What Is a Stamping Die?

A stamping die is a tool used in the stamping process to shape products.

A stamping die is a tool used in the stamping process to shape products.

It comprises a pair of upper and lower dies designed to interlock. When combined, these dies form the desired shape. Set in a stamping press, the dies apply pressure to the metal being processed, causing plastic deformation and shaping the metal.

There are two main types of stamping dies: dies, which press flat metal sheets between upper and lower dies, and molds, used for casting and plastic molding, where molten material is poured into the die.

The type of press machine used can vary, with some being manually operated and others capable of automated, complex shape formation using multiple dies.

Stamping dies enable bending, shearing, and drawing – key processes in metal product fabrication. Specific dies like bending dies, shearing dies, and drawing dies are used for these respective processes.

Uses of Stamping Dies

Stamping dies are vital in manufacturing various products due to their ability to mass-produce identical shapes quickly. They are commonly used in making parts for automobiles, motorcycles, medical equipment, and construction materials, all requiring precision and efficiency in their production.

Different stamping dies are designed for various processes like shearing and bending.

The press machine’s pressure is crucial in stamping, where the die is pressed against the metal to induce plastic deformation. Note that while higher press performance facilitates easier forming, it also increases press forming efficiency and operational electricity costs.

Principle of Stamping Dies

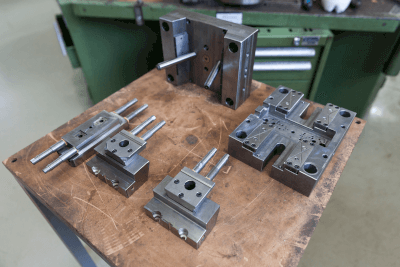

Stamping dies are manufactured using machining centers, where the desired shape is cut and heat-treated. Die fabrication typically takes 3 to 6 months, depending on the product’s size and complexity.

Materials like alloy tool steel, known for its toughness, and high-speed tool steel, recognized for heat and wear resistance, are used for stamping dies due to the high pressure involved.

Stamping dies can be broadly categorized into two types based on their operation during stamping. However, it’s important to note that the definitions of these categories can vary.

1. Die

Dies are primarily used for processing metal sheets. In these dies, the metal is placed between the open upper and lower dies, and then the upper die is pressed into the lower one to form the shape.

2. Mold

Molds are mainly used for processing plastics. Molten resin is poured into the closed upper and lower molds, and then allowed to cool and harden before the formed product is removed.

Types of Stamping Dies

Stamping dies come in three main types:

1. Single-Shot Mold

A single-shot mold performs one type of stamping process continuously. It’s the most common among the three types and can handle one to several stamping processes. Its simplicity makes it cost-effective, though it is less efficient due to manual operation.

2. Progressive Die

A progressive die houses multiple stamping processes within a single die. It automatically transfers metal to the next process, enabling efficient, high-precision production. Though complex and costly to produce, it’s the fastest among the three types and accommodates complex shapes.

3. Transfer Die

A transfer die links single-shot dies for each process via a transfer mechanism. It combines the large processing capability of single-shot molds with the automation of progressive molds. While production costs are higher and processing time slower than progressive dies, it offers high versatility.