What Is a 5-Axis Machining Centers?

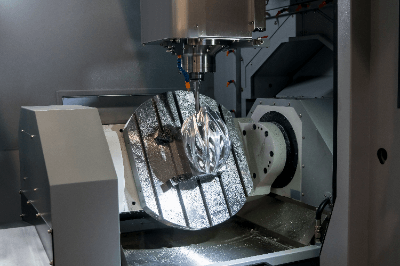

A 5-Axis Machining Center is a machine that has two additional axes, a rotation axis and an inclination axis, added to a 3-axis machining center.

A 5-Axis Machining Center is a machine that has two additional axes, a rotation axis and an inclination axis, added to a 3-axis machining center.

They are capable of more advanced machining than 3-axis machining centers. The machining center has added functions to rotate and tilt the workpiece for automated machining. multiple surfaces can be machined in a single setup, leading to shorter machining times.

Machining centers are also capable of machining complex shapes with high accuracy and are widely used in fields such as aerospace, automotive industry, and medical equipment. In these fields, machining centers are indispensable because they require high precision and high rigidity.

Machining centers are contributing to the advancement of machines and are expected to enable even more sophisticated three-dimensional machining in the future.

Uses of 5-Axis Machining Centers

5-Axis Machining Centers are used in a wide variety of industrial fields that require advanced three-dimensional machining. These include:

- Aerospace industry

Manufacture of parts with complex shapes - Automotive Industry

Manufacture of engine parts and suspension parts - Medical Industry

Manufacture of medical equipment

5-Axis Machining Centers are also utilized in the manufacture of parts that require high-precision machining and are characterized by their wide range of uses. They are also suitable for mass production and minimize the workload of workers, leading to cost reduction.

In addition, since the machine is operated by program control, there is no difference in quality depending on the skill level of the operators. Furthermore, the use of 5-axis machining centers reduce the chance of workers using dangerous tools, thus preventing accidents.

Principle of 5-Axis Machining Centers

The 5-axis machining center adds two axes, a rotary axis and an inclined axis, to an ordinary machining center to enable the workpiece to rotate automatically. It is possible to process parts with complex shapes and curved surfaces, which are difficult to process with a conventional 3-axis machining center.

The use of 5-axis machining centers also depend on whether the tool is mounted horizontally or vertically. Horizontal machining centers have high machining accuracy and can be equipped with a pallet changer that can automatically supply parts, making them suitable for mass production of small precision parts. On the other hand, 3-dimensional machining centers are compact and easy to install because the floor space of the machine itself is small. They are suitable for small-lot production of a wide variety of parts.

Other Information on 5-Axis Machining Center

1. 5-Axis Machining Center Machining Examples

In addition to basic 3-axis machining (XYZ), the 5-axis machining center can simultaneously control the axes that rotate and tilt the table, enabling three-dimensional machining, which is difficult with 3-axis machining.

Because of its ability to draw complex curves and process from multiple angles, it is mainly used in the manufacture of impellers used in jet turbines and air conditioner blowers, the processing of engine intake and exhaust ports in automobiles, and the processing of products with complex shapes, such as various molds, jigs, prototype parts, and semiconductor manufacturing equipment. The 3-axis machining process is also used to process products with complex shapes.

In addition, when 3-axis machining requires machining on multiple sides, or when turning on a lathe or other machine is required after machining operations, setups must be changed after each machining operation. The setup time increases, resulting in poor efficiency, but the 5-axis control allows simultaneous machining from multiple sides, thus reducing setup time. This is also effective for parts that must be delivered in a short period of time.

Furthermore, some 5-axis machining centers are equipped with a function that allows turning by rotating the table at high speed, making it possible to machine products that require separate turning on a lathe without having to change setups.

2. 5-Axis Machining Center Programs

5-Axis Machining Center NC programs require input of not only the basic XYZ, but also angle commands (B-axis and C-axis) for the rotary and tilting axes, and if the angle changes, the machining origin also changes.

Therefore, 5-axis control programs are mainly programmed by drawing (CAD software) and loaded into the machine (CAM software) for machining according to the drawing. Some manufacturers have introduced interactive programs that allow intuitive programming by inputting the shapes to be machined, materials, and machining conditions in sequence, making it possible to create complex programs easily without CAD or CAM software.