What Is Cutting Machinery?

Cutting Machinery is a general term for machines used for cutting metal, wood, and other materials by the use of a grinding wheel, or by using gas, laser, plasma, etc.

Generally, products that cut objects by rotating a grinding wheel at high speed are common. There are also types that fix the object to be cut to a base and cut at a fixed position, and handheld types that can be carried around by hand.

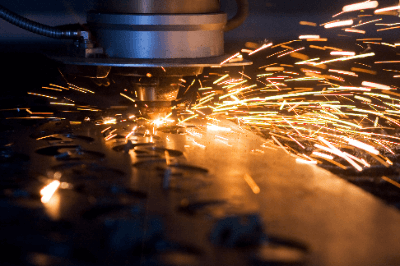

When cutting materials, sparks often fly, so safety precautions such as wearing goggles or protective gear must be taken.

Cutting machines are used in a variety of settings, including manufacturing sites, construction sites, and by DIY enthusiasts, because of their ability to cut quickly and accurately. However, since they require advanced skills and knowledge, it is recommended that they should be operated by professional technicians.

Cutting machines using lasers or plasma have also been developed for situations where more precise cutting is required, and are used to manufacture high-quality products and architectural structures because the cut surfaces are smoother and cleaner than those using grinding wheels.

Cutting machines are indispensable devices for cutting materials, and it is necessary to fully understand how to use them and to handle them safely.

Uses of Cutting Machinery

Cutting machines are used to cut steel, stainless steel, aluminum, wood, and plastic materials.

When selecting a cutting machine, it is necessary to consider whether the machine is compatible with the material to be cut, the amount of power used, and whether the machine is portable.

Various devices are available, such as mechanisms to collect dust scattered by cutting and lights that illuminate the cutting area to make them easier to see the line to be cut.

Cutting Machinery is generally of the type that cuts an object by rotating a grinding wheel at high speed. There are also types that fix the object to be cut to the base and cut it at a fixed position, and handheld types that can be carried around by hand, offering a wide variety of uses.

Principle of Cutting Machinery

In a high-speed rotary cutting machinery, a grinding wheel is rotated at high speed to contact the object to be cut. The grinding wheel is used to cut the object by generating cutting force through friction.

Gas cutting machinery, on the other hand, uses the principle of heating the object with a flame of combustion gas, causing an oxidation reaction through a thermal reaction to cut the object.

Laser cutting machinery uses the principle of cutting by irradiating a laser beam onto the object, which melts the object.

By selecting the appropriate principle and using it in accordance with the characteristics of the object, more efficient and accurate cutting can be achieved. However, since sparks fly and other phenomena occur in any of these uses, extreme care must be taken in handling them, such as wearing goggles and protective gear.

Types of Cutting Machinery

There are three types of cutting machinery:

- High-speed rotary cutting machines

- Gas cutting machines

- Laser cutting machines

Since each cutting machine has a different cutting method, the cutting machinery should be selected according to the intended use. By following the correct handling methods, efficient and safe work can be achieved.

1. High-Speed Rotary Cutting Machine

High-speed rotary cutting machines consist of a circular grinding wheel with a diameter of approximately 300 mm or more, a motor, and a vise. The vise clamps the wood, metal, or pipe to be cut, and the high-speed rotating grinding wheel cuts it. They are characterized by its ability to cut with high precision among manual cutting.

2. Gas Cutting Machinery

Gas cutting machines use a chemical reaction between iron and oxygen to cut steel. Acetylene is mainly used as the gas.

The base material to be cut is heated in advance and then sprayed with oxygen and acetylene to melt the base material for cutting. The features of this method are that it requires less equipment and does not use electricity, but its drawbacks are the cutting speed and the need to keep the base material heated.

3. Laser Cutting Machinery

Laser cutting machines cut by directing a laser beam focused by a lens or other means onto the base material to be cut, and then spraying the area with oxygen or other reactive gas to melt the base material. The area where the base material is heated can be made very small, which enables high-precision cutting.