What Is Shearing Machinery?

Shearing machinery is a machine used to cut metal sheets into straight lines by shearing.

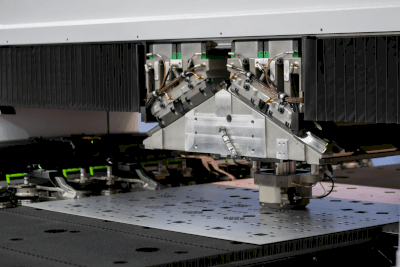

Shearing machinery is equipped with an upper blade and a lower blade.

Shearing is performed by mechanically applying pressure from above and below to the metal plate to be cut. Shearing machinery can be powered by either a mechanical or hydraulic source, which should be selected based on cost and maintenance requirements.

In recent years, turret punch press processing and laser processing have become more common, and the demand for shearing machinery is decreasing.

Uses of Shearing Machinery

Shearing machinery is used in sheet metal processing plants for cutting sheet metal. Depending on the model, some Shearing Machinery can cut even metal sheets as long as several meters. However, due to the limitation of the blade length, the cutting length is limited to about 6 meters.

Shearing machinery can be used to cut plates of materials such as stainless steel and steel sheets with metal sheets that fit within this size. For cutting longer metal sheets that cannot be handled by Shearing Machinery, laser cutting machines are generally used.

Principle of Shearing Machinery

Shearing machinery is similar to the principle of cutting paper with scissors that we use in our daily lives. The metal sheet to be cut is positioned where the blade of the Shearing Machinery will strike it, and then the upper blade descends to cut the sheet.

Shearing machinery can be classified into mechanical and hydraulic types, depending on the blade drive system.

1. Mechanical Type

In the case of the mechanical type, the blade is driven by a motor and clutch, and is characterized by its high cutting speed. Compared to the hydraulic type described below, the mechanical type is inexpensive, and since it does not use oil, maintenance is relatively simple.

2. Hydraulic Type

The hydraulic type uses hydraulic pressure generated in the cylinder to drive the blade powerfully, resulting in high cutting performance. It can cut even relatively thick metal plates, which is difficult with the mechanical type. On the other hand, care must be taken to avoid problems such as oil leakage.

Other Information on Shearing Machinery

Points to Keep In Mind When Using Shearing Machinery

There are several points to keep in mind when using Shearing Machinery to produce high-quality products and to work safely.

Specific Usage

1. Adjusting the Clearance

Clearance in shearing machinery is the distance between the upper and lower blades. Even with scissors that we use in our daily life, paper cannot be cut well with scissors that have a large gap between the two blades.

For the same reason, in shearing machinery, the clearance between the upper and lower blades is important, and the size of the clearance makes a difference in the quality of the cut surface. If the clearance is too narrow, the load on the blade is too great and the blade wears easily, shortening the life of the blade.

Conversely, if the clearance is too large, the cut surface will have sagging and burrs. The appropriate clearance is determined by the material to be cut and the plate thickness, but in general, the appropriate clearance is approximately 6~10% of the plate thickness.

2. Adjustment of Shear Angle

The shear angle is the opening angle between the upper and lower blades, just like the angle between two blades when scissors are opened. When the shear angle is large, or in scissors, when the scissors are wide open at the beginning of a cut, a small amount of force can be used to cut.

However, if the shear angle is too large, the cut material is prone to deflection (bow), twist (twist), and warp (camber).

3. Do Not Cut Materials Over the Maximum Thickness

Shearing machinery has a maximum thickness limit. Cutting material that exceeds the maximum thickness will put a heavy load on the shearing machine, and in the worst case, may result in a breakdown.

When handling a shearing machine, you should check the maximum plate thickness and be careful not to cut any material that is thicker than the machine is capable of cutting.