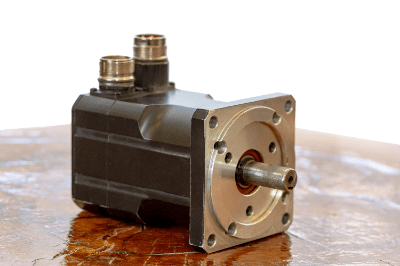

A spindle motor is a motor in which the motor part of the power source and the rotating part are integrated.

A spindle motor is a motor in which the motor part of the power source and the rotating part are integrated.