What Is a Transport Robot?

A transport robot is an industrial robot that is installed between assembly and processing machines to switch between processes automatically.

A transport robot is an industrial robot that is installed between assembly and processing machines to switch between processes automatically.

There are various types of transfer robots, from those that use sensors to set the position to be moved to those that use image recognition to automatically determine the transfer destination. Specifically, there are sliders suitable for simple applications, SCARA robots that are effective in EMS applications, and autonomous robots that can move freely within a factory.

Uses of Transport Robots

1. Slider

Sliders are characterized by their ability to move in only two directions (one axis). Servo motors or stepping motors are used as motors.

The simplicity of the mechanism makes it possible to use sliders at low cost. They are also used for transporting heavy objects and loading/unloading trucks.

2. SCARA Robot

SCARA robots are articulated robots that specialize in horizontal movement. It plays the role of grabbing a workpiece that has been conveyed from a conveyor and moving it to a conveyor next to it, or placing it in a container.

The advantage of these robots is that they can be operated in a small space, and in addition to transport robots, they are also used for assembling workpieces and tightening screws.

3. Autonomous Robots

Autonomous robots specialize in moving workpieces to remote locations within a factory. They are also called “AMR,” an abbreviation for “autonomous mobile robot.”

The unique feature of this system is that humans and robots can work together to perform transport tasks. An example of an application would be in a warehouse, where a person takes items from a rack and an autonomous robot transports the items.

The advantages of introducing autonomous robots include reductions in worker travel distance and manpower.

Principle of Transport Robots

When a transport robot recognizes a workpiece and moves it, the XYZ coordinates can be set in advance to allow the robot to operate. Another method that has recently become mainstream is coordinate recognition using image recognition.

The system takes pictures from the top and determines the space. The system then automatically determines where the cargo should be loaded and loads it. The advantage is that the coordinates do not need to be set in advance, but the disadvantage is that the cost is somewhat high.

Composition of a Transport Robot

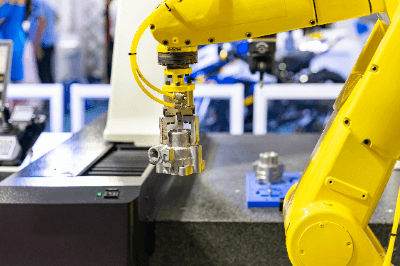

A typical robot consists of six axes. The reason for this is that when the position and posture of an object is expressed in a Cartesian coordinate system in three-dimensional space, there are six degrees of freedom: one degree of freedom in each of the XYZ axes and one degree of freedom in each of the directions around the XYZ axes. The fact that the robot has 6 degrees of freedom enables it to work in three dimensions while controlling its position and posture.

An industrial robot consists of a manipulator that performs operations, a controller that moves and controls the manipulator, and a programming pendant that teaches the manipulator how to operate. Basically, these are the three elements.

The six axes of the manipulator are generally controlled by AC servo motors. Each of the six is divided into the following six categories: body turning, lower arm to move the body back and forth, upper arm to move the arm up and down, wrist turning to rotate the arm, and wrist rotation to rotate the wrist.

Types of Transport Robots

There are several types of Transport Robots. The following are typical examples of Transport Robots.

1. AGV

AGVs are small, unmanned vehicles that operate automatically. They use sensors and control systems to detect their surroundings and move autonomously to their destination. They come in a variety of forms and are used to transport loads or pallets.

AGVs do not have operators. They are designed to transport goods, such as luggage, and are not supposed to be used on roads as defined by the Road Transport Law.

Meanwhile, AI and data analysis technologies have advanced in recent years. Increasingly, there are types of AGVs that can determine their own travel routes and travel autonomously without magnetic tape attached to the floor.

2. AMR

AMR is a robot that moves autonomously and is aware of its surroundings; it is equipped with sensors and cameras and uses SLAM technology and artificial intelligence to estimate and map its own location. It is used in warehouses and factories for picking, transporting, and inventorying goods.

AMR is autonomous and flexible, making it ideal for complex environments and tasks. They may travel the shortest route other than the predefined route. AGVs, on the other hand, follow a predefined route and are suitable for simpler hauling tasks.

3. Drones

An unmanned aerial vehicle that flies through the air to transport packages and goods. Currently, they are widely used for surveys of high places. In recent years, its use in the delivery industry has been attracting attention.

Other Information on Transport Robots

1. Size of the Transport Robot Market

The market size of transport robots is on the rise. Currently, the main applications are for use in hospitals, catering in restaurants, and warehouse goods transportation. Companies are beginning to use transport robots after weighing the cost of introducing robots against the cost of labor.

2. Challenges of Transport Robots

Although transport robots are expected to solve labor shortages, there are some challenges. The biggest issue is the cost of introducing them. Currently, transport robots are used only in fields where they are large or where high sales can be expected.

Many companies have not adopted them because of the high costs involved in their introduction. Operational stability is also an issue. If there are unplanned obstacles in the route or unexpected events, the system will not work. The current situation makes it difficult to introduce the system at critical sites where transport is a must.

However, in recent years, transport robots that can automatically avoid obstacles or automatically respond to irregularities by introducing AI have been introduced.

3. Use of Transport Robots in Hospitals

Transport robots are also expected to be used in hospitals. Since the medical field is chronically understaffed, there is a need to reduce manpower by introducing robots. Transport robots can take the place of staff in transporting medicines and specimens.

In addition, sensors can be installed on transport robots to determine the optimal route for their patrol. Currently, technologies such as automatic boarding and disembarking of elevators have also been realized.

It also has a display for presenting information to the patient and can communicate with the patient.