What Is a Wire Processing Service?

A wire processing service is a method where long, thin metal materials are formed into desired shapes using techniques like bending, cutting, welding, and forging. Forming machines and coiling machines are commonly used, with press machines for more complex shapes.

Uses of Wire Processing Services

Wire processing services are not just limited to bending. They can produce various products, including welded wire meshes and threaded wire tips. Typical products include wire, screws, wire mesh, springs, and wire rope. This service is essential in creating diverse items like car seat springs, clothes hangers, protective netting, and fryer baskets.

Principle of Wire Processing Services

Wire processing relies on the metal’s plasticity, primarily forming shapes through bending, combined with welding and crushing. Less cutting means reduced material waste, although this method is less precise than cutting.

1. Bending

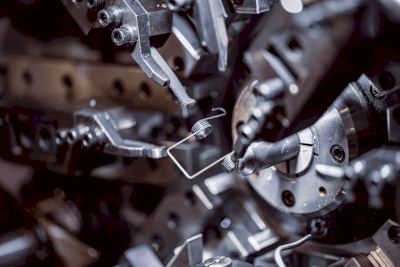

NC forming machines enable complex bends and cuts, ideal for spring shapes and mass production without the need for dies. Coiling machines are also used for quick and simple spring shapes.

2. Welding Process

Spot welding is primarily used for joining materials, while butt welding joins wire rod ends.

3. Press Working

When NC machines are not suitable, benders, manual bending machines, or press machines are used, especially for small-lot production. Press machines enable mass production with fabricated dies.

Post-processing includes surface treatments like painting, plating, and vinyl or nylon coating to prevent oxidation.