メトリーのロゴがひなまつりバージョンになりました。エンジニア・研究者・購買担当者さまなど、産業用製品に関わる方の毎日が少しでも楽しくなるよう引き続き努力して参ります。

過去のロゴ

お正月

クリスマス

ハロウィーン

メトリーのロゴがひなまつりバージョンになりました。エンジニア・研究者・購買担当者さまなど、産業用製品に関わる方の毎日が少しでも楽しくなるよう引き続き努力して参ります。

お正月

クリスマス

ハロウィーン

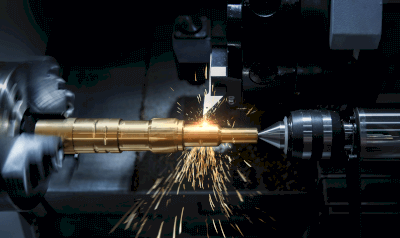

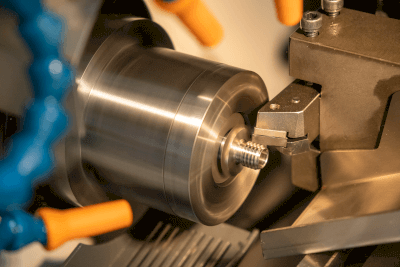

Turning is a machining process where a cutting tool, often referred to as a bit, shapes a rotating workpiece on a lathe. This process is commonly known as lathe turning, is used to produce symmetrical objects with tools chosen based on the desired outcome.

Turning excels in producing cylindrical products such as screws, bolts, shafts, and nipples. Its versatility allows for complex shapes through various bits and precise surface specifications by adjusting the rotation speed. Turning is indispensable in manufacturing precision components for devices like smartphones and automotive parts.

The process involves securing a cylindrical workpiece on a lathe and cutting its periphery and sides with a high-speed rotating tool. Selecting the right tool is crucial for achieving the desired shape and dimensions. Efficiency and quality in turning depend on balancing lathe speed, spindle speed, and the bit’s depth. Adjustments to these parameters influence machining time, accuracy, and tool longevity. Moreover, setting the correct depth of cut is essential to prevent defects caused by excessive cutting heat and frictional resistance.

This method focuses on shaping the outer circumference of a workpiece, encompassing techniques like outer rounding, step cutting, taper cutting, curved surface cutting, grooving, butt cutting, and knurling.

End-face machining targets the workpiece’s end, involving end face grinding, front face grinding, and chamfering.

Drilling involves creating holes, either by pressing a drill against the workpiece’s end face for initial drilling or enlarging an existing hole’s diameter through boring.

Also known as threading, this process creates threads along a workpiece’s periphery or within a hole, including external and internal threading.

Using profile-specific turning tools, profile machining cuts even complex shapes efficiently, according to predefined specifications.

Turning operations utilize various bits, including single-edge, sword, thrusting, threading, knurling, and rotary tools, each designed for specific tasks like shaping external forms, cutting through workpieces, threading, knurling, and more.

Bits are categorized based on their structure into disposable, brazed, and solid types.

The shape of chips produced during turning, such as flow, shear, swell, and cracked types, provides insights into the machining process’s efficiency and potential issues, guiding adjustments for optimal outcomes.

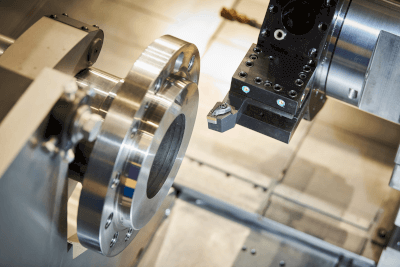

Flanging involves creating a protruding cylindrical part on a component to enhance attachment and strength. This term, originating from the French “roulette” for “something small and turning,” plays a crucial role in mechanics, electronics, building materials, and fluid-carrying pipe connections to prevent leaks and ensure compatibility.

Flanging is critical in applications requiring secure connections without slippage, such as in building drainage systems, automobile axles and exhaust pipes, and the anti-breakaway collars in railway vehicles.

Flanging incorporates standard machining processes like turning, cutting, and sheet metal working, with specific techniques tailored for creating flanges.

Applied to round parts, this method forms the flange’s basic shape, with additional steps for bolt threading holes and threading as needed.

This method is preferable for square flanges or those with complex geometries.

Sheet metal flanges are shaped through press bending or drawing.

Adjustable for different angles, V-bending, L-bending, and U-bending techniques are selected based on the flange’s intended application.

Utilizes a die and blank holder to shape parts, including flange formation, ideal for container production.

Flanges can be bent, shrunk, extended, or composed, each offering unique geometries and challenges.

A straightforward process bending the end of a blank, typically producing straight processing lines.

Features a convex arc, requiring attention to prevent wrinkles and sagging during machining of fan-shaped ends.

Forms a concave arc, stretching the material and necessitating care to avoid cracking.

A complex process combining bending, shrinking, and stretching to achieve a constant flange height with arbitrary shapes.

Flanging enables easy creation of screw holes and strong welding connections, particularly beneficial for curved surfaces where dirt accumulation is minimized. However, it poses challenges with soft materials and thick plates due to deformation risks and high loads. Limited threading may also lead to thread wear over time, suggesting alternative methods for enhanced durability.

A threading service refer to the threading of screws used in various fields.

There are two types of threads: male threads (like bolts) and female threads (female threads with a groove cut on the inside of the nut).

The diameter and pitch of the screw specifications are determined by the standards that govern them.

There are two types of regulations, ISO metric threads and ISO inch threads.

Threading services are also used in various ways depending on the application.

Threads can be made of metal, as in the case of bolts and nuts, or of soft materials such as wood.

Wood screws used for wood do not require any threading process prior to screwing in the wood.

Screws used for precision instruments such as watches and clocks are called fine screws, which have a smaller pitch.

Threading services use special tools called a die for male threads and a tap for female threads.

Threading services are performed manually by attaching a handle to a die or a tap.

In the case of machining, the die or tap is fixed to the chuck of a lathe, or a threading machine dedicated to ordinary cutting or threading services are used.

There are two types of threads, right-hand thread (clockwise) and left-hand thread (counterclockwise), depending on the direction of rotation for threading.

Furthermore, by changing the byte to be used, it is possible to handle trapezoidal screws, and by using a byte with a razor blade, it is also possible to cut off the corners of screws and burrs.

In addition, NC machining using an NC lathe allows the user to select a cutting method such as infeed. In addition, plastic processing called rolling and forging is also performed as thread processing that does not generate chips unlike normal cutting. Rolling is used as a processing that can reduce processing time.

In the case of cutting, various shapes of threads can be manufactured by changing dies and taps using machine tools such as lathes, milling machines, and machining centers. In the case of rolling, the initial investment is high because it is necessary to prepare dies and taps that match the specifications and shape of the target product using a rolling machine. However, rolling has the advantage of shortening the processing time and increasing the durability of the tool. Based on these characteristics, cutting is suitable for processing small-lot, high-variety screws, while rolling is suitable for mass-producing screws.

Forged metal material has a metallurgical flow called fiber flow. Cutting cuts this fiber flow, resulting in a loss of screw strength. On the other hand, thread strength is not lost in the thread rolling process because fiber flow is not cut.

As the name implies, cutting produces chips because the material is cut. On the other hand, thread rolling does not produce chips because it deforms the material by applying pressure. Therefore, form rolling is more environmentally friendly and less wasteful than cutting.

Polycarbonate machining encompasses various processes such as cutting, bending, and welding of polycarbonate, a versatile thermoplastic resin. This material is available in three types of sheet: flat, hollow, and corrugated.

Notable for its excellent impact resistance — 50 times greater than acrylic — and durability against weather elements, polycarbonate is self-extinguishing and boasts high transparency. However, it is susceptible to stress corrosion from organic solvents, which restricts the use of solvent-based adhesives, and its surface is prone to scratching.

Polycarbonate machining is pivotal in producing components that metals cannot easily create, including various cutting, shaping, bending, and welding applications. Despite its hardness, which presents both advantages and challenges during machining, ensuring smooth, chamfered edges post-cutting is crucial to avoid sharpness. Utilized for its transparency, machined polycarbonate products include eyeglass lenses, smartphone cases, and clear partitions.

Machining polycarbonate primarily involves cutting, chamfering, bending, and bonding. Welding is feasible but requires specialized hot-air welding equipment, as typical metal welding tools are unsuitable.

Cutting is performed using acrylic cutters, disk grinders for small quantities, and metal scissors for thin, flat sheets.

Bending polycarbonate without heating involves techniques similar to fitting into grooves, akin to aluminum sash processes.

Compared to metals, cutting and lathing polycarbonate is relatively straightforward, allowing for more intricate designs and cost-effective production.

Bonding is achievable through solvent or adhesive methods, though the choice of solvent is crucial to maintaining transparency and integrity.

Polycarbonate machining utilizes NC data from product drawings to set various parameters such as speed, direction, and tool rotation. Materials are cut slightly larger than needed, placed on an NC router, and processed based on NC data. Post-processing includes burr removal and finishing, with final inspections ensuring accurate dimensions and hole diameters.

Polycarbonate resin, an amorphous thermoplastic, features a carbonate ester structure in its molecular makeup, primarily produced using bisphenol A.

As a standout engineering plastic, polycarbonate excels in impact resistance, being significantly tougher than glass and acrylic. It is flame-retardant, hygienic, and performs reliably across a broad temperature range. With a heat resistance of 248 °F (120 °C) and light transmission comparable to glass, polycarbonate is a preferred choice for transparent applications. Its weaknesses include sensitivity to alkalis, organic solvents, and limited chemical resistance, leading to potential cracking and deformation. To mitigate these drawbacks, alloying with ABS or crystalline resins like PBT and PET can enhance flowability and chemical resistance.

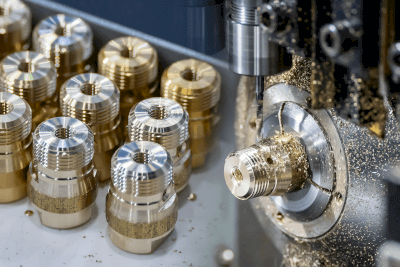

Brass machining involves using brass materials in various processing methods to create diverse products. The main types include cutting, casting, bending, and welding.

Known for its high ductility, brass does not easily break when stretched, making it suitable for stretching into plates or bending into thin wires. Its excellent hot castability also facilitates easier processing when heated, and its cutting workability makes it a preferred material in parts for watches and precision instruments.

Brass is commonly used to manufacture machine parts, bolts, and nuts, which require precise cutting and bending, thanks to its outstanding machining properties. Beyond its functional advantages, the aesthetic appeal of brass makes it a popular choice in various non-industrial products as well.

Brass is also used in accessories, electrical outlets, and wiring, leveraging its high electrical conductivity. Its application extends to brass instruments, water pipes, architectural parts, and furniture fittings, among others.

There are five key methods in brass machining:

With its high machinability, brass is ideal for precision cutting using milling machines or lathes. This method is essential for producing clocks, machine parts, screws, and valves requiring precision machining.

Brass’s high hot forgeability allows for effective cast machining. Cast brass offers manufacturing flexibility but can be prone to air bubble formation, which may affect strength.

Brass can be machined using laser, shearing, press, or chip saw. Laser cutting is particularly popular due to its processing speed and versatility.

Brass bending is achieved through press working or press braking, producing stronger bends compared to those made by cutting.

Welding brass is challenging due to its high thermal conductivity. Silver soldering, which melts at lower temperatures than brass, is often employed.

Despite its advantages, brass is susceptible to moisture and oxidation, often leading to a surface covered with oxidized copper. To prevent this, plating or clear coat treatments are applied. Additionally, brass is prone to deformation, warping, and burr formation during cutting, requiring careful post-processing maintenance.

Aluminum bending is a method used to bend aluminum sheets and other materials into various parts and products. The three main types are roll bending, press bending, and bender bending.

Aluminum, being softer and lighter than steel, offers excellent workability. However, due to its less tenacious nature, it is prone to cracking when bent with too small a radius and can stretch, necessitating careful consideration of thickness, material type, and bending radius in the design and process.

The precision of aluminum bending products largely depends on the manufacturer’s and operator’s skills. The capabilities and limitations of the processing machine also vary.

Aluminum bending is utilized in various aluminum products. Its lightness and ease of processing make it suitable for diverse applications, from aluminum cans to spaceships.

For example, aluminum sheets processed by roll bending are used to wrap around round columns in buildings and for plant piping. Bender bending or press bending creates items like building emblems, signboards, and doors.

Aluminum, being about one-third the mass of steel, is ideal for products where steel or copper would be too heavy. It is commonly used in lightweight modern smartphones.

Aluminum bending is based on the plastic deformation of aluminum. Roll bending and bender bending form aluminum without a die. However, due to aluminum’s characteristics, caution is needed to avoid cracking and elongation. It’s best to design with as large a bending radius as possible.

Here are the key processes used in aluminum bending:

Roll bending passes a metal sheet through rolls, bending it using the force of the rolls. The shape can be adjusted by changing the distance between the rollers. However, the thickness of aluminum sheets that can be processed varies by machine.

Press bending forms metal by pressing it into a die, with common subcategories including L-shape, U-shape, and V-shape bending. This method is similar to general bending and uses a press-working machine.

Bender bending uses a press machine to bend or fold metal, suitable for thin aluminum sheets, and capable of producing various shapes, including right angles, V-shapes, L-shapes, and complex Z-shapes.

In aluminum bending, it’s crucial to avoid cracking and elongation. Roll bending and bender bending form aluminum without a die, but special attention is needed due to aluminum’s tendency to crack and elongate when stretched. Bending should be perpendicular to the rolling direction and with an increased bending width to prevent cracking.

Additionally, in press bending using dies, aluminum’s softness may result in die wear and surface scratches appearing on the bent product.

Aluminum anodizing is a surface treatment method that produces an oxide film on the aluminum surface.

Aluminum anodizing protect the aluminum surface from corrosion, scratches, and friction.

However, because the naturally formed oxide film is very thin, it can corrode through chemical reactions with other substances. In addition, aluminum is a soft material and its surface is easily scratched. Therefore, the aluminum is anodized to form a thick and durable oxide film.

The aluminum oxide that serves as the surface film is called passivity. Once aluminum oxide is formed, it has a property that does not change, thus protecting the inner aluminum and making the aluminum more resistant to corrosion.

Anodized aluminum becomes more resistant to scratches and friction due to its higher corrosion resistance, abrasion resistance, and hardness. In addition, when dyes are adsorbed on the oxide film-formed surface, a variety of colors can be applied, thus beautifying the appearance.

Aluminum is used for cooking utensils such as pots, kettles, and bats because of its high thermal conductivity, light weight, and portability. In addition, because of its high workability, it is also used for construction materials such as doors and sashes that are used outdoors for a long time, and for industrial parts such as automobiles, trains, and airplanes. It is often used in products that are used outdoors.

Anodizing (anodic oxidation treatment) forms an oxide film on aluminum through electrolysis in an electrolytic solution (sulfuric or oxalic acid). When the product to be treated is attached to the anode side and energized, oxygen is generated by electrolysis and forms a film on the aluminum surface.

During anodizing, the oxidation reaction and the dissolution reaction of sulfate ions occur simultaneously on the aluminum substrate. Numerous micropores are formed in the formed film, and the pores are regularly extended.

Pressurized steam, hot water, or metallic salts are used for sealing treatment. By combining electrolytic conditions such as electrolyte type, concentration, current density, and temperature, as well as the type of aluminum alloy, colors such as silver, black, gold, and amber can be produced, and hard coatings can be created to improve wear resistance.

The oxide film formed by aluminum anodizing are insulating and does not conduct electricity. For this reason, it is used in electronic devices and semiconductor manufacturing equipment that require voltage resistance. In addition, it is used in a wide range of fields such as industrial products, building materials, household goods, decorations, and transportation equipment, taking advantage of its corrosion resistance and water repellency properties.

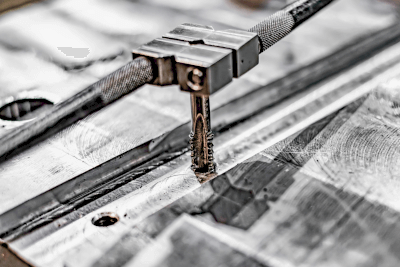

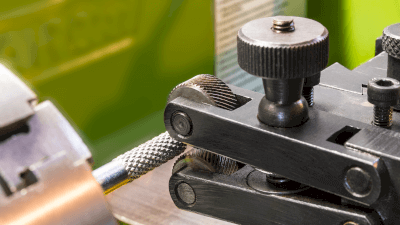

A threading service is a process used to create screw threads. This service can apply to both male screws (common rod-shaped screws) and female screws (internal threads). The interaction between bolts and nuts exemplifies the relationship between male and female screws.

A threading service is a process used to create screw threads. This service can apply to both male screws (common rod-shaped screws) and female screws (internal threads). The interaction between bolts and nuts exemplifies the relationship between male and female screws.

Threading can be performed using cutting techniques with a lathe or through plastic rolling methods.

Female threading involves similar techniques to male threading: cutting and plastic forming.

Threading services cater to various shapes, such as triangular, square, or trapezoidal threads, with triangular screws commonly used in machine parts. These services ensure threads conform to specific standards, like metric coarse threads, where the distance between adjacent threads is known as the pitch.

For smaller quantities, tools like dies and taps are used, while large-scale production employs processes such as cutting and threading using lathes and threading machines.

Threads can be manufactured either by plastic forming or cutting service.

Plastic forming, which doesn’t produce cutting chips, includes methods like thread rolling. Thread rolling can be performed using flat dies, round dies, or segment dies. However, the process requires time for mold design and setup.

Threading services may also be executed using forging dies.

Cutting services are versatile on a single lathe but are not ideal for mass production. External thread turning is used for male threads, while internal thread turning creates female threads. NC lathes, which automate all cutting operations, have become increasingly popular.

Threading machines, specialized for threading services, are used for items like anchor bolts in construction. The drawbacks of cutting include the generation of a large amount of waste, high costs due to cutting tools, and the time needed for tool changes.

Knurling is a manufacturing process where a knurling tool is pressed against a metal surface to create fine bumps, enhancing grip. This technique is derived from the French word “roulette,” meaning “something small and turning,” and is utilized across various industries, including automotive, aircraft, and medical equipment, to prevent slippage.

There are two primary knurling methods: cutting, which removes the surface of the material, and rolling, where material is deformed by pressure without removing material.

Knurling adds surface texture to cylindrical objects such as rods, screw heads, and handles to improve grip and prevent them from slipping. It is applicable to metals like brass, iron, stainless steel, and aluminum, providing flat or angular surface patterns.

Knurled products find applications in a wide range of domains, from machinery to everyday items like automobiles, aircraft, home appliances, and mobile phones.

Knurling can be performed either by cutting or rolling:

This method involves pressing a knurling tool against the material to remove it, forming a pattern. It generates chips but places less load on the machine, allowing for higher quality machining. The process does not deform the material, resulting in a smaller diameter post-processing.

Forming applies pressure while rotating the knurling tool, causing plastic deformation and pattern formation on the material without producing chips. This method increases the diameter of the material from its original size.

Knurling is primarily used to enhance grip, producing two main types of patterns:

Produces straight, linear patterns effective for preventing rotational slippage.

Creates diamond-shaped patterns, providing anti-slip properties in both circumferential and axial directions.

Each knurling type has its advantages and disadvantages:

Suitable for machining thin, long materials without causing bulging, this method minimizes machine and material load, allowing continuous cutting. It’s applicable to various materials, including resin. However, machining materials with steps can be challenging due to tool interference, and tool wear requires careful management during mass production.

Capable of machining up to the edge of stepped materials and increasing post-machining diameter. While this method can reduce machining time and costs, it is unsuitable for long workpieces due to high resistance and material limitations.

Suitable materials for knurling include aluminum, copper, titanium, brass, resin, cast iron, and various steels. While cutting is versatile, processing hard or brittle materials such as titanium and cast iron or certain resins can be challenging.