What Is Cemented Carbide?

Cemented carbide is a generic term for composite alloys made by adding iron-based metals to metals in groups 4-6 of the periodic table.

In particular, WC-Co alloys, in which cobalt is bonded to tungsten carbide, are commonly used. They are extremely hard and can maintain their room temperature hardness even at high temperatures. They are also strong and resistant to external forces, such as bending.

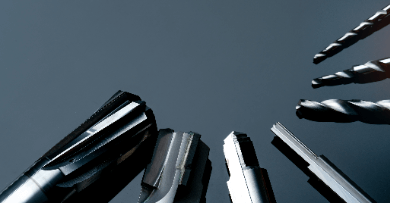

Uses of Cemented Carbide

Cemented carbides are used in fields where wear resistance is required. Specifically, they are used in cutting and polishing tools for glass, plastic, and metal processing. They are also suitable for applications such as drills for drilling holes in rock and concrete, nozzles for industrial products, pipes for electrodes, pins for dot printers, and punch pins.

Cemented carbide is second only to diamond in hardness and maintains its hardness even at high temperatures. It is also characterized by its high strength and resistance to bending under load. They are used in fields where these characteristics can be utilized.

Principle of Cemented Carbide

Cemented carbides are composite alloys made by bonding (sintering) metal oxides of metals belonging to groups 4 to 6 of the periodic table with iron-based metals, as described above.

The following nine metals belonging to groups 4-6 of the periodic table are listed.

- W (Tungsten)

- Cr (Chromium)

- Mo (Molybdenum)

- Ti (Titanium)

- Zr (Zirconium)

- Hf (Hafnium)

- V (Vanadium)

- Nb (Niobium)

- Ta (Tantalum)

Typical ferrous metals are as follows:

- Fe (Iron)

- Co (Cobalt)

- Ni (Nickel)

Among these, WC-Co alloys made by adding cobalt as a binder to tungsten carbide are the most representative.

Cemented Carbide Manufacturing Methods

Cemented carbides are manufactured by a special method called powder metallurgy. This is because the melting point of tungsten carbide, the main material used in cemented carbide, is as high as 2,900℃, making it difficult to melt it like iron.

Powder metallurgy is a manufacturing method in which metal powder is pressed and then hardened. Cemented carbide is manufactured by mixing tungsten carbide metal powder with cobalt or other metal powder as a binder, pressing and hardening the mixture, and then sintering it at a high temperature of 1,300 to 1,500℃.

Various composite alloys can be produced by changing the composition of the metal powder to suit the application. At present, in addition to the “WC-Co series,” there are many other types developed, including the “WC-TiC-Co series,” “WC-TaC-Co series,” and “WC-TiC-TaC-Co series.

Cemented Carbide Machining Methods

Cemented carbides are so hard that they cannot be machined by ordinary methods. Therefore, it is machined either by using diamonds, which are harder than cemented carbide, or by using pulsed electric discharge from a pulsed power source.

1. Machining Using Diamond

Diamond is very expensive, so diamond abrasives are used on a wheel for cutting and polishing. The disadvantage is that the diamond portion to be cut is small, so the cutting is done gradually and the process takes a long time. For this reason, tools with a diamond coating on the cutting tool itself have recently been developed.

2. Electric Discharge Machining

Electrical discharge machining includes wire machining and profile drilling. In wire processing, wires are stretched above and below the material, and the material is cut by an electric discharge from the wires. Shape drilling refers to a method in which the material is placed in a liquid and the electrode is brought close to the material while discharging electricity to melt the metal.

Other Information on Cemented Carbide

Cemented Carbide Standards

Cemented carbide is described as HW-P20, which is a cross between a classification by cutting tool material (HW part) and a classification by work material (P20 part).

This indicates what kind of material and what kind of workpiece can be machined. Cemented carbides mainly composed of tungsten carbides are classified into HW and HF according to the particle size, with HW being those with an average particle size of 1 μm or larger and HF being those with an average particle size of less than 1 μm.

HT and HC are also listed as cemented carbides in the standard. HT refers to cermet, which is mainly made of titanium, tantalum, and niobium carbides and nitrides with a low content of tungsten carbide. HC is a symbol for coated cemented carbide, nitride, oxide, or diamond coated on one or more layers on the surface of cemented carbide.