What Is a Soap Film Flowmeter?

Figure 1. Various flow meters

A soap film flowmeter is a type of flowmeter that uses a soap film to measure the flow rate to be measured.

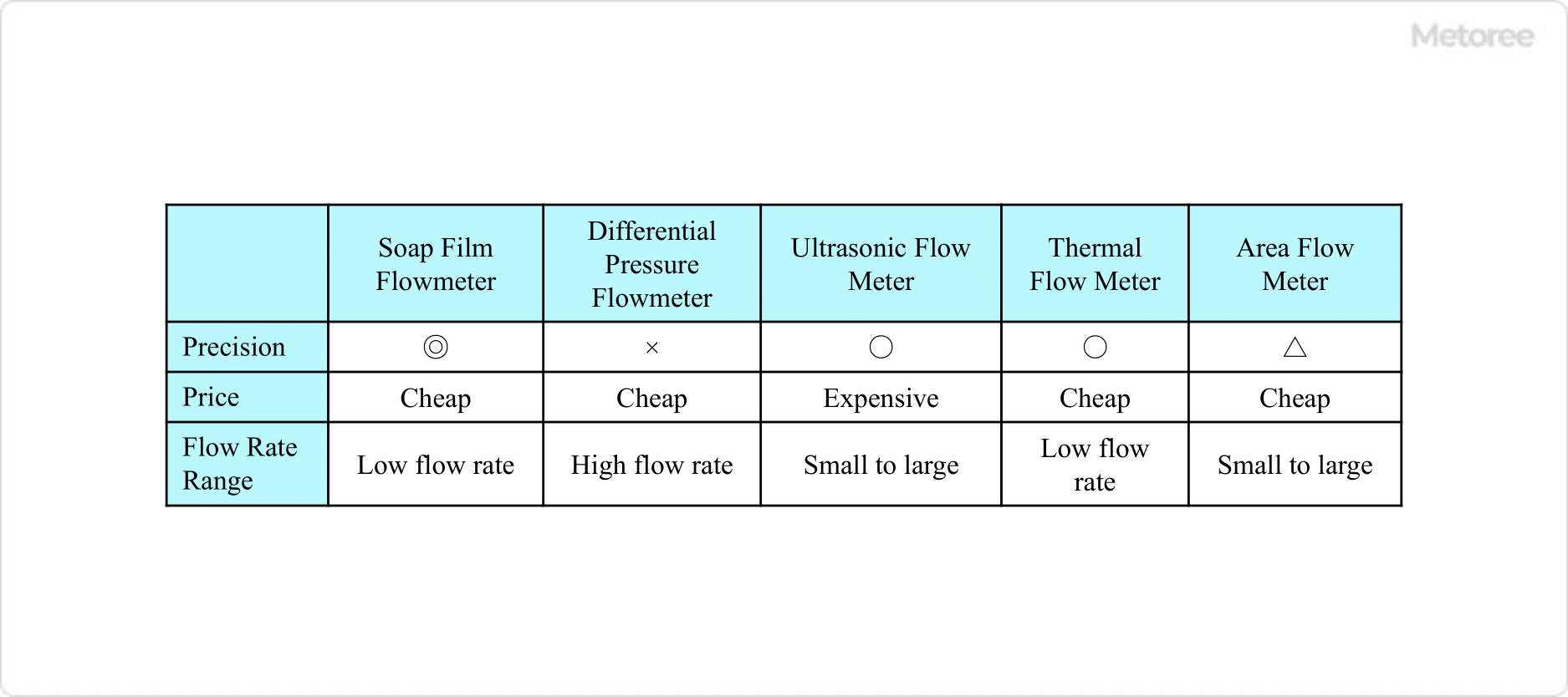

A flowmeter is a measuring instrument that measures flow rate, and there are various types of flowmeters. There are various types of flowmeters, such as ultrasonic flowmeters that use ultrasonic waves to measure the flow rate, differential pressure flowmeters that measure the pressure difference, and hot wire flowmeters that measure the flow rate by placing an electric heating wire inside the pipeline and measuring the amount of heat lost by the fluid in proportion to the flow rate.

Although the vesicle flowmeter measures a small amount of flow, it is a highly accurate and inexpensive flowmeter. Recently, electric annular flowmeters are available that automate all operations at the touch of a button and automatically calculate atmospheric pressure compensation and temperature compensation.

Uses of Soap Film Flowmeters

Soap film flowmeters are used to measure minute gas ventilation and leakage volumes, as well as to calibrate various types of flowmeters. The glass tube used for measurement can be made thinner to enable even more minute measurements.

The soap film flowmeter is characterized by its ability to measure gas flow rates accurately and to measure minute gas flow rates. There are many applications that take advantage of these features.

Another advantage of the soap film flowmeter is that it is small and simple in construction, yet it can visibly measure minute flow rates that you may not even notice are flowing. Flow is invisible, but you can visually confirm that it is indeed flowing.

Principle of Soap Film Flowmeters

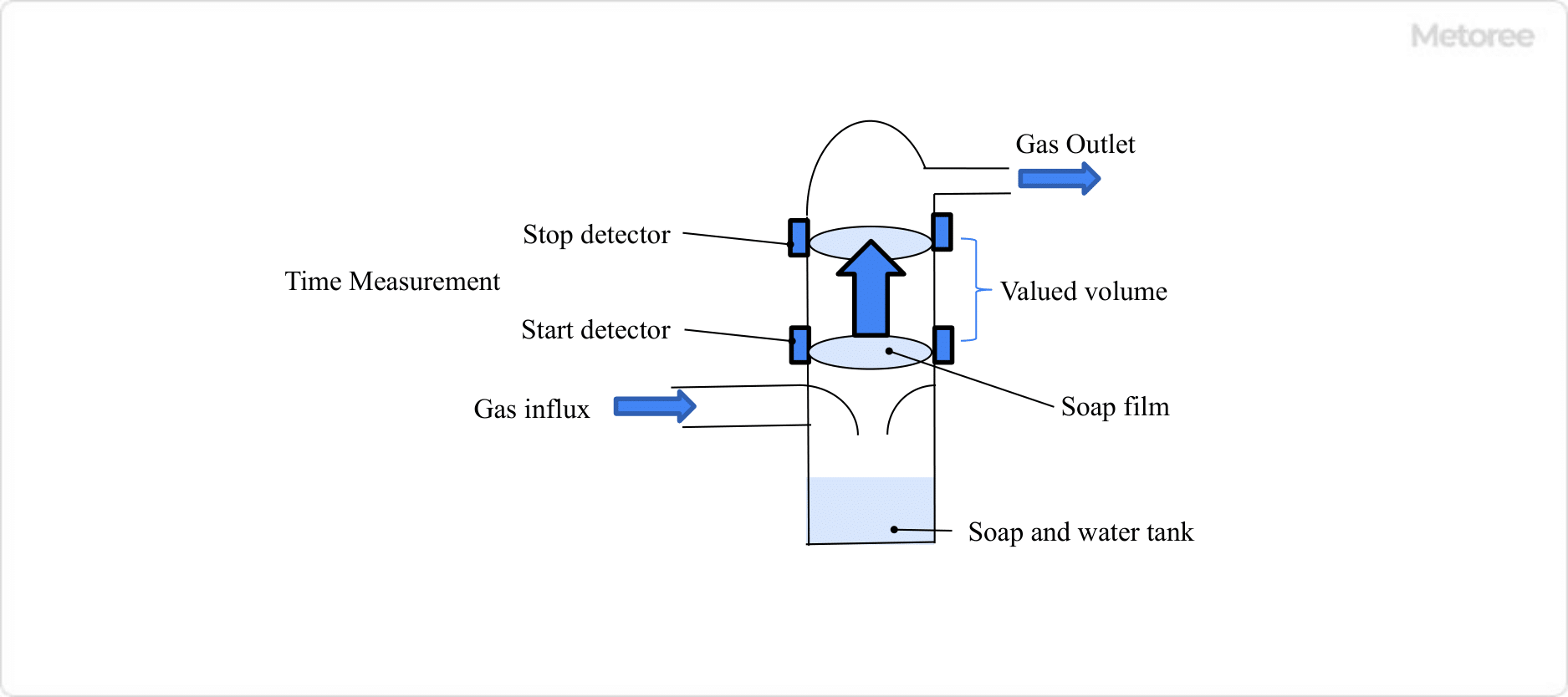

Figure 2. Principle of soap film flowmeter

The soap film flowmeter forms a soap film on the inside surface of a glass tube inside the instrument. By spraying the gas to be measured onto the soap film inside the glass capillary, the film is moved by the velocity of the gas. Since the glass capillary has a known volume, it is possible to calculate the flow rate of the gas to be measured, including the atmospheric pressure and temperature at that time, by measuring the travel time of the soap film with a detector.

However, the disadvantage is that the soap film flowmeter can measure only the length of the glass tube, so continuous measurement is not possible, and since a soap film is used for measurement, it is difficult to measure large flow rates that may cause the soap film to break. This is a disadvantage.

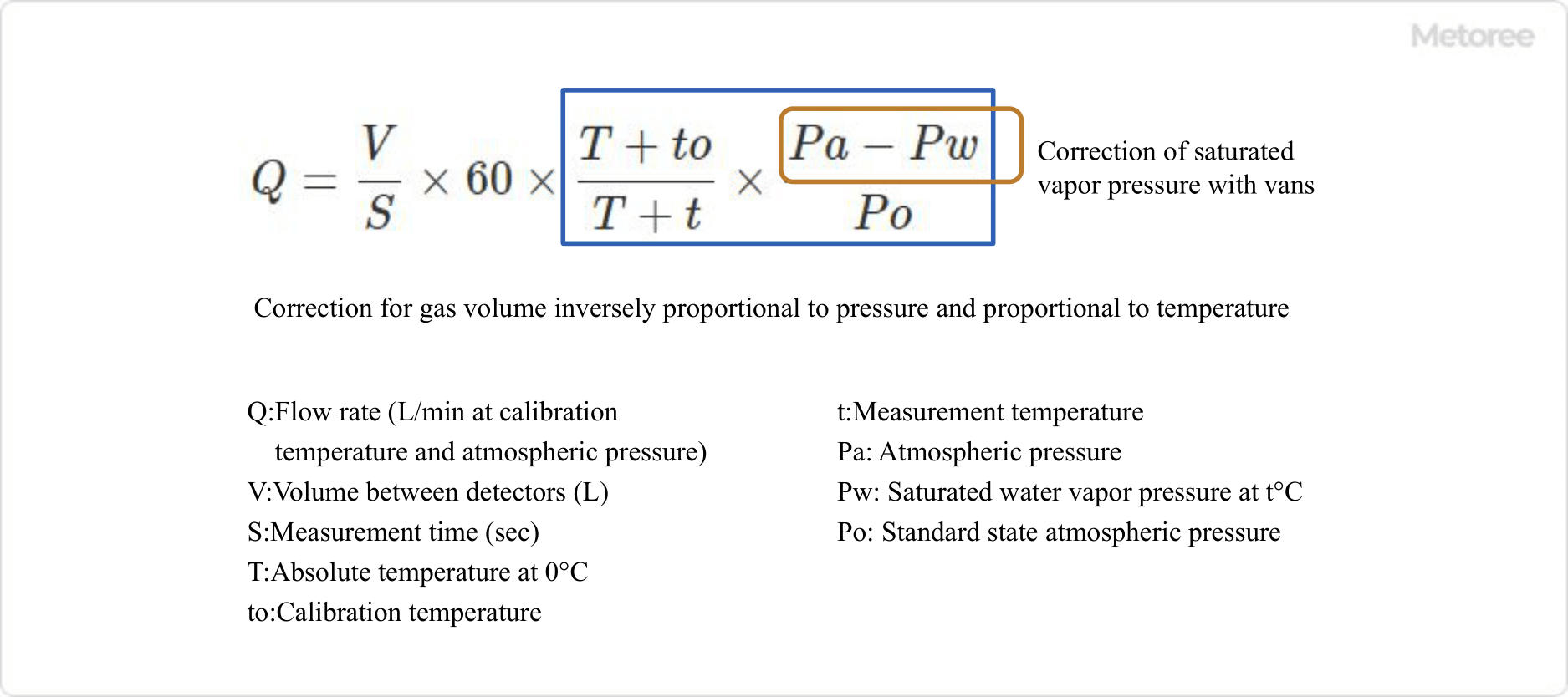

Figure 3. Corrections for atmospheric pressure and temperature

The necessary precautions when using a soap film flowmeter are that the use of a soap film may cause problems such as volume changes due to wetting of the gas from the point of use of the soap film, or permeation through the soap film of some gases. Particular attention should be paid to light gases, such as hydrogen gas. In addition, for precise measurement, atmospheric pressure correction and water vapor pressure correction must be performed.

More Soap Film Flowmeter Information

1. Maintenance of Soap Film Flowmeter

Soap film flowmeters require little maintenance compared to other flowmeters, but simple maintenance tasks do occur.

Soap Solution Refill

Since the liquid that creates the soap film gradually runs out, it is necessary to check the amount of liquid and replenish it. Replenishment fluid is sold by various manufacturers.

Glass Tube Cleaning

Glass tubes become gradually contaminated by airborne debris and require periodic cleaning.

- Drain all soap solution.

- Connect a vinyl tube longer than the glass capillary to the gas inlet.

- Inject water through the vinyl tube to fill the glass capillary.

- Leave for a while, then drain the water.

- Refill with soap solution.

In addition, the air pump may need to be replaced every few years for manual types and the pulse motor for electric types.

2. How to Use Soap Film Flowmeter

The procedure may vary slightly from manufacturer to manufacturer, but is generally as follows:

- First do the plumbing, wiring and setup.

- Moisten with soap solution.

- Set temperature, atmospheric pressure, etc., and calibrate.

- Start measurement.

If the inside of the glass capillary is not moistened, the soap film will disappear even if it is created. Wetting can be done directly with soap solution in manual meters, or by repeated soap film generation in automated meters.

These flow meters are highly convenient because they can be used easily whenever you want to use them. Read each manufacturer’s instructions for detailed procedures.