What Is a Spindle?

A spindle is a rotating shaft.

The original meaning of spindle relates to the shaft used for winding yarn in a spinning machine. However, in engineering, it primarily denotes the shaft that rotates within a machine tool. Tool blades are attached to this axis to perform machining.

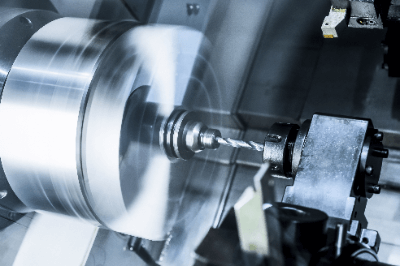

When the blade is fixed and the workpiece rotates, such as on a lathe, it is the shaft on which the workpiece is mounted that rotates. The tool blade and workpiece are attached to the end of the shaft, which is sometimes referred to collectively as the spindle. The rotating object itself or the rotating device itself is also called a spindle unit, or spindle for short.

Other uses of spindles include the center shafts of the rear wheels of FWD cars and the front wheels of RWD cars in automobiles, hard disk drives and storage devices such as DVDs in PCs, and parts of water taps.

Uses of Spindles

Spindle is a device that rotates an object with high precision. Tool knives and workpieces are attached to and detached from spindles, causing misalignment between the axis of rotation and the center axis of the workpiece. This misalignment is called runout and is directly related to errors in machining accuracy.

In addition, if the spindle rotation accuracy is poor, the surface quality of the workpiece after machining will also deteriorate, which will affect the appearance of the workpiece. In addition to the rotational error of the spindle itself, a spindle that rotates stably and with minimal misalignment when attaching and detaching tool knives and workpieces is indispensable for precision machining.

Lathes and milling machines are typical examples of machine tools. Lathes use a spindle to rotate the object. Milling machines, on the other hand, use a spindle to rotate the tool.

Principle of Spindles

Since a spindle is a mechanism or device that performs rotary motion, it requires power to generate rotary motion. Electric motors are mainly used to generate the rotary motion, although some spindles also use pneumatic power.

In most cases, rotational speed and torque are controlled by gears or pulleys, rather than by a motor directly connected to the power transmission in order to process the workpiece under optimum processing conditions. Spindles also generally use bearings to maintain stable and high rotational accuracy.

Some spindles use non-contact bearings such as air bearings or hydraulic bearings to further improve accuracy. Since spindles are structured like the rotating shaft of a machine tool, deterioration is inevitable due to vibration and pressure caused by machining. Therefore, it is necessary to maintain a certain level of rotational accuracy at all times through periodic maintenance and parts replacement.

The most common method of inspection is to attach an inspection tool to the spindle, rotate around of a cylindrical object, and compare the difference in roundness.

Types of Spindle

Spindles can be classified into several types according to their drive system, structure, and accuracy.

1. Externally Driven Spindle

This method is used in combination with other power to rotate by an external motor or other power. Also called a pulley spindle. Speed is increased or decreased to a specific rotational speed.

2. Built-in Motor Spindle

The motor and spindle are integrated into a single unit, also called a motor spindle. The shaft of the motor serves as the spindle, making it compact and enabling high-precision machining. It is used in various machine tools and is also used in robot hands.

3. Air Spindle

Air spindles are spindles supported by hydrostatic air bearings or powered by compressed air. Hydrostatic air bearings support spindles without contact, resulting in low bearing loss, quiet operation, and no contamination by oil. They are suitable for applications where oil cannot be used.

Air spindles that use compressed air have the advantages of high rotational accuracy and minimal thermal deformation of the spindle. An air turbine or similar device is used to drive the spindle. The disadvantage is that the rotational speed is easily affected by cutting resistance due to the low torque. Also called air turbine spindle.

Air motor spindles driven by an air motor are used for low-speed applications. It is suitable for high-torque machining at relatively low speeds.

4. High-Frequency Spindle

This is a spindle with a high-frequency motor built into the spindle. It is used to increase rotation speed or to control rotation speed and torque.