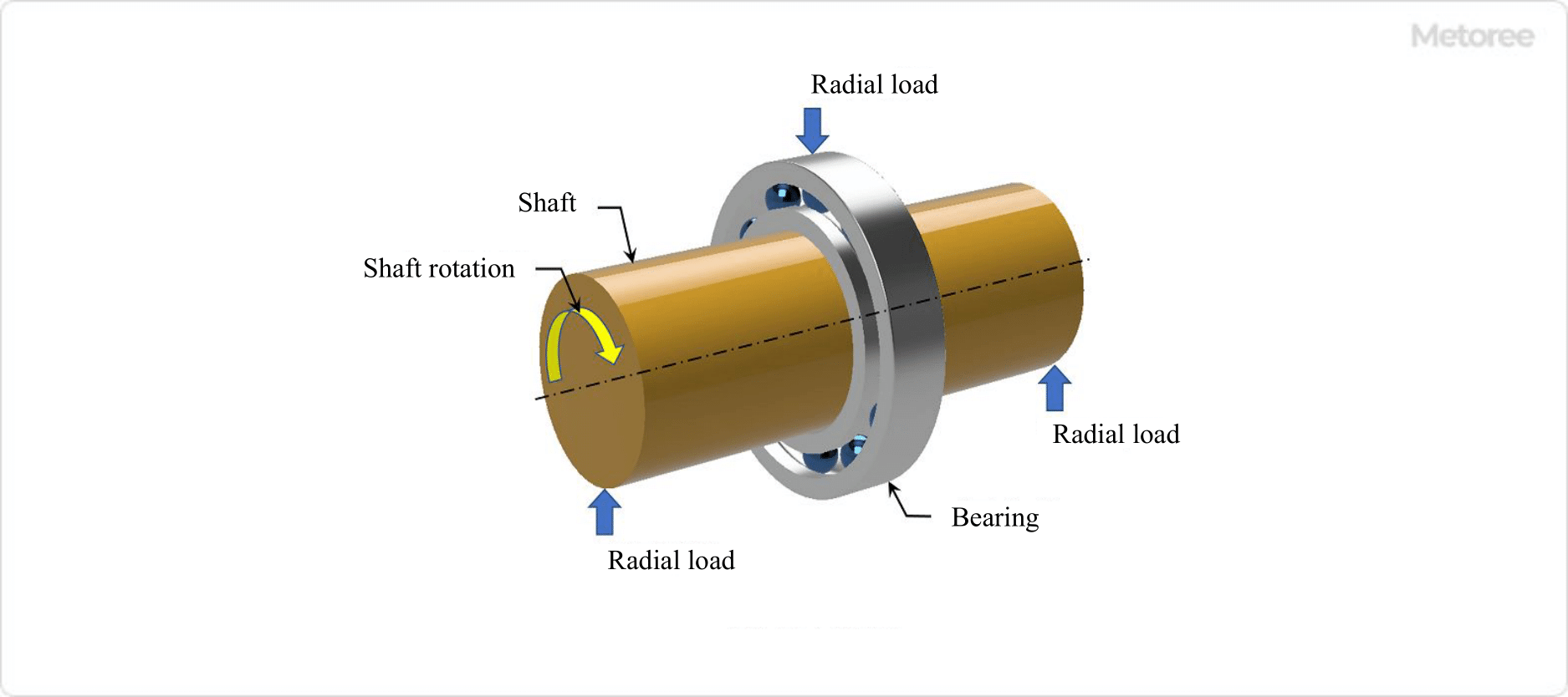

What Is a Radial Bearing?

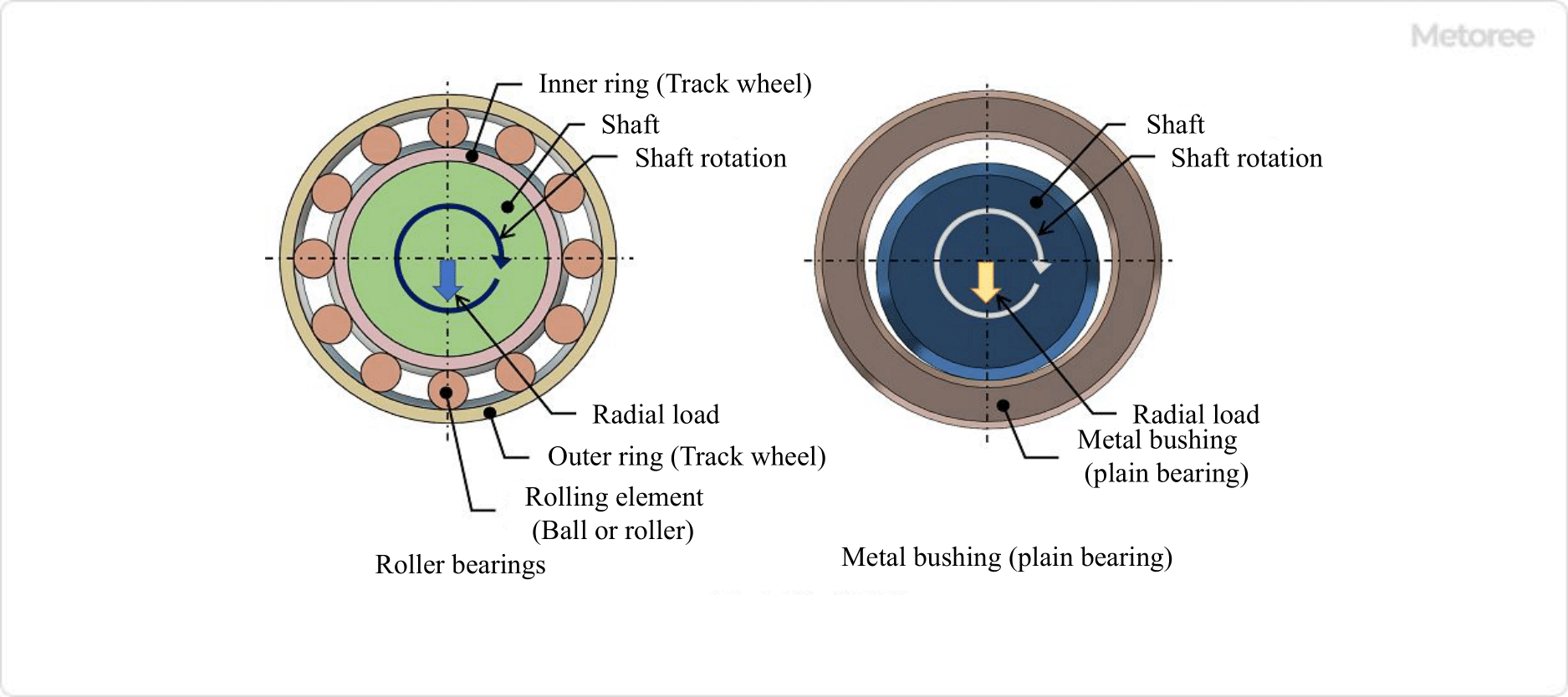

A radial bearing is a bearing that is applied when a load is applied in the radial direction, which is perpendicular to the shaft center of a shaft (rotating shaft).

Normally, selection is based on whether radial or thrust load is applied. However, some types can support both radial and thrust loads, so the selection is mainly based on which load is applied.

Principle of Radial Bearings

Figure1. Radial load

By reducing resistance due to friction on the contact surfaces, the shaft rotates smoothly and supports radial loads.

1. Roller Bearing (Rolling Bearing)

Rolling elements such as balls and rollers roll between the inner ring and outer ring raceways to rotate a shaft with low frictional resistance.

2. Metal, Bushing (Plain Bearing)

Figure2. Radial load

A metal or lubricant-impregnated part with low frictional resistance supports the shaft and allows the shaft to rotate with low frictional resistance.

Uses of Radial Bearings

Radial bearings are used in all kinds of machines with rotating shafts. Various types are used in many places, from familiar household appliances and toys to general industrial machinery and equipment, aircraft, railcars, and automobiles.

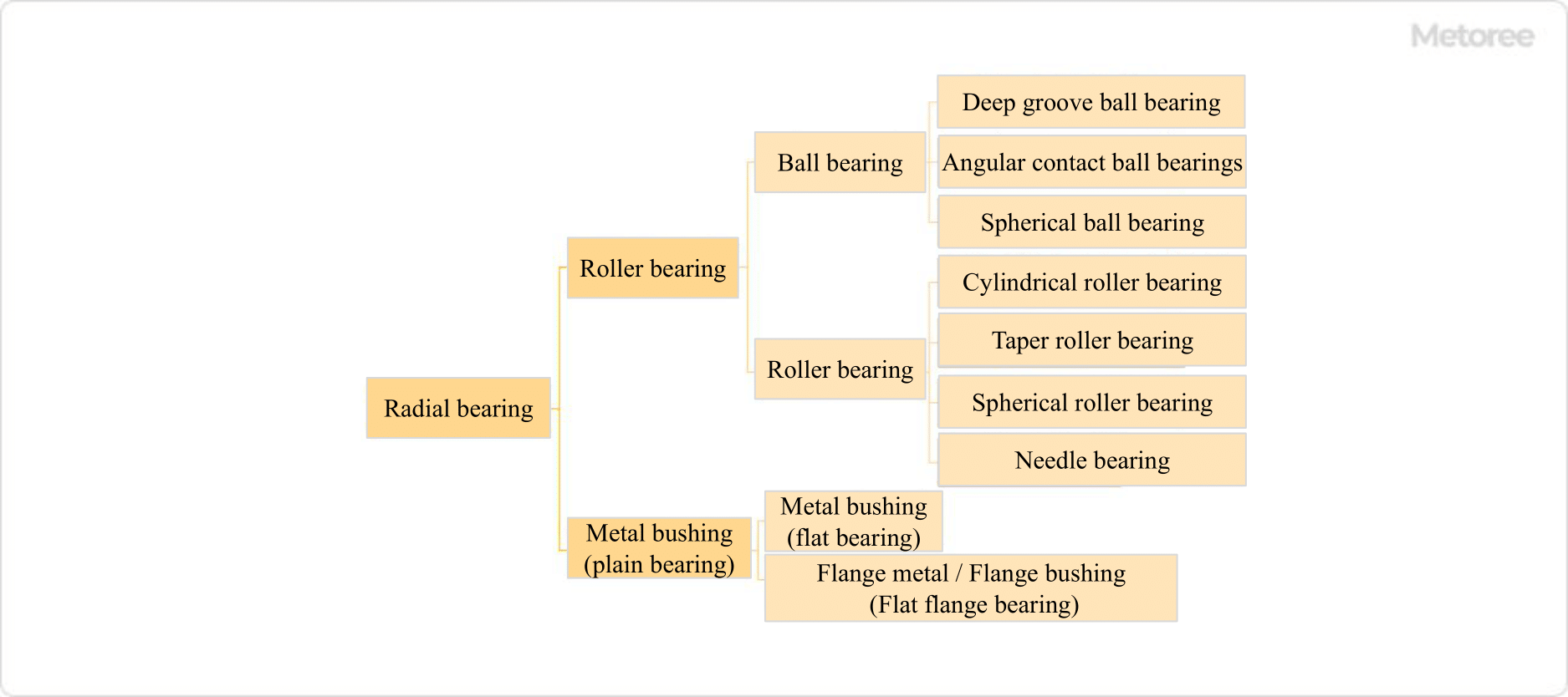

Types of Radial Bearings

There are many types of radial bearings, depending on their structure, function, and application.

Figure3. Types of radial bearings

1. Roller Bearings

a. Ball bearing

-

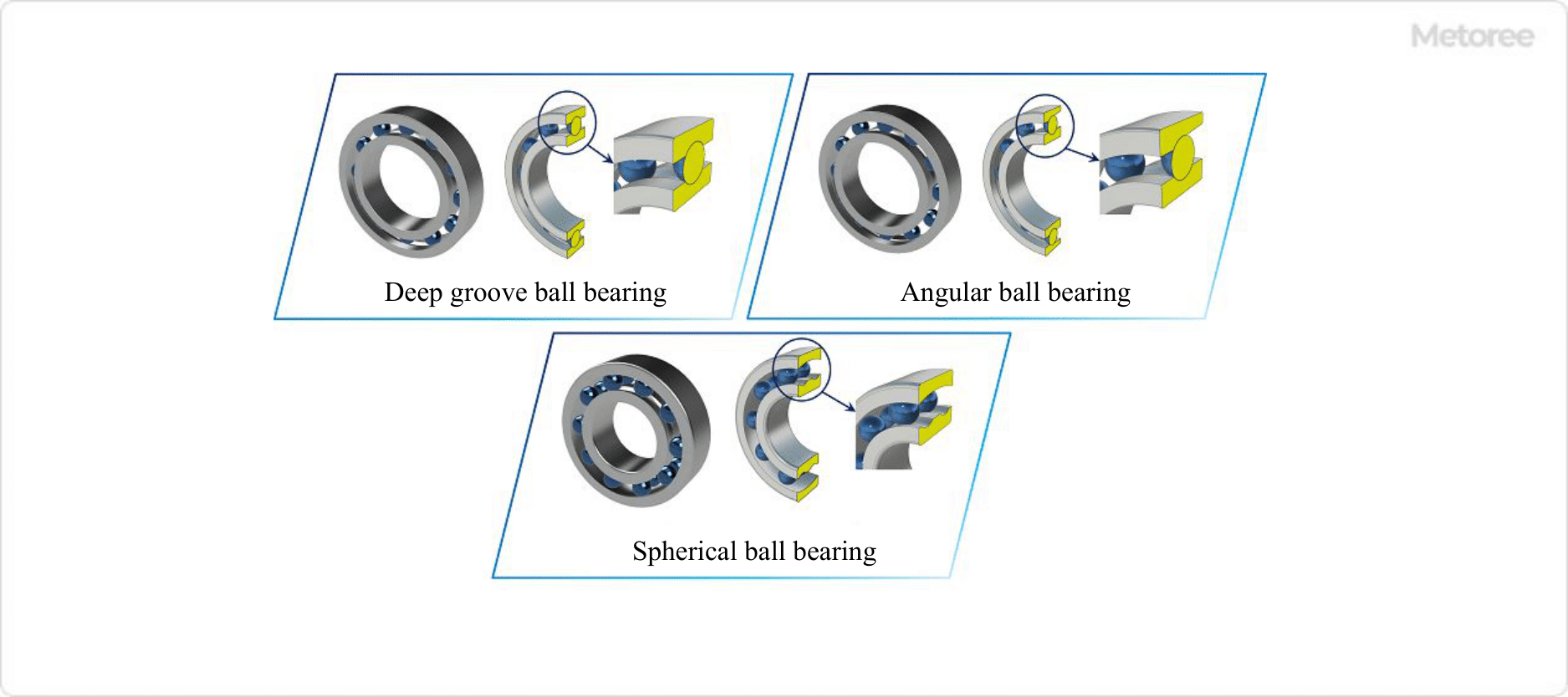

- Deep Groove Ball Bearing

Deep groove ball bearings are the most typical and common type of bearings, featuring low frictional resistance, adaptability to high-speed rotation, low vibration, and low noise. The rolling elements, balls, are placed between the inner ring and outer ring raceways and rotate. Retainers are used to maintain the position of the balls and assist their rotation, resulting in more accurate and smoother rotation. There are open types without ball protection, and sealed and shielded types with grease sealed in the ball portion. - Angular Contact Ball Bearing

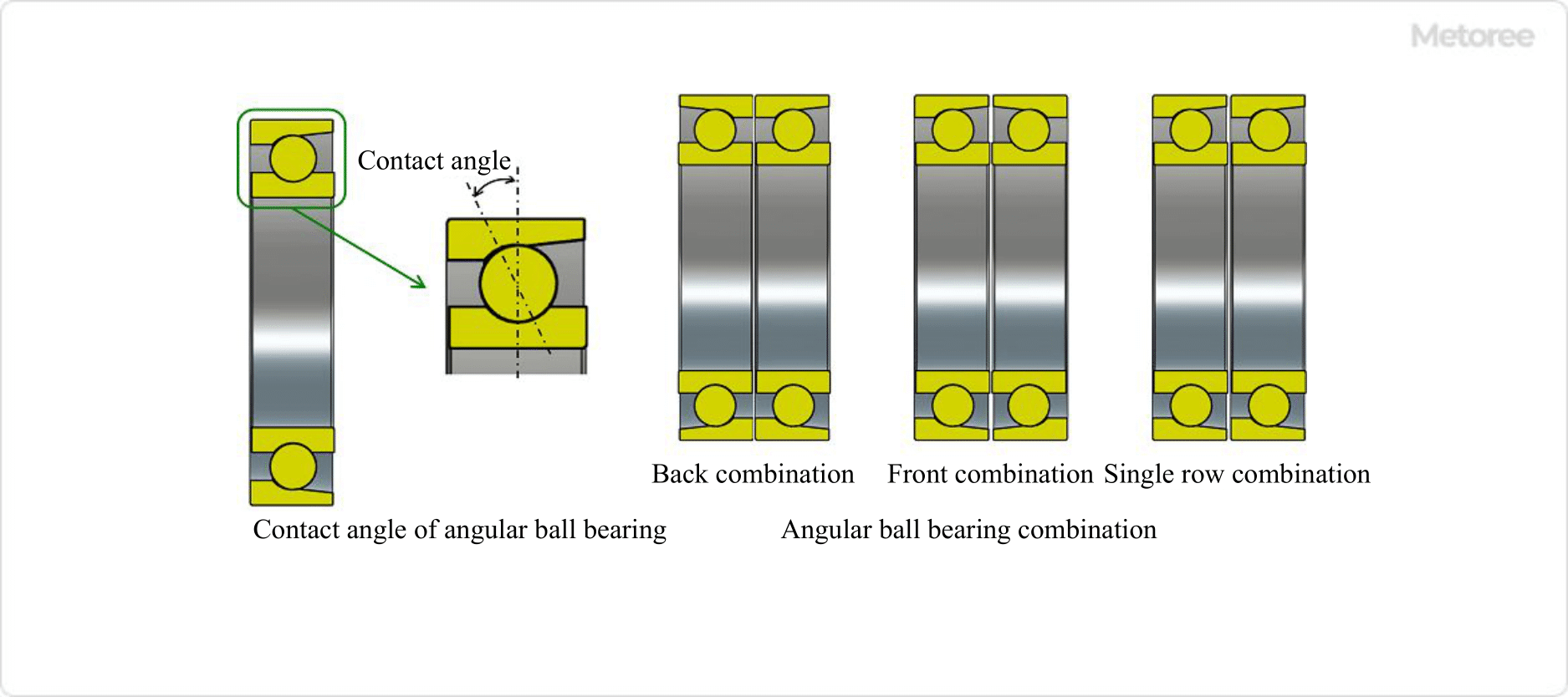

In an angular contact ball bearing, the straight line connecting the contact points of the outer ring, inner ring, and balls are at an angle to the radial direction. This is called the contact angle, which can be 15, 30, or 40 degrees. This contact angle is suitable for axial loads in one direction or combined loads with radial loads, and for high-precision shaft rotation.

Normally, when a thrust load is applied, a single row type of 2 (double row) to 4 (quadruple row) bearings is used in combination. Double-row angular contact ball bearings have an integral inner ring and outer ring structure and can be used individually even when a thrust load is applied.

- Deep Groove Ball Bearing

Figure4. Angular ball bearing

- Spherical Ball Bearing

A spherical ball bearing has a spherical raceway center on the inside of the outer ring and two rows of raceway grooves on the outside of the inner ring. The inner ring ball retainer can rotate at a certain degree of inclination concerning the outer ring.

Therefore, any misalignment due to bearing mounting or machining errors in the shaft or housing is automatically adjusted. However, they cannot support very large thrust loads.

Figure5. Ball bearing

b. Roller bearings

-

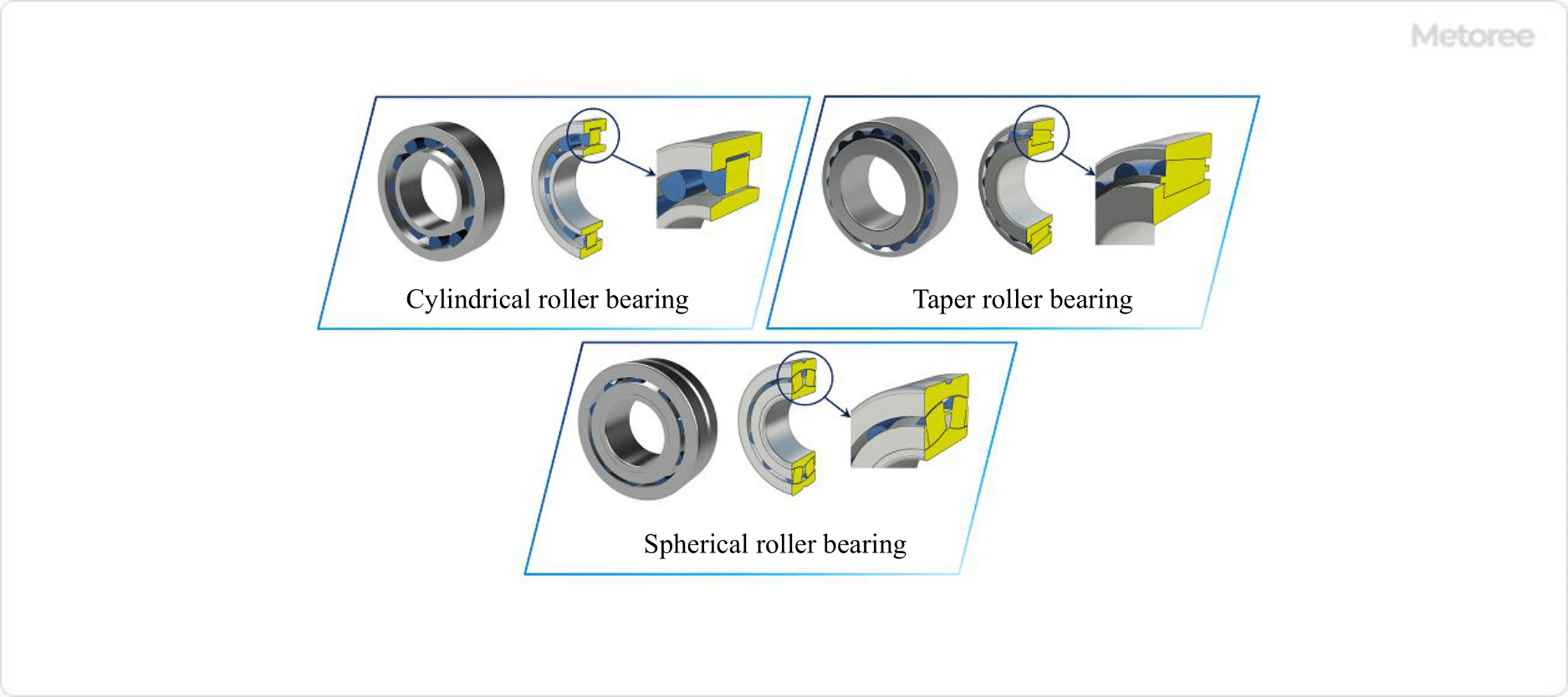

- Cylindrical roller bearings

Cylindrical roller bearings can support large radial loads because the rolling element rollers are cylindrical in shape and the inner ring, roller, and outer ring raceways are in linear contact. The rollers are guided by the inner ring and outer ring brims and can rotate stably, making them suitable for high-speed rotation. Some bearings can support thrust loads in one or both directions. - Tapered roller bearings

Tapered roller bearings have a tapered rolling element roller outline, with the apex of the tapered roller and the raceways of the inner and outer rings intersecting at a single point on the center line of the entire bearing.

The rollers rotate in a true rolling motion on the inner ring and outer ring raceways. They are also guided by the composite external force due to the inner ring and outer ring raceways, which press against the inner ring collar. - Spherical roller bearings

In a spherical roller bearing, the rolling element roller outline is barrel-shaped, and the center of the outer ring raceway and the center of the entire bearing are coincident. Like spherical ball bearings, they are self-aligning. It can support radial loads, thrust loads in both directions and a combination of these loads. They can also be used in applications where vibration or impact forces are applied.

- Cylindrical roller bearings

Figure6. Roller bearing

-

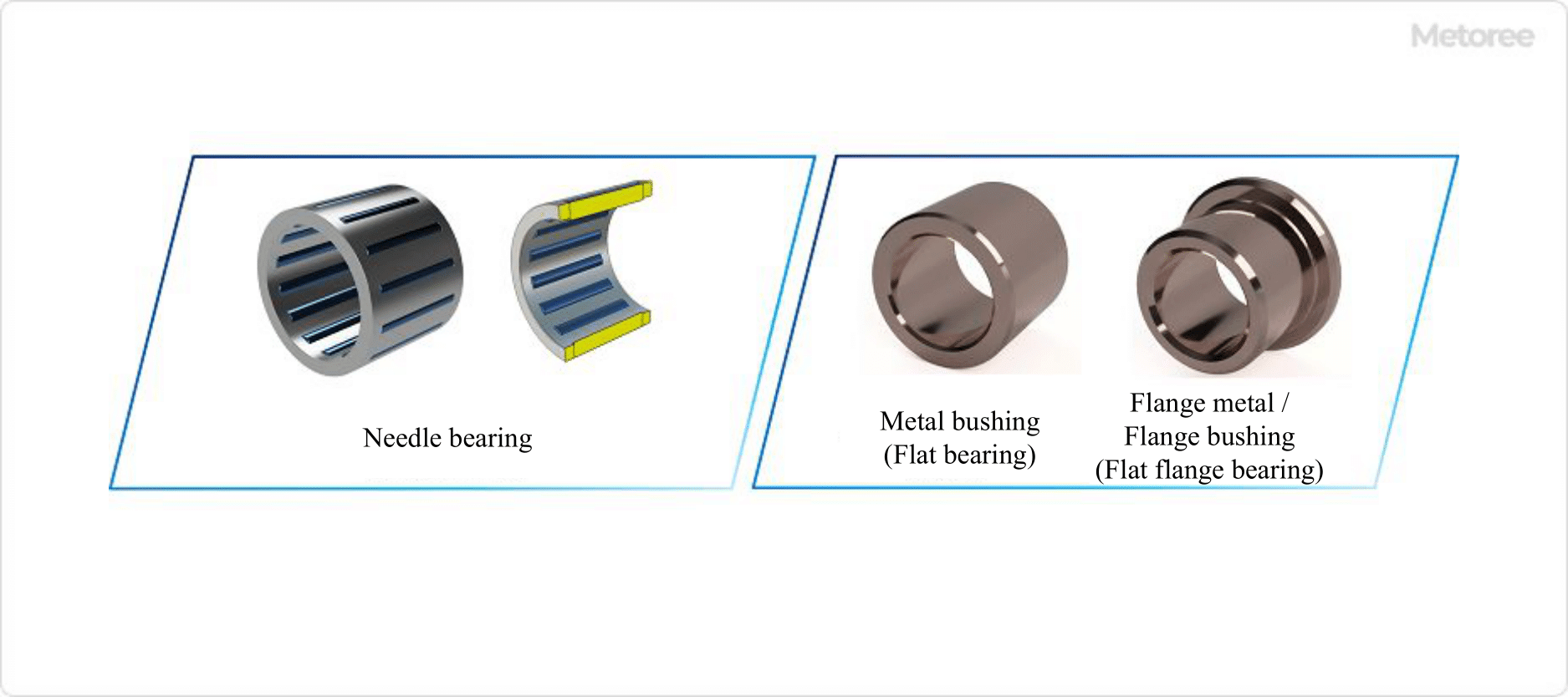

- Needle Roller Bearings

Needle roller bearings are bearings that incorporate rolling elements with long, thin needles (needle rollers). They have a small cross-section, can be installed in a small space, and can support a somewhat large load.

- Needle Roller Bearings

Figure 7. Needle bearing, Metal, Bushing (Flat Flange Bearing)

2. Metal, Bushing (Plain Bearing)

A metal, bushing (plain bearing) is a bearing that directly supports the rotation of a shaft or the linear movement of a component by means of the sliding surface of the bearing. Since the shaft or moving parts are in direct contact with the sliding surfaces of the bearing, frictional forces are high, and frictional heat is generated.

For this reason, the contacting surfaces are lubricated with oil, metal impregnated with lubricant is used for the sliding surfaces of the bearings, and resin materials with excellent lubricating properties are used. Dry bearings are plain bearings that do not use lubricants.

Sliding bearings are relatively inexpensive, flexible in dimension, inexpensive, and easy to use, and various types are used.