What Is a Turret Lathe

A Turret Lathe is a type of lathe that has a rotatable turret with multiple tools.

A Turret Lathe is a type of lathe that has a rotatable turret with multiple tools.

A turret is a device that can hold and rotate multiple tools. It is fitted with multiple tools and can switch between cutting tools as needed. Lathe Turrets are suitable for small-lot production because they can perform complex work with multiple tools on a single workbench with high precision.

Turret Lathes are characterized by their ability to eliminate the need to change tools, thereby reducing work time and increasing work efficiency.

Recently, automation has been progressing, which improves the accuracy and efficiency of machining and at the same time reduces the workload of the operator.

Uses of Turret Lathes

The main applications of Turret Lathes are as follows:

1. Machining Metal Parts

Turret Lathes can cut a wide variety of metal materials such as steel, aluminum, brass, copper, and alloy steel, and can cut, turn, drill, thread, and groove parts.

In the automotive industry, parts such as shafts, pistons, crankshafts, and gears are manufactured on Turret Lathes.

2. High Precision and Consistent Machining

Turret Lathes can automatically change a large number of tools and perform continuous machining with high precision. They are especially used in the energy industry to manufacture turbine blades, coils, valves, cooling water pipes, etc.

3. Machining Parts With Complex Geometries

Turret Lathes can cut parts with very complex geometries. They are used to manufacture parts for the aircraft industry, such as turbine blades, bolts, nuts, and fuel injectors for jet engines.

4. Prototype Fabrication

Turret Lathes are suitable for the production of small batches of products and prototypes. They are used to produce bolts and nuts for construction parts, door handles, columns, and metal window and door frames.

Principle of Turret Lathes

Lathe Turrets are a processing machine that attaches multiple cutting tools to the material to be processed, and by controlling the position, direction of travel, and speed of the tools, the material is cut out.

Currently, CNC lathes equipped with computerized NC (numerical control) devices are the mainstream, automating some or all of the following processes.

NC stands for Numerical Control. CNC stands for Computer Numerical Control. CNC is an advanced version of NC technology that enables more advanced and precise machining.

How to Use a Turret Lathe

Turret Lathes are used in the following procedures:

1. Install the Material to Be Machined

Fix the material to be processed to the worktable of the Turret Lathe.

2. Select the Cutting Tool

The Turret Lathe can be equipped with several cutting tools. Since the material to be cut and its shape vary depending on the type of tool, select the appropriate tool before operation.

3. Adjust the Position of the Cutting Tool

Adjust the tool position by moving the tool closer to or away from the material to be machined, or by moving it up, down, left, or right.

4. Start Cutting

Cutting is started by bringing the tool into contact with the material to be machined while adjusting the direction and speed of the tool.

5. Change the Tool After Cutting

The tool is replaced with the one required for the next cutting operation.

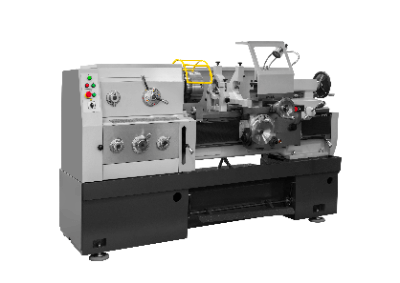

Structure of Turret Lathes

The basic structure of a Turret Lathes is as follows:

1. Spindle Stand

It is the part that supports the spindle, and the motor and gear box to rotate the spindle are mounted. The spindle is the central axis of the lathe and rotates the workpiece. The spindle has a shank (tool mount) to which tools such as tool holders and chucks (devices to hold the workpiece) are attached.

2. Turret (Rotating Tool Rest)

A turret can hold multiple tools and rotate perpendicular to the centerline of the Turret Lathe. It is characterized by its ability to use multiple tools without having to change cutting tools, thereby increasing productivity. Since a single worktable can process with a variety of tools, it is suitable for high-mix, small-lot production.

3. Reciprocating Table

The reciprocating table can move horizontally across the lathe and carry tools for shaving workpieces. It can also be moved vertically, allowing adjustment of the depth to which the workpiece is machined.

4. Feed Device

The feeder is a device used to accurately move the workpiece along the reciprocating table. Feed devices include mechanical feed devices and computer-controlled feed devices (CNC lathes).

5. Bed

The bed is one of the basic components of a lathe, supporting the spindle and reciprocating table. Since it is made of highly rigid cast iron or steel, the lathe as a whole is highly stable and can perform high-precision machining. The bed is equipped with rails for the spindle and reciprocating table to move.

Other Information on Turret Lathes

1. Types of Cutting Tools

Tools used on Turret Lathes include external cutting tools, internal cutting tools, threading tools, grooving tools, and chamfering tools. Various shapes can be machined by combining these tools.

2. Types of Machining

Turret Lathes are capable of not only cutting but also drilling and grooving. By attaching a drill chuck to the lathe part, precision drilling can be performed using tools such as drills and reamers.

A reamer is a type of tool used for high-precision drilling of metal or plastic workpieces. A reamer is a cylindrical bar-shaped component with a conical tip. The tip of the reamer consists of multiple blades that gradually increase in size, which are inserted into the workpiece while rotating to accurately enlarge the inside diameter of the workpiece.