What Is a Metal Nameplate?

A nameplate is a metal nameplate on which the company name, product name, serial number, etc. are engraved, unevenly processed, and written on a metal plate. It is used to describe the name, specifications, control number, etc. of the device and attach it to the product.

A nameplate is a metal nameplate on which the company name, product name, serial number, etc. are engraved, unevenly processed, and written on a metal plate. It is used to describe the name, specifications, control number, etc. of the device and attach it to the product.

Usage of Metal Nameplates

The purpose of metal nameplates is for the manufacturer of a product to attach product information to the product as a nameplate, and for the user of the product, it serves as an identification and recognition plate for the product in equipment management. Therefore, nameplates are used on all kinds of products, including all kinds of industrial, industrial, and household appliances.

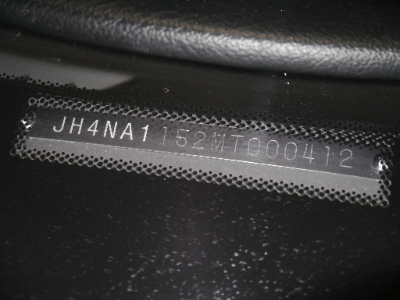

For example, on industrial equipment and machinery, “etched nameplates,” which are metal plates engraved with the name of the manufacturing company, equipment name, model, serial number, date of manufacture, etc., and dyed black for the engraved characters, are affixed to the equipment and machinery. On buildings and other architectural structures, the name of the building and date of completion are engraved, and on bridges and other civil engineering and architectural structures, the name of the bridge, name of the river, date of completion, etc., are engraved on metal nameplates with the engraved characters in black. Metal nameplates with the vehicle type, VIN number, and other information are also attached to the engine compartment of automobiles.

In addition, acrylic metal nameplates with the names of devices and operations engraved on them are often affixed to control devices and other equipment.

Features of Metal Nameplates

There are several types of metal nameplates, depending on the material of the plate and the method used to display and manufacture the letters.

The materials used for nameplates include metal, resin, and paper. The material is selected in consideration of the environment in which the metal nameplates will be used and the method of production. For example, metal plates are used in most cases where the nameplate is outdoors, exposed to wind, rain, direct sunlight, and high or low temperatures. Acrylic sheets are used indoors or when the temperature is constant and not particularly high or low. terminal block of a control device.

The method of displaying and manufacturing the letters varies depending on the material of the board.

A typical example of a metal nameplates are “etched nameplate.” etched by chemical treatment, and paint is then applied to the recessed areas to express letters, lines, or designs.

Another example is a “cast metal nameplates,” in which a wooden or sand mold is used to create a mold with a lettering, into which molten metal is poured at high temperature and allowed to cool and harden. There are “acrylic nameplates,” which is made by carving letters and other characters into an acrylic plate (or various resins, etc.) and expressing them with uneven surfaces.