What Is a Rod End Bearing?

Rod end bearings, incorporating a spherical plain bearing within the housing, are also known as “rod ends” or “spherical plain bearing rod ends.” They are used in assemblies for connecting parts and facilitating relative motion.

Uses of Rod End Bearings

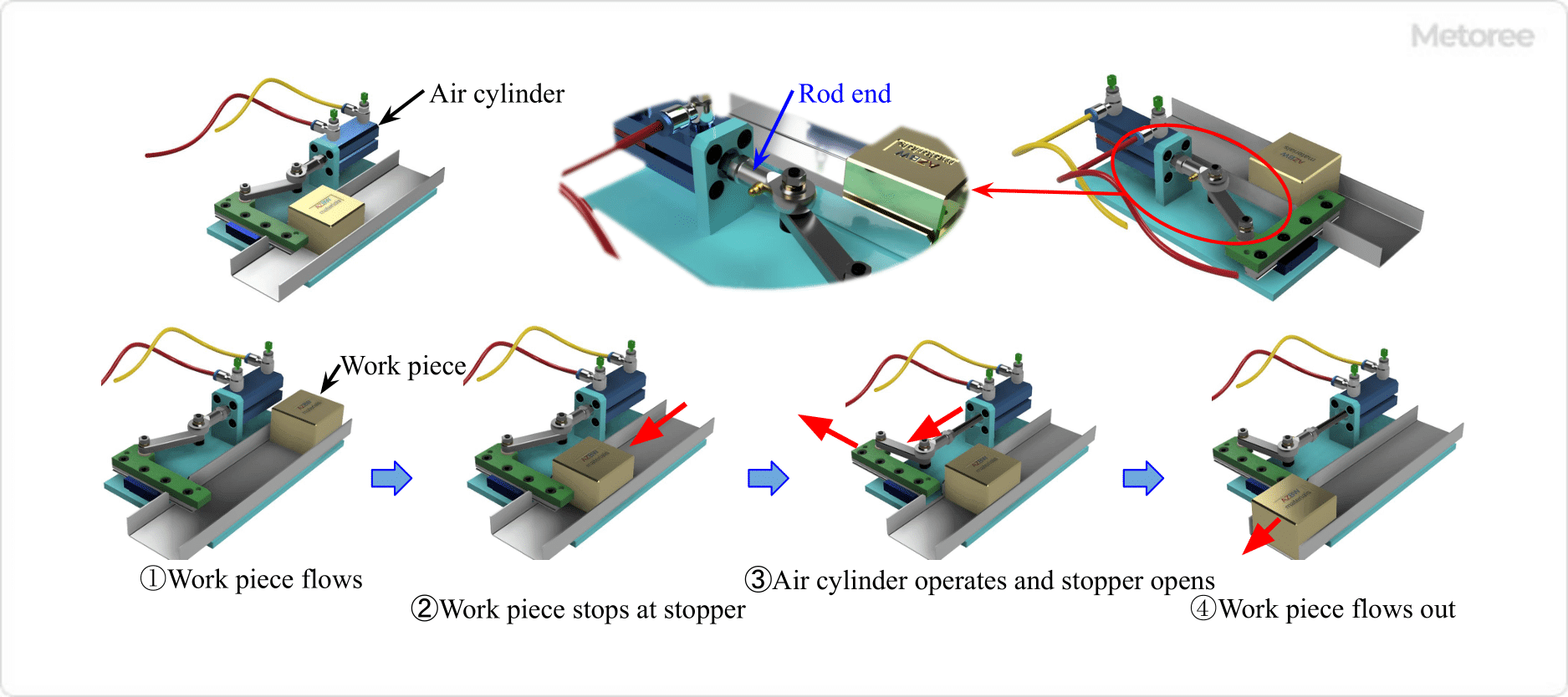

Figure 1. Example of Rod End Bearing Use

Rod end bearings are essential in various sectors, including construction, industrial machinery, automotive, and aviation. They are pivotal in connecting and transmitting motion in parts that undergo rotational or oscillating movements. For instance, as shown in Figure 1, they are utilized in production lines to control the movement of workpieces.

The rod-end housing ends, featuring either “male” or “female” threads, are designed for secure attachment, allowing for the relative displacement of connected parts through a spherical sliding structure.

Principle of Rod End Bearings

Rod end bearings facilitate smooth and flexible rotational motion, enabling connected parts to rotate and tilt freely, akin to human joints. They are capable of withstanding high loads, making them suitable for heavy-duty applications.

Structure of Rod End Bearings

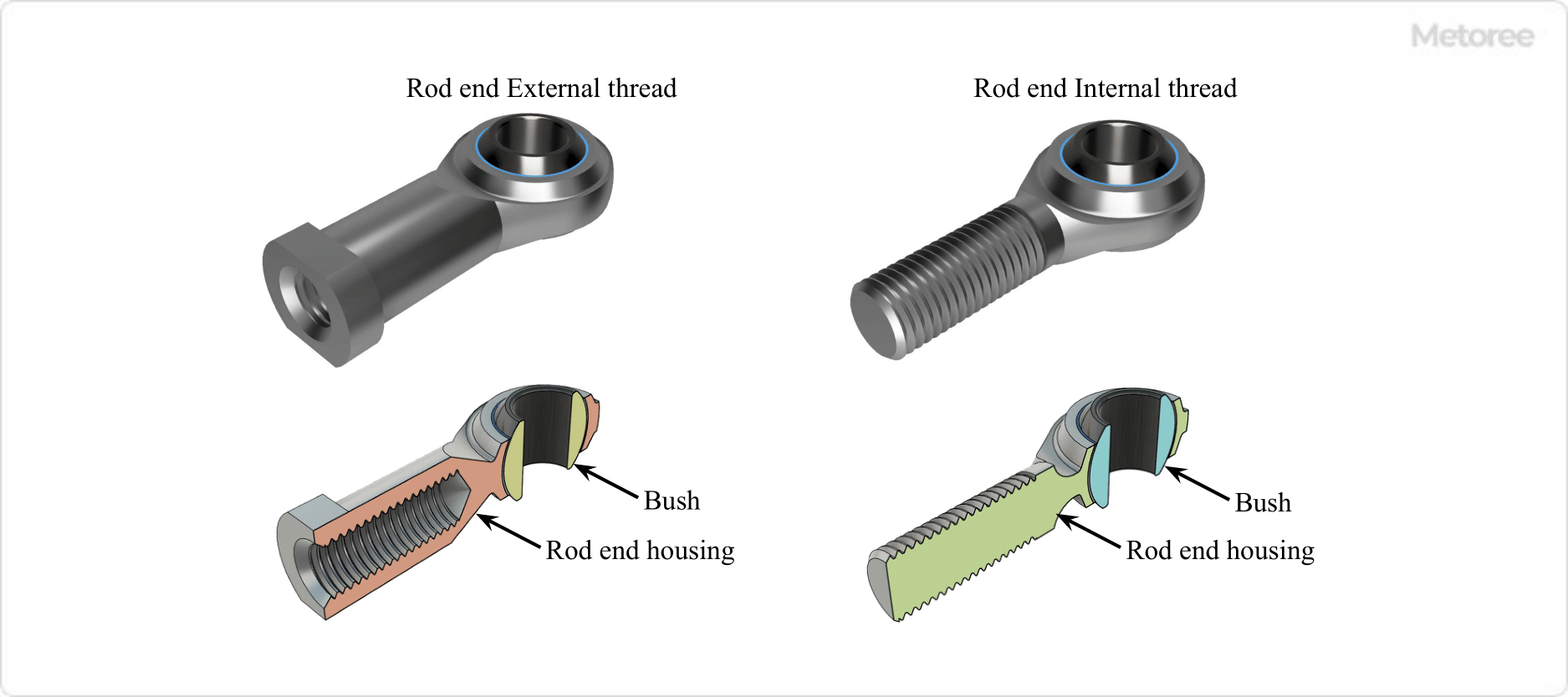

Figure 2. Structure of Rod End Bearing

As depicted in Figure 2, a rod end bearing comprises a “bush” (inner ring) and a “rod end housing” (outer part with threads for connection). These components allow for adjustable connections by threading the male rod into the female-threaded rod end housing.

Types of Rod End Bearings

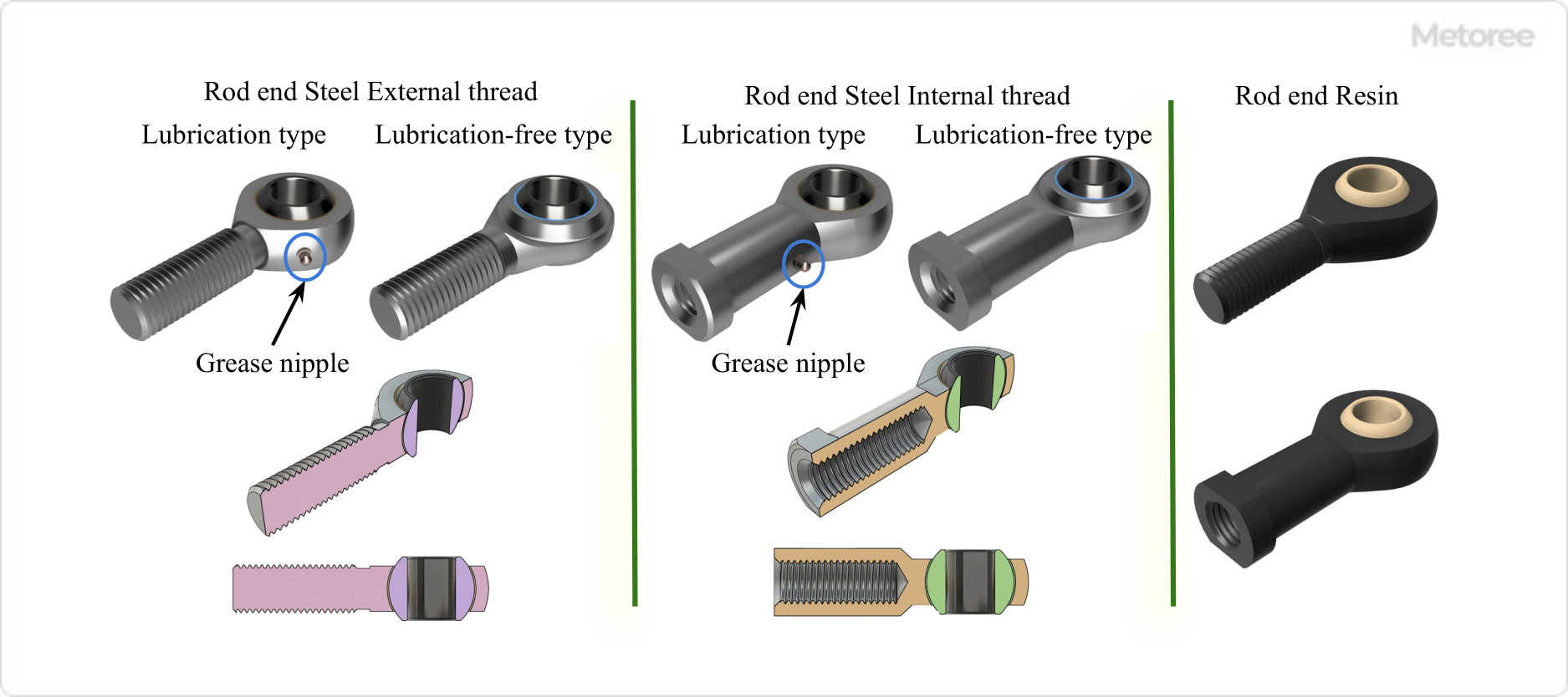

Figure 3. Types of Rod Ends

Rod end bearings vary by shape, lubrication, and material, each tailored for specific applications and requirements.

- Shape: Choose between male and female threaded housings to match the connecting rods.

- Lubrication: Options include lubricated (greased) or unlubricated types, with the latter incorporating a lubricating synthetic resin for maintenance-free applications.

- Material: Materials range from carbon steel to high-carbon chromium-bearing steel and self-lubricating synthetic resins, selected based on environmental conditions and load requirements.

Additionally, resin-made rod ends offer lightweight, maintenance-free options suitable for environments with contaminants.

Others

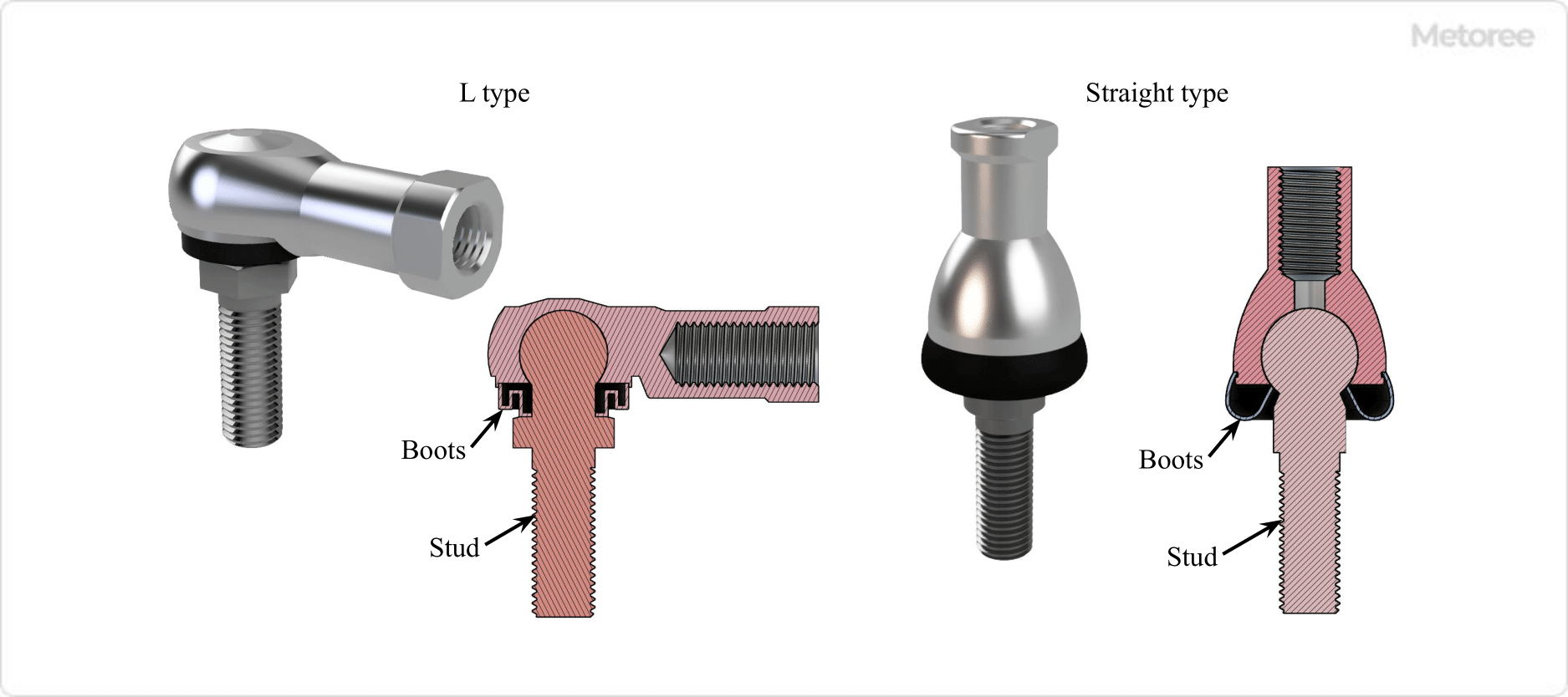

Figure 4. Link Ball

Link balls, another variant, combine a threaded shaft with a bushing, often covered with a rubber boot to prevent ingress of water and dust, with lubricant sealed within for smooth operation.