What Is a CNC Milling Machine?

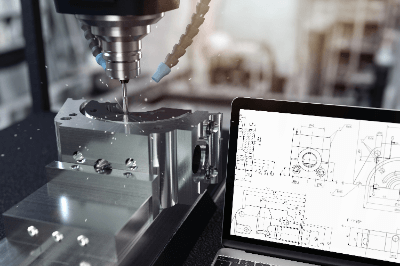

CNC milling machinery refers to milling machines controlled by a computer. CNC stands for “Computer Numerical Control.” In CNC milling, the workpiece is secured on a stage and shaped using a high-speed rotating tool. Various tools are used depending on the machine type, such as face milling and chamfering milling machines. While CNC milling machines with control units can be costly, more affordable versions use PC software for control.

CNC milling machinery refers to milling machines controlled by a computer. CNC stands for “Computer Numerical Control.” In CNC milling, the workpiece is secured on a stage and shaped using a high-speed rotating tool. Various tools are used depending on the machine type, such as face milling and chamfering milling machines. While CNC milling machines with control units can be costly, more affordable versions use PC software for control.

Uses of CNC Milling Machinery

CNC milling machines are widely used in metal processing plants for manufacturing:

- Valves

- Bearings

- Aluminum frames

- Precision equipment parts

- Custom industrial equipment parts

These machines are ideal for precision machining and are commonly used for drilling holes and creating grooves. CNC milling machines offer automated control, simplifying processes that would otherwise require manual skill and experience.

Principle of CNC Milling Machinery

CNC milling machines primarily consist of a control computer, a fixturing table, and various tools:

- Control Computer: Reads drawing files and data to control fixtures and tools.

- Fixturing Table: Typically includes a 2-axis moving stage and a vise for securing the workpiece, all controlled by the computer.

- Tools: Move along one axis and rotate at high speeds during operation, with types including face mills and end mills.

Machining Methods of CNC Milling Machinery

CNC milling machines can perform flat cutting, side cutting, and groove machining:

- Flat Cutting: Uses front-face milling or end milling tools applied perpendicularly to the workpiece.

- Side Cutting: Similar tools to flat cutting, but the application method to the workpiece differs.

- Groove Machining: Employs an end mill for perpendicular application and movement along the groove direction.

Other Information on CNC Milling Machinery

1. Software for CNC Milling Machinery

Software for CNC milling machines converts 2D/3D CAD drawings into motion instruction data (G-code), detailing movement timing, axis rotation speed, tool displacement, and more.

2. Usage Tips and Precautions for CNC Milling Machinery

When using CNC milling machines, consider the following:

- Proper fastening of the workpiece and tool mounting to prevent accidents.

- Setting appropriate machining conditions based on the material and machine specifications.

- Ensuring the G-code travel path does not interfere with the machine to avoid damage and injury.

- Checking tool settings, especially in machines with ATC (Auto Tool Changer) functions.

- Understanding the limitations of machining certain shapes due to the tool’s top-down approach.