What Is an Electromagnetic Brake?

An electromagnetic brake is a device that applies a brake using electromagnetic force.

An electromagnetic brake is designed to apply the brakes in the event of power loss. Therefore, they are used when it is necessary to apply the brakes on the spur of the moment. They are primarily used in industrial applications and are not commonly found in homes.

Since electromagnets are used, electricity is used as the power source. As it is more cost-effective to use the same power source, they are mostly used to stop motors that are driven by the same electricity.

Uses of Electromagnetic Brakes

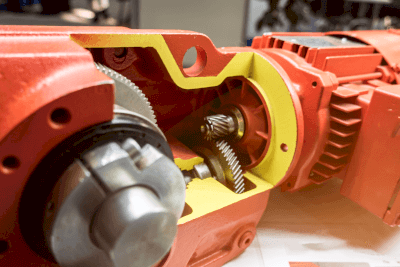

Electromagnetic brakes are almost never used in automobiles. They are basically used in motors with reduction gears.

A typical example is the hoisting equipment of a crane. If the brake is not applied when power is lost, the suspended load will fall, which is very dangerous. Therefore, electromagnetic brakes are used in crane hoisting equipment to stop the suspended load in an emergency.

Electromagnetic brakes are also sometimes used on conveyor belts and other equipment to prevent inertia-induced movement of workpieces when stopped.

Principle of Electromagnetic Brakes

Electromagnetic brakes are mainly divided into three parts: the electromagnet part, the rotor part, and the brake part.

The electromagnet part is responsible for the electrical circuit that controls the operation of the electromagnetic brakes. A coil wound around an iron core generates a magnetic field like a magnet when electricity is applied to the coil. This is called an electromagnet. The electromagnets in electromagnetic brakes attract the rotor by magnetic force, thereby controlling the motion of the brake.

The rotor part moves in the same way as the rotating shaft. When the brake is not applied, the rotor rotates in the same manner as the rotating shaft, and when the brake is applied, it makes contact with the brake by spring force. Friction between the brake and the rotor causes the rotating body to come to a sudden standstill, thereby applying the brake.

The brake part refers to the contact surface that brings the rotor to a standstill. It is called a brake shoe or armchair. If the rotor is kept stationary continuously or rotated while rubbing against the rotor, it will heat up due to friction, causing failure such as burning out of the brake portion. Therefore, it is essential to adjust the distance to the rotor and the degree of contact.