What Is an Electromagnetic Chuck?

An electromagnetic chuck is a device that uses an electromagnet to clamp workpieces in machine tools.

Requiring an external power supply for operation, electromagnetic chucks generate heat when energized. They are best suited for machining large materials where high precision is not the primary concern. Their size can be easily adjusted to accommodate a wide range of material sizes.

The chucking force is adjustable via an external switch, simplifying the automation of the chucking process alongside machinery. A variant, the permanent electromagnetic chuck, utilizes a magnet that is energized only during attachment and detachment, conserving energy when not in use.

Applications of Electromagnetic Chucks

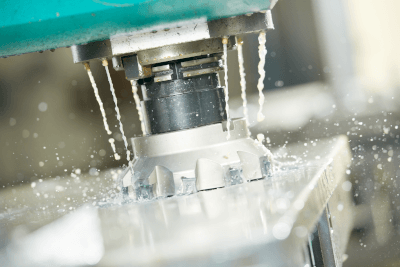

Electromagnetic chucks are integral to various machine tools, including milling machines, drilling machines, grinding machines, and more. They are invaluable for securely holding workpieces during both cutting and non-cutting processes, such as electrical discharge machining. Their ability to switch the magnetic force on and off facilitates easy handling of ferrous work materials.

Principle of Electromagnetic Chucks

1. General Electromagnetic Chuck

This type of chuck consists of an iron core and a coil, with a faceplate designed to prevent ingress of water. Energizing the electromagnet generates magnetic field lines that attract and hold the workpiece firmly. De-energizing the electromagnet releases the workpiece instantly.

2. Permanent Electromagnetic Chuck

Employing a permanent magnet, this chuck type is energized only during the attachment and detachment of materials, maintaining magnetic force without continuous power, thus being energy efficient. It features rod-shaped electrodes and brass separators for pulse voltage application, enabling high-precision machining without thermal displacement.

Features of Electromagnetic Chucks

1. Easy Attachment and Removal of Workpiece

The ability to switch the electromagnet on and off simplifies the process of attaching and detaching workpieces, facilitating automation.

2. Adjustable Suction Force

The chuck’s suction force is adjustable, making it versatile for different types and intensities of machining.

3. Easy to Enlarge Chuck Size

Electromagnetic chucks can be easily scaled up, with models available that offer clamping forces around 300 kg.

Types of Electromagnetic Chucks

Electromagnetic chucks come in round and square shapes, catering to various work materials and machining processes. They can be categorized by cooling method: non-cooled, water-cooled, and air-cooled, with cooling essential for maintaining workpiece temperature and machining accuracy. Tiltable models allow for precise angle adjustments, crucial for grinding mold parts, featuring high-precision components and temperature control to ensure accuracy.

The permanent electromagnetic chuck combines permanent magnets and electromagnets for energy-efficient operation during attachment and detachment processes.