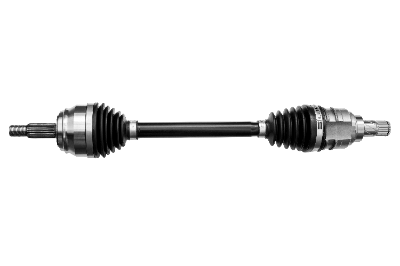

What Is a Driveshaft?

A driveshaft is a rotating shaft used to transmit the power of a prime mover to rotating equipment.

A driveshaft is a rotating shaft used to transmit the power of a prime mover to rotating equipment.

Driveshafts are generally known as automobile driveshafts, but they are also widely used for power transmission in ships, industrial machinery, construction machinery, railcars, and other vehicles.

Driveshafts do not have to be arranged in a straight line from the power section to the transmission section, but can still transmit power by using constant velocity joints.

Driveshafts are especially needed in automobiles to drive wheels that are subject to large vibration displacement.

Uses of Driveshafts

Driveshafts are also most commonly used in automobiles. Driveshafts in automobiles are components that transfer the power of the engine to the wheels.

In front-wheel drive vehicles, power is transmitted from the engine to the wheels via the Driveshaft. In the case of rear-wheel-drive vehicles, power from the engine is transmitted via the propeller shaft to a differential gear in the rear, which drives the wheels using the Driveshaft.

For applications other than automobiles, the propeller shaft is connected to motors for blowers, pumps, compressors, cranes, reduction gears, etc., and to drive shafts for rolling mill rolls and tension reels in steel manufacturing machinery. They are also used as drive shafts for rolls in chemical machinery, hydraulic pump drive shafts in construction machinery, and hydraulic pump drive shafts in truck mixers.

Further applications include work equipment drive shafts for agricultural tractors and drive shafts for machine tools, printing machinery, and paper manufacturing machinery.

Principle of Driveshafts

Driveshafts in automobiles and other equipment usually do not form a straight line from the engine power unit to the wheel power transmission unit. Therefore, constant-velocity joints are installed at both ends of the shaft to smoothly transmit power at a constant velocity even if the shaft is angled.

There are two types of constant velocity joints: fixed type and sliding type.

1. Fixed Type

This type cannot slide in the direction of the drive shaft. The constant velocity joint has parts called the outer race and inner race, and several steel balls are placed inside the outer race and outside the inner race. The steel balls allow the constant velocity joint to be angled.

2. Sliding Type

This type can slide in the direction of the drive shaft. There are two types: One type has grooves on the outer race and inner race that are parallel to the axial direction and can slide in the axial direction. The other type has a three-axis component attached to one of the rotating shafts, each end of which has a roller. When rotated at an operating angle, the rollers roll in grooves inside the housing to enable axial sliding.

Other Information on Driveshafts

1. Life of a Driveshaft

The life of a Driveshaft is generally the time it takes for the constant velocity joint to wear out to the point of noise or breakage. For automobiles, the standard is 200,000 km in terms of mileage.

A symptom of a failing Driveshaft approaching the end of its service life is the production of abnormal noise.

The most common type of vehicles in which abnormal noise can be easily recognized are front-wheel drive (FF) vehicles. When the angle of the constant velocity joint is large due to steering, a rattling noise may occur when accelerating. The cause of the noise is excessive clearance due to wear of the inner race, outer race, and steel balls, which are the key parts of the constant velocity joint.

The main causes of wear are deterioration of lubrication performance due to deterioration or decrease in the amount of grease sealed in the constant velocity joint for lubrication, and accelerated wear due to foreign matter such as sand entering the joint.

Grease deterioration can be caused by aging due to long-term use, early deterioration due to heat generation in the joint caused by continuous high load, and deterioration due to moisture contamination. Most of the causes of low grease level and foreign matter contamination at joints are deterioration or damage to the bellows-like parts called boots that protect the joints.

2. Drive Shaft Boots

Boots protecting joints are mainly manufactured from rubber or flexible resin. The boots are cylindrical bellows-shaped, installed to cover the entire joint and secured with metal bands tightened at both ends.

The main functions of the boot are to retain lubricating grease in the joint and to prevent foreign matter from entering the joint. When inspecting the Driveshaft externally, it is important to check if the boot is torn or if grease is leaking from the fixed part. Reduced lubrication and foreign matter in the joints accelerate wear.

Replacing the boot used to require removal of the Driveshaft from the vehicle body, but now there are split-type boots that can be replaced without removing the boot from the vehicle body.

After the old boot is removed, the new boot, which is split in two, is installed so that it is sandwiched between the joints, and the mating joints are welded together with adhesive and heat to achieve a strength similar to that of conventional products.

When replacing the boot, the grease inside is also replaced with a new one, thus restoring lubrication performance.