What Is a Square Shim?

A square shim plate is a type of shim plate with a rectangular (square) outside shape.

A shim plate is a component that is inserted between components or between components and equipment or locations to adjust the position, level, and spacing between them. Square shims are mainly classified as base shims and are used to correct and adjust the level and gap misalignment between parts during the assembly of machine components.

This adjustment reduces machine vibration and noise, prevents machine damage, and ensures stable operation.

In addition to square shims, shim plates include shim rings used for bearings and flanges, and shim tapes that can be cut to any length.

Uses of Square Shims

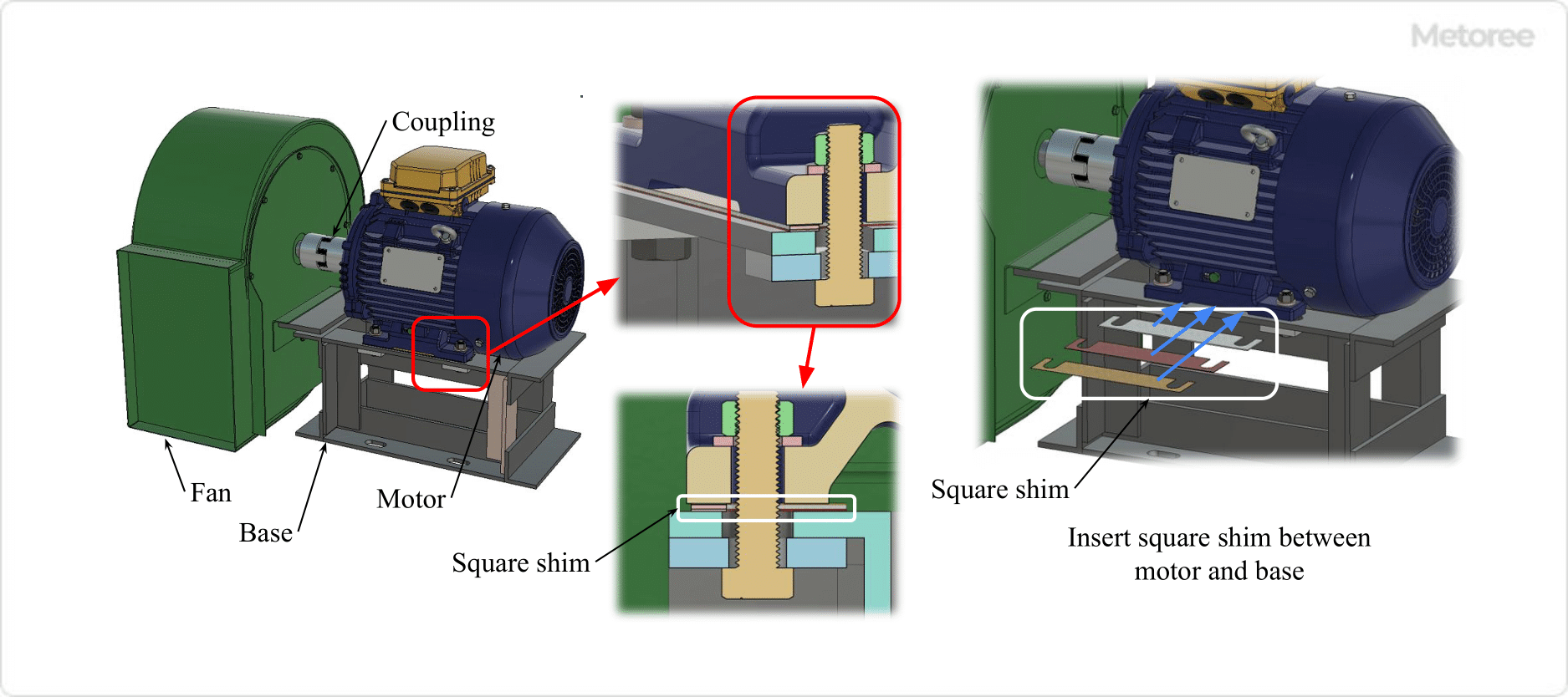

Figure 1. Example of square shim use

Square shims are often used as base shims for fine adjustment of levels between parts. Square shims are available in various thicknesses, for example, t0.05 to t1.0 mm for the same shape, and are adjusted to meet the required accuracy by combining one or more shims.

Square shims, in particular, are prepared in standardized dimensions in terms of size, thickness, and with or without drilling, making it easy to select the dimensions that fit. Therefore, they are used to adjust the level of general-purpose pump motors, pillow blocks, etc., and to adjust the inclination of equipment and facilities that require accurate leveling.

In the above example, a motor is used as a drive for a centrifugal fan. Angular shims (shims for the base) are inserted between the base on which the motor is installed and the motor mounting legs to adjust the tilt and level of the motor. As a result, the center of the motor output shaft – coupling – fan shaft is straight and accurate rotation is possible without vibration.

Spacers are also used to adjust gaps and spacing, but they are primarily used for adjusting the position of parts, not for adjusting the tilt and level. Liners are also used for the same purpose as shims, but with a thickness of t1.0 mm or more.

Principle of Square Shims

When high precision is required, simple installation of parts may not be enough to achieve the required accuracy. However, when the number of parts is large, it is not uncommon for the tolerance to accumulate and not be within the required accuracy after the entire assembly is completed.

Therefore, shim plates such as square shims are used for fine adjustment to ensure the required accuracy. The accuracy of the overall assembly is adjusted by inserting square shims between parts to change the tilt of the parts and the level of the parts.

The thickness of the square shim itself also requires accuracy and has a tolerance. It is important to check the thickness accuracy of the square shim to ensure that it meets the required accuracy. For the thickness accuracy, please refer to the dimensional table of each manufacturer.

Types of Corner Shims

1. Shape

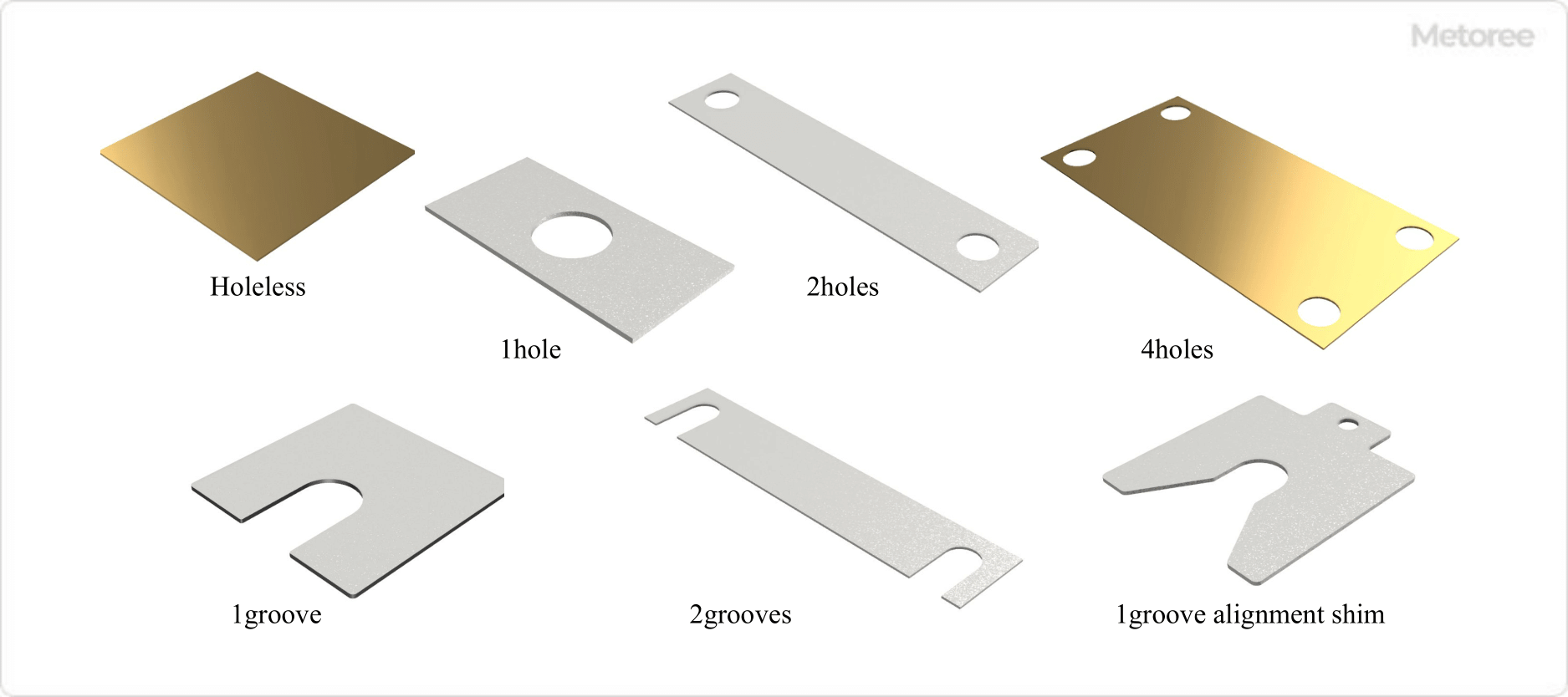

Figure 2. Example of square shim geometry

The main types of corner shim shapes are as follows:

- Without mounting holes

- With mounting holes (1, 2, 4 holes, etc.)

- With mounting grooves (1, 2 groove, etc.)

- Alignment Shims

Mounting holes and slots are mainly used for machines and equipment that are mounted and assembled with bolts. Slotted mounting holes allow insertion of bolts without completely removing them.

Alignment shims also have a portion to hook a tool or other object to facilitate insertion and withdrawal operations.

2. Material

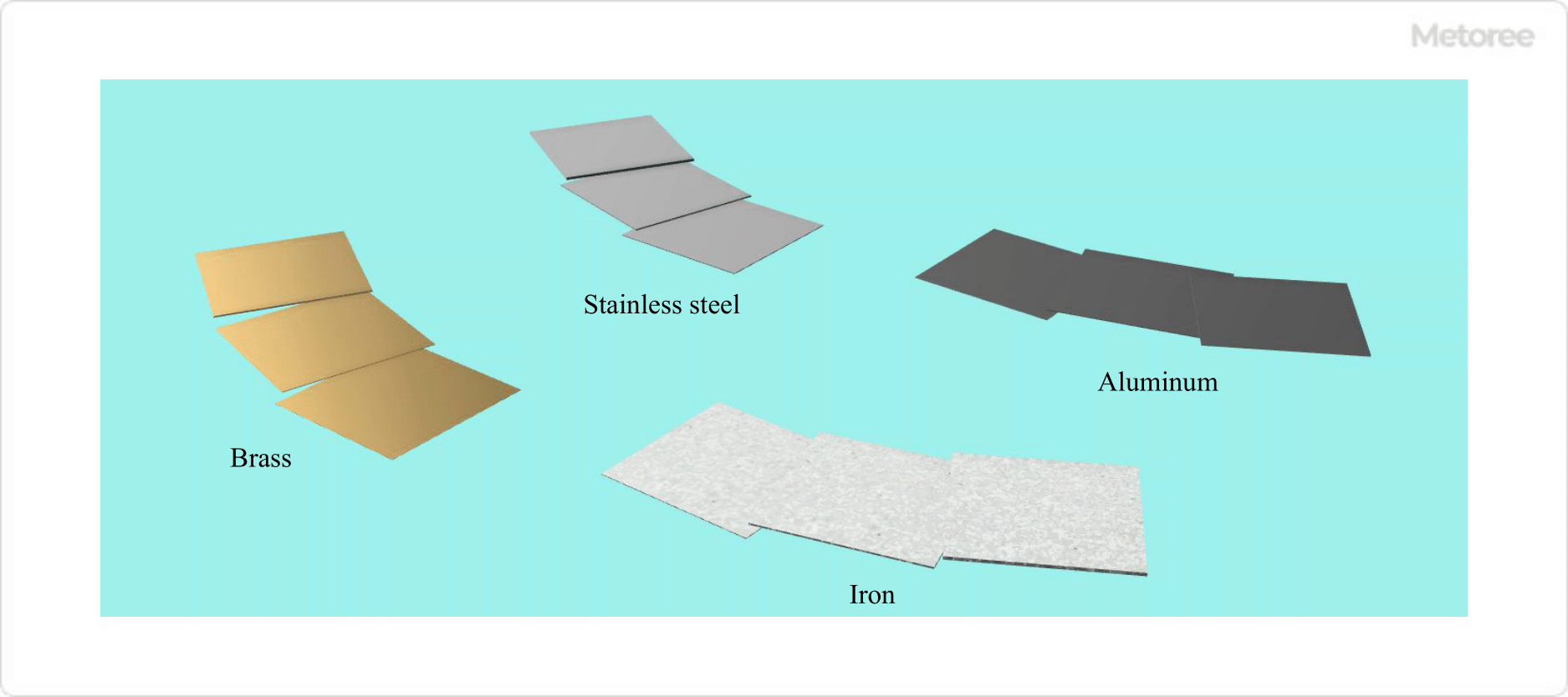

Figure 3. Material example of square shim

The following are the main types of materials used for square shims. For the selection of materials for square shims, stainless steel or aluminum is used if the environment in which they will be used, such as corrosion resistance.

- Brass

Brass C2680, C2681, etc. - Iron

Cold-rolled steel sheet and strip SPCC, etc. - Stainless Steel

Cold-rolled stainless steel sheet SUS304, SUS316, etc. - Aluminum (Al)

Aluminum and aluminum alloy sheets and strips A1050

3. Other

Other types of angular shims include:

- Surface Treatment

Treated with black dye to prevent rust. - Adhesive Application

Adhesive is applied to the surface for temporary fixing. - Laminate Type

Several ultra-thin shim plates (e.g., t0.05 mm) are pre-bonded, and the thickness can be fine-tuned by peeling off one to several shim plates at a time. - Marking

The surface is engraved and ink-marked with values such as plate thickness.