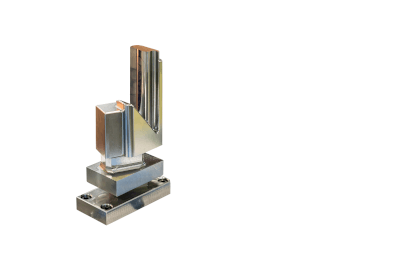

What Is a Slide Core Unit?

A slide core unit is a mold component primarily used in resin molding. It’s a movable part within a mold, facilitating the production of products with undercuts or complex inner geometries in a single molding process. Although integrating a slide core unit mechanism allows for intricate shapes in one go, it’s important to note the potential increase in tooling costs and design issues due to more detailed molds and additional parting lines.

Applications of Slide Core Units

Slide core units are essential for creating undercut areas in plastic molded products, which are shapes that obstruct the normal path of demolding. These units enable the forming of such areas, allowing for the product’s removal in one molding cycle. While a simple cup can be de-molded with a standard mold, a cup with a handle necessitates a slide core unit due to the undercut. This technology is also pivotal in producing complex plastic items like construction window frames, door handles, and electronic device housings.

To mitigate undercut challenges in complex parts, it’s often advisable to segment the part into manageable sections.

Principle of Slide Core Unit

The slide core unit employs a mechanism, often using pins or cam blocks, to de-mold products with undercuts by moving specific mold parts. This automatic opening and closing action, perpendicular to the mold’s opening, enables diverse shape creation. However, this complexity can lead to increased mold costs and reduced durability and maintenance ease compared to traditional molds. Design strategies often include reducing undercuts through part segmentation to manage costs effectively.

Types of Slide Core Units

There are various slide core units, distinguished by their movement mechanisms:

1. Slide Core Unit Method

Using an angular pin, this method involves a fixed angular contact and a movable slide core unit, noted for its simplicity and reliability.

2. Inclined Slide System

Featuring an inclined slide connected to a slide unit via a rod through the movable die’s inclined hole, this system activates upon ejection, moving the slide unit into the product.

3. Hydraulically Driven Slide System

This method uses a hydraulic cylinder, suitable for parts that are challenging to drive with angular pins, allowing independent slide movement or large unit handling.

Other Information on Slide Core Units

Utilization of Slide Core Units

Slide core units offer versatility in mold design, enabling the change of only the undercut shape within the same mold. This approach allows for varied product designs using a single mold. However, the complexity and number of molds can increase costs, maintenance challenges, and the occurrence of parting lines and burrs.