What Is a Sterilizer Accessory?

A sterilizer accessory is a device used to kill microorganisms attached to various products.

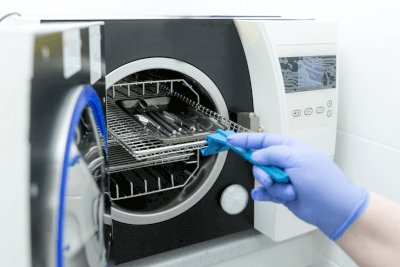

Sterilizers are widely used especially in the field where hygiene must be ensured. Typical examples include autoclaves that use steam at high temperatures and pressures, electric ovens that sterilize by drying at high temperatures, and gas sterilizers that use ethylene oxide gas. The optimal method is selected in consideration of the material to be sterilized, sterilization cost, and environmental impact.

Uses of Sterilizer Accessories

Sterilizer accessories are widely used in medical institutions and food manufacturing sites where hygiene must be ensured, and in research laboratories where accuracy must be maintained. The most suitable sterilization method is recommended by the manufacturer, depending on the level of sterilization required and the material to be sterilized.

Autoclave sterilization is often preferred in medical and research institutions due to its superiority in terms of running cost and time efficiency compared to other sterilization methods. Electric ovens, etc. are used next, mainly for glass and other materials that are resistant to high temperatures.

Ethylene oxide gas sterilizers and ultraviolet sterilizer accessories are used for plastic and rubber products with low heat resistance.

Principle of Sterilizer Accessories

Typical sterilizers include autoclaves and gas sterilizer accessories. Based on the principle of sterilizers, they can be used differently depending on the material to be sterilized.

1. Autoclave

In the autoclave, a typical sterilizer accessory, target materials are placed inside a pressure cooker-like sterilizer, which maintains an environment above atmospheric pressure for a certain period of time to produce steam at 2 atmospheres and a high temperature of about 130°C to sterilize the materials. Autoclaves are also called high-pressure steam sterilizers.

According to the European sterilization standard (EN13060), sterilizer accessories are classified into three levels of performance: Class B, Class S, and Class N. Which class of sterilization should be used depends on the target instrument.

- Class B

The highest level of sterilization is achieved. It can be used for all types of instruments, including solid, porous, hollow, and non-packaged instruments. - Class S

Sterilizable with manufacturer-specific products that can be sterilized in Class N. - Class N

Sterilizable for non-packaged solid instruments. After sterilization, they should not be stored and must be used as soon as possible. This is the most common type used in the majority of medical institutions.

When disinfection is performed by boiling with steam at 100°C under atmospheric pressure, some microorganisms such as Clostridium bacteria can survive. However, steam at 120°C has high thermal energy and accelerates hydrolysis reactions, which can kill these microorganisms. Sterilization is possible at lower temperatures than in electric ovens. It can be used for materials that are sensitive to high temperatures. Another advantage is that purified water is used, and only heat and steam are emitted, so there is little impact on the human body.

2. Gas Sterilizer Accessories

Gas sterilizer accessories are used for materials that are particularly sensitive to high temperatures. Instead of high temperatures, gas sterilizers utilize the high nucleophilic effect of ethylene oxide. When microorganisms are exposed to ethylene oxide, they cause an alkylation reaction in proteins and nucleic acids, which denatures and kills them.

Since ethylene oxide affects not only microorganisms but also the human body, it is necessary to control the work environment and select the equipment to be used. It is advisable to consider the target equipment in terms of sterilization level (Class B, S, N), size of the equipment to be sterilized, sterilization method, installation cost, installation location, and running cost.

Other Information on Sterilizer Accessories

Difference From Sterilization, Sanitization, and Disinfection

Sterilization is defined as the reduction of the probability of survival of all microorganisms, whether living pathogenic (including spores) or non-pathogenic, to less than one in a million.

Similar terms to sterilization include sterilization, sanitization, and disinfection.

- Sterilization

This term is widely used in the general sense of simply killing microorganisms. Furthermore, it is used when referring to objects such as equipment, while “sterilization” is also used for the microorganisms themselves. - Sterilization

Sterilization is the process of reducing the number of bacteria that can grow on an object by physical, chemical, or biological action. - Disinfection

Refers only to killing pathogenic bacteria that are harmful to humans or inactivating (killing) pathogens.

Each requires a different response, depending on the degree to which the bacteria are reduced.