What Is a Hydraulic Gantry?

A hydraulic gantry is a lifting machine that consists of jacks (legs) equipped with a telescoping mechanism, such as hydraulic cylinders, and beams arranged in a gantry shape. It moves heavy objects below or above the beam by extending and retracting the jacks.

Hydraulic gantries are called “gantries” because their structure resembles a gate. They are also known as “bridge lifters” due to their shape. The term “gantry” refers to a structure with horizontal beams supported by multiple vertical legs.

The traveling frame is equipped with wheels, allowing the gantry to move while lifting a load. Some models can also shift horizontally. There are a wide variety of gantries, from small ones with a lifting capacity of about 1 ton to large ones capable of lifting over 1,000 tons. They also differ in beam length, lift height, and stroke. These machines are ideal for safely moving heavy loads in environments where cranes cannot be used due to building constraints or limited space.

Uses of Hydraulic Gantry

A hydraulic gantry is often used to move heavy objects in confined spaces where cranes are impractical, such as in buildings with low ceilings, tunnels, or areas with overhead obstructions like electric cables. They are also useful in buildings where overhead cranes cannot be installed, such as in leased buildings or structures that are not strong enough to support cranes.

Hydraulic gantries lift objects by extending and retracting jacks. Because the load can be directly suspended from a special hanger, the lifting loss is minimal. The beam height can also be adjusted to navigate obstacles overhead.

When moving long or heavy loads, using cranes or forklifts can be unstable and dangerous. In such cases, two hydraulic gantries can be used for safer and more efficient handling. Different types and sizes of gantries are used depending on the working environment.

Principle of Hydraulic Gantry

A hydraulic gantry uses a hydraulic or electric jack powered by electricity, with a beam mounted at the top. The beam may have special hangers (rings) to hold the load or a deck on which the load is placed.

For hanger types, the load is positioned under the beam. The jack is retracted to lower the beam, the load is suspended from the hangers, and then raised.

For deck types, the deck is lowered by retracting the jacks. The load is placed on the deck, and then it is raised.

Larger gantries move using motor-powered wheels at the base of the jacks. Smaller models may be moved manually. The gantry is operated via a switch panel connected to a control unit.

Types of Hydraulic Gantry

Hydraulic gantries are available in various types, including beam-lifting and deck-lifting models. They differ in terms of lifting capacity, stroke, and span, depending on the weight and size of the cargo.

1. Lift: The distance from the ground (or the top of the rail, if present) to the bottom of the hanger hole.

2. Stroke: The total travel distance from full extension to full retraction of the jack.

3. Span: The horizontal distance between the centers of the left and right jacks.

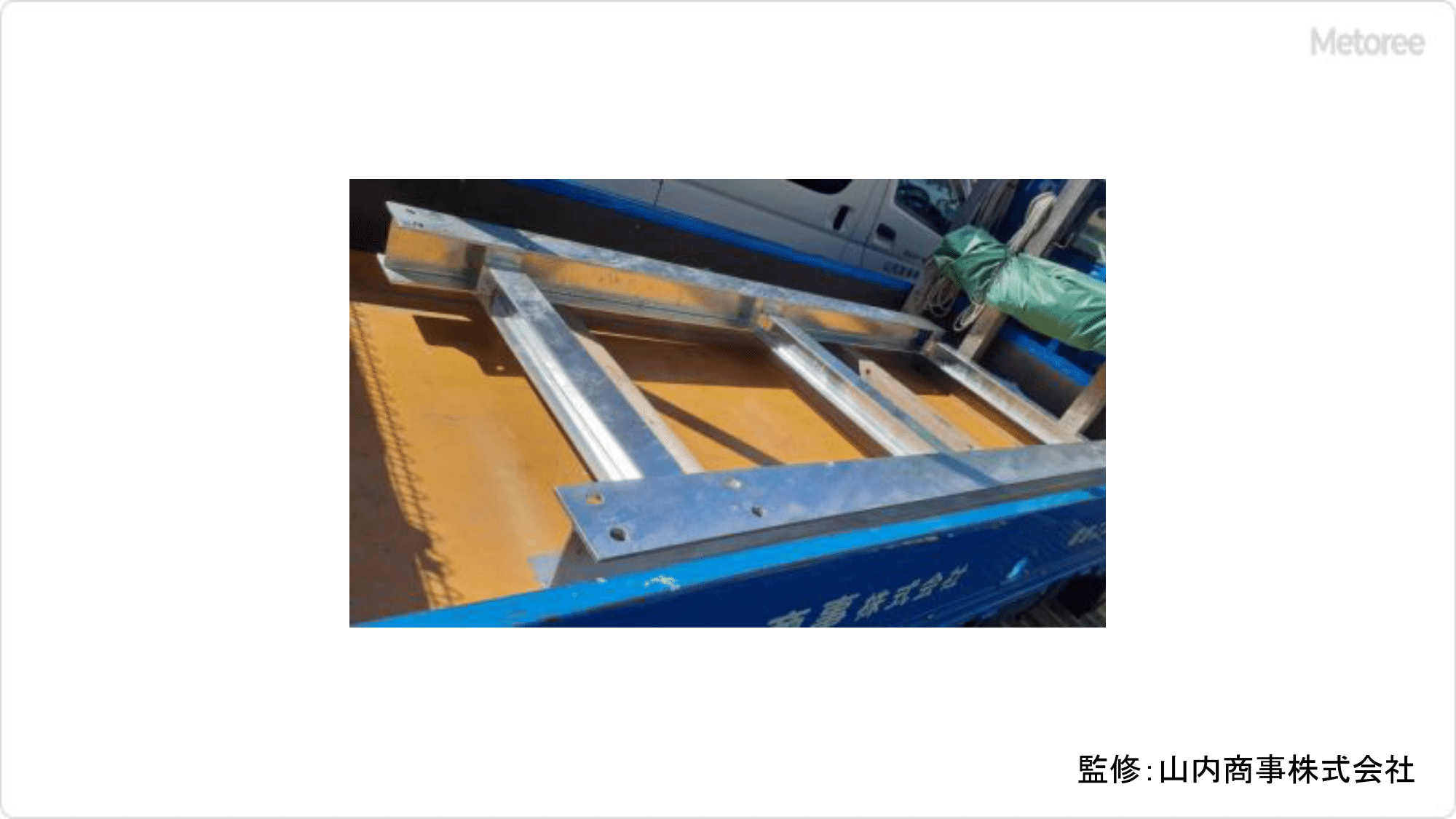

Hydraulic gantries can be disassembled and reassembled, allowing them to be transported to various locations and used as needed. This improves the equipment’s investment efficiency and flexibility.

How to Select a Hydraulic Gantry

Hydraulic gantries are used to lift heavy loads that cannot be handled manually. Therefore, safety is the top priority in selecting and operating a gantry lifter. Companies may not be able to manage accidents or breakdowns on their own.

When choosing a gantry, consider not only the machine’s specifications but also the proposed installation method for the specific site conditions and the availability of maintenance and support services.

-のコピー-のコピー-3.png)