What Is Stainless Steel?

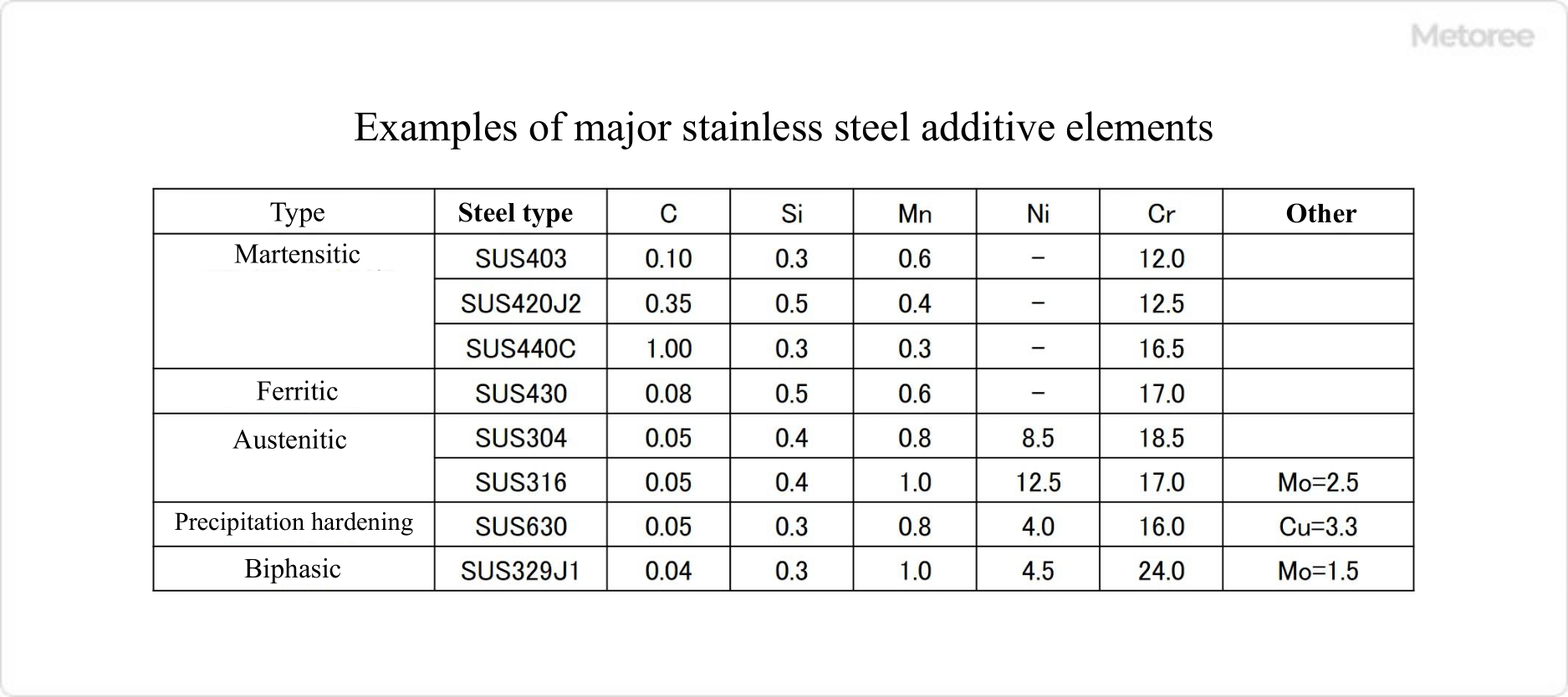

Stainless steel is an alloy steel that contains more than 50% iron (Fe), less than 1.2% carbon (C), and more than 10.5% chromium (Cr) as its main constituent.

It is well known for its excellent corrosion resistance and rust resistance. It also has excellent properties in terms of heat resistance, workability, and strength. The name “stainless steel” derives from “stain” (rust) and “less”.

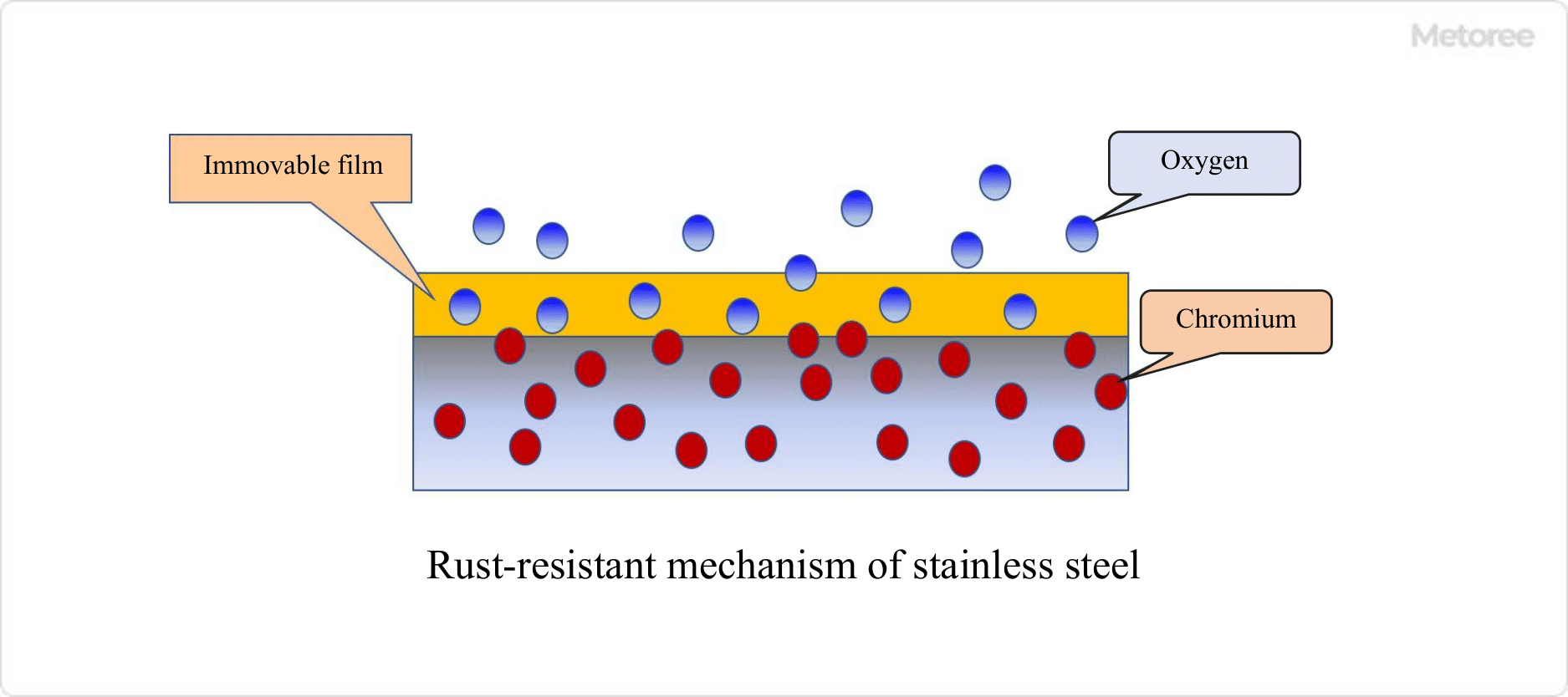

Stainless steel is rust-resistant due to the formation of a thin film, known as a passive film, on its surface. Generally, when iron combines with oxygen, it becomes iron oxide and rust occurs. Chromium, however, binds to oxygen more easily than iron, and when chromium oxidizes before iron does, it forms a passive film that covers the steel surface and inhibits rust formation.

This property of chromium makes stainless steel resistant to rust. Adding nickel to stainless steel further increases its corrosion resistance, making it possible to obtain a stainless steel that is even more resistant to rust. However, even stainless steel can rust. Specifically, this is the case where the metal has been in contact with rusted metal for a long period of time or has been scratched.

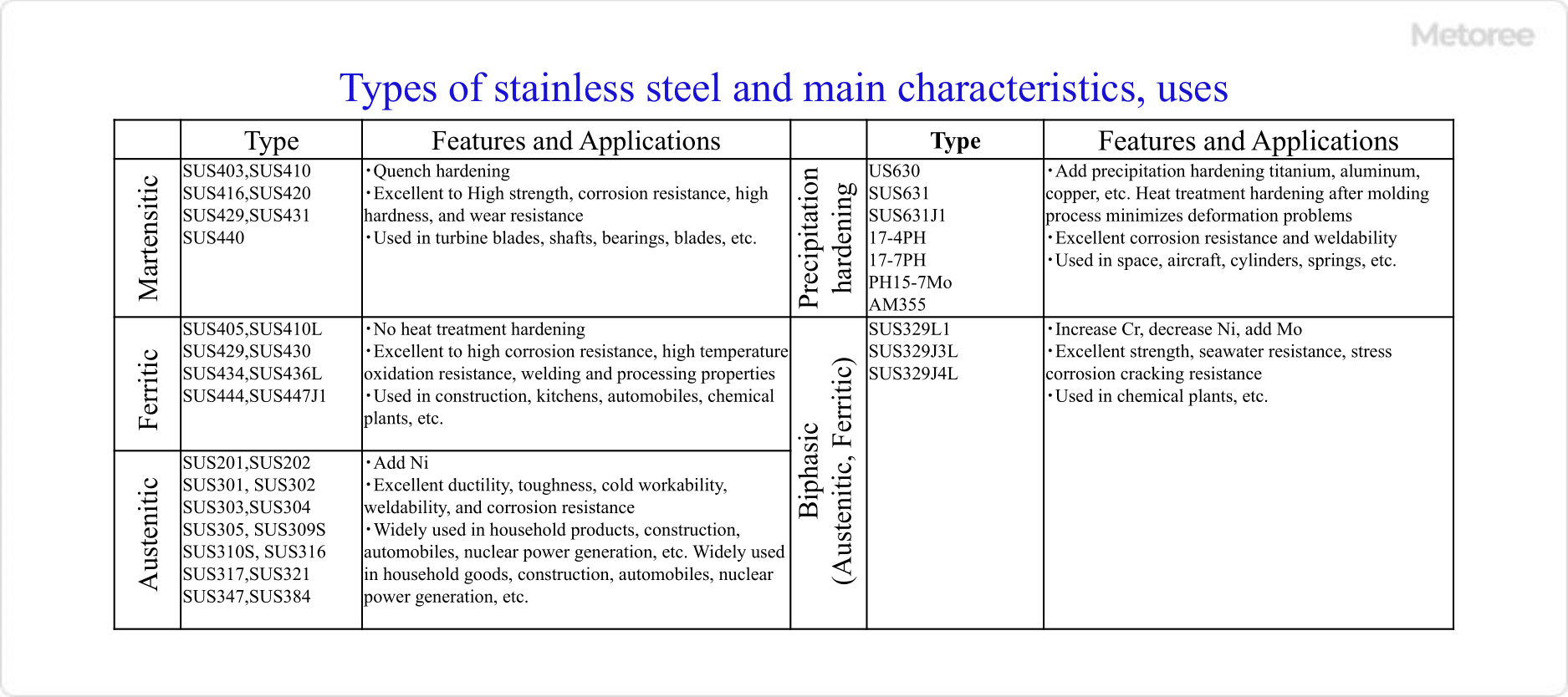

The type of stainless steel is indicated by “SUS + number” as in “SUS304” or “SUS430.” SUS is an acronym for “steel use stainless,” and the number following it is the grade of stainless steel. SUS304″ is a stainless steel used worldwide.

Uses of Stainless Steel

Stainless steel is used in a wide variety of fields, taking advantage of its excellent corrosion resistance. In precision equipment, home appliances, and industrial equipment, it is often used as exterior covers and mechanical parts.

The reasons include the fact that a clean appearance can be obtained without surface treatment, and because plating or painting is not required for dual rust-preventive purposes. Also, the lead time for parts is short, and under certain conditions, the use of stainless steel may be less expensive than the use of ordinary steel.

Another advantage is its excellent heat resistance and heat retention properties due to its low thermal conductivity. At home, stainless steel is used for spoons, forks, and kitchen sinks. In addition, due to its high strength and hardness, stainless steel is sometimes used as a roofing material for large facilities such as dome stadiums, and for parts that play an important role, such as turbine blades and brake discs used in jet aircraft.

Characteristics of Stainless Steel

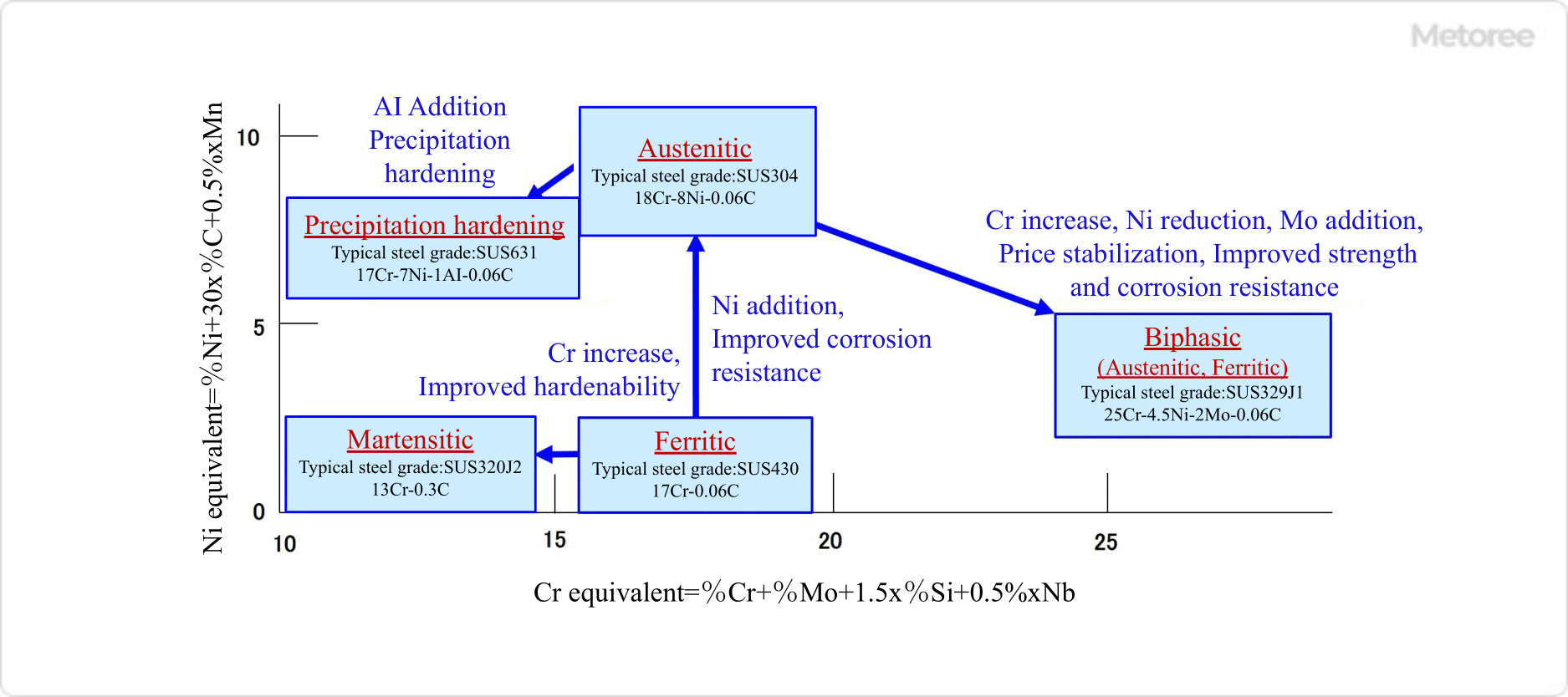

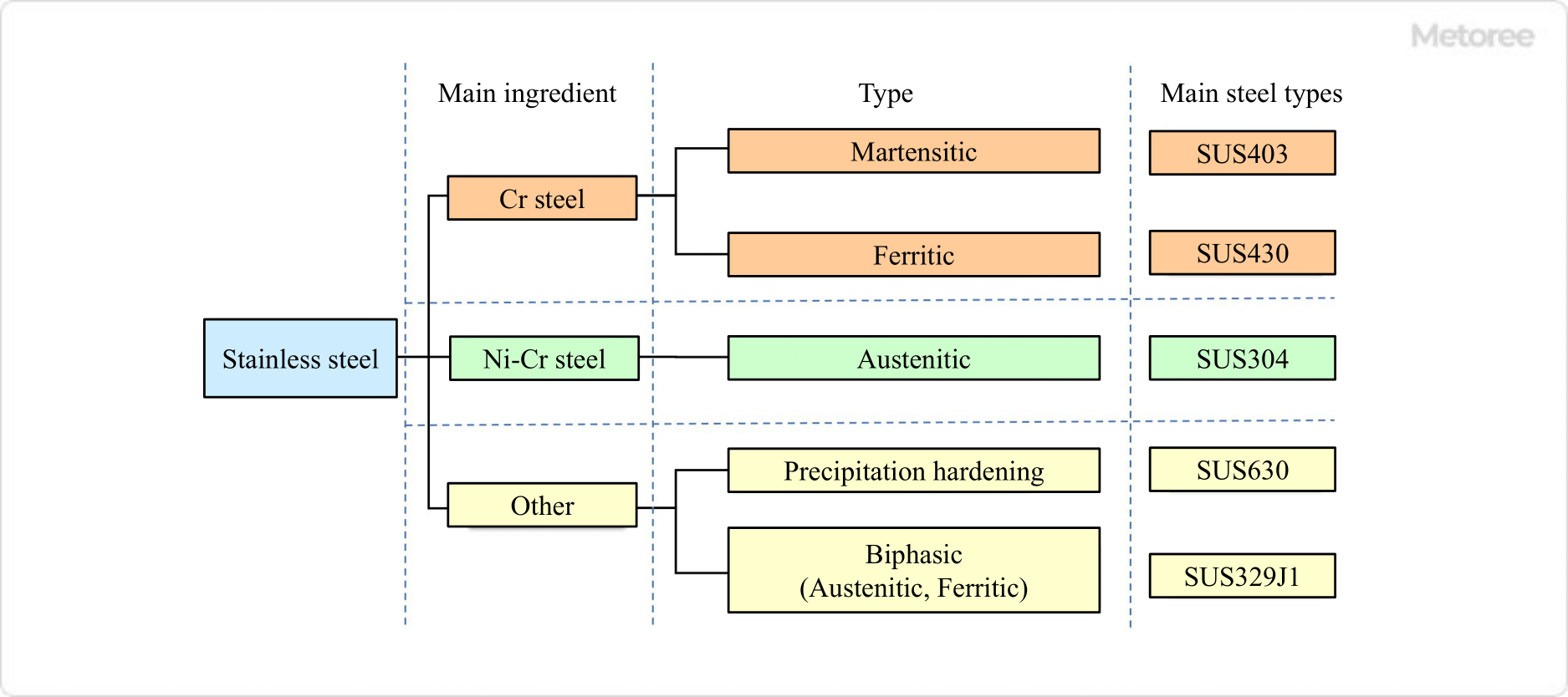

It has very high corrosion resistance and can be classified into five types according to alloy ratios and other factors, each with different characteristics.

Types of Stainless Steel

1. Martensitic Type

Martensitic stainless steel is composed mainly of chromium and carbon and does not contain nickel. It has high hardness due to the formation of a hard metallic structure called martensite by heat treatment. However, it is more susceptible to rust and has the lowest corrosion resistance in harsh environments compared to other types of stainless steel.

Like ordinary steel, it is characterized by its magnetic properties (magnets stick to it). The main applications of martensitic stainless steel include blades, nozzles, turbine blades, and disc brakes.

2. Ferritic Stainless Steel

Ferritic stainless steel is mainly composed of chromium and does not contain nickel. After austenitic stainless steel, ferritic stainless steel has excellent corrosion resistance and is suitable for press work because it remains soft with little hardening after heat treatment.

Its main applications include building interior materials and gas and electric appliance parts. Another characteristic of ferritic stainless steel, such as SUS430, is its magnetic properties.

3. Austenitic Stainless Steel

Austenitic stainless steel is composed mainly of chromium and nickel and forms a metallic structure called austenite at room temperature. It has excellent corrosion resistance, heat resistance, and weldability, and is used in various fields, including household items such as spoons and forks, automotive parts, and construction supplies.

4. Precipitation Hardening Type

Precipitation hardening type stainless steel is composed mainly of chromium and nickel, to which elements such as aluminum and copper are added. They are then subjected to a precipitation hardening treatment, a heat treatment similar to quenching and tempering, to improve hardness by utilizing precipitation of intermetallic compounds of these elements. Although not as resistant to corrosion as austenitic stainless steel, it is superior to ferritic stainless steel.

SUS630 is a precipitation hardening stainless steel.

5. Duplex Stainless Steel

Duplex stainless steel is a mixture of austenitic and ferritic stainless steel. A typical example is SUS329J1.