What Is a Universal Tester?

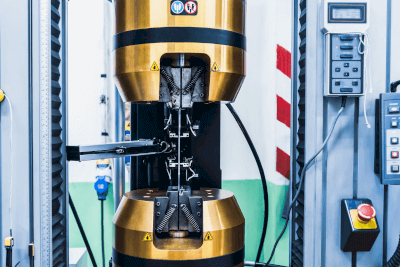

Universal testers are versatile instruments designed to measure the physical properties of various materials by applying stresses like tension, compression, and bending. They are fundamental in assessing materials such as plastics, metals, and composites for their strength and hardness.

Uses of Universal Testers

These testers are indispensable in material development, quality control, and safety assurance across industries. They adapt to different testing requirements by changing grips and jigs, making them valuable for heavy industry, construction, and evaluating packaging materials.

Principle of Universal Testers

Operating on Pascal’s principle, universal testers exert force on a specimen to elicit a stress-strain response, revealing material properties. The system comprises a movable crosshead and interchangeable jigs for applying various stress types.

Types of Universal Testers

Diverse in application, universal testers include models for specific industry needs—from compact designs for soft materials to large machines for evaluating construction materials.

Other Information on Universal Testers

1. Tensile Test

This test measures the elongation and breaking point of a material under tension, helping to determine its yield and rupture points.

2. Bending Test

Conducted by applying a bending force, this test helps understand material behavior under bending stress, utilizing either three-point or four-point bending methods.

3. Compression Test

This test assesses a material’s resistance to compression, often until the point of fracture. Non-contact sensors like CCD cameras are used (instead of contact-type sensors such as strain gages) to avoid damage to measuring equipment.