What Is a Rotary Table?

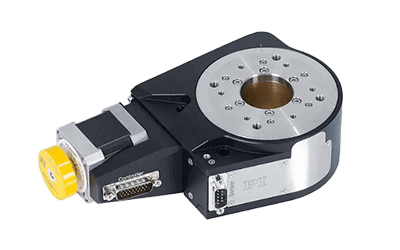

A Rotary Table is a rotating platform on which a device or object is mounted.

Rotary Table is used to rotate an object mounted on it to a desired orientation or angle, for positioning, or for measurement. The method of rotation can be manual or motorized. The control method can be open-loop or feedback control, and the size can be large or small, so it is important to select the right one depending on the application.

In addition, rotary tables are rarely used by themselves, as rotary motion is often accompanied by some subsequent operation, such as processing or measurement.

Rotary Table Applications

Rotary Tables are used to hold semiconductor wafers for inspection, precision measurement, and motion simulation. They are also used for precision measurement by fixing optomechanical components.

The Rotary Table itself can be mounted in a variety of orientations. It is used after considering whether it is more efficient to rotate the object to be processed or measured or the mechanical parts of the equipment.

High precision is required depending on the application: manual coarse rotation is used when a rough angle is required, while fine rotation is used when fine angle adjustment is required.

Principle of Rotary Table

Rotary Table has a cross roller bearing structure, a sliding structure, and an angular bearing structure.

1. Cross Roller Bearing System

A cross roller bearing consists of a roller race with a 90° V-groove and a cylindrical roller. The cylindrical rollers are arranged orthogonally and alternately with a contact angle of 45°. The back bearing structure in a ball bearing can be realized with a single row, enabling the bearing to receive loads from multiple directions simultaneously.

When the Rotary Table is driven, multiple cylindrical rollers roll on the roller race, which is characterized by almost no change in friction from stop to start. The cross roller bearing supports the load with linear contact and is a more rigid system than the ball guide mechanism. In addition, the rotary stage and cross roller bearing can be directly connected, which reduces the number of structural parts.

Since the rotational accuracy of the Rotary Table depends on the accuracy of the rollers, high rotational accuracy can be obtained depending on the accuracy grade of the rollers. In addition, since cross roller bearings have low frictional force and can be operated with light force, micrometer heads and other devices can be used in the fine rotation mechanism to obtain high positioning accuracy.

By connecting a stepping motor to the rotation mechanism, the angle and direction of rotation, as well as the operation procedure, can be automated.

2. Sliding Method

This is a sliding method in which one surface of the Rotary Table and one surface of the fixed side come into contact with each other. This is called dovetail sliding. The mechanism is simple, and dirt is difficult to get into the gap. Since the supporting area is large, it can withstand impact loads and large loads.

3. Angular Bearing System

Angular bearings are bearings with a contact angle to receive axial loads in one direction. When used in Rotary Table, two angular bearings are used and placed facing each other. This method provides greater rigidity for both axial and radial loads.

4. Motor-Driven

Stepping motors are often used for motorized Rotary Tables. The basic step angle is 0.36°, and the resolution is 0.004° at full step and around 0.0002° at microstep of 1/20 division.

Features of Rotary Table

1. Fine Movement Mechanism

In addition to the coarse rotation mechanism that allows 360° rotation, the Rotary Table is equipped with a fine rotation mechanism that allows fine rotation in a specific range. The fine movement rotation is performed by a worm and gear drive using a precision micrometer.

The range of fine rotation is generally ±3 to 5°. The resolution is about 5 arc-min on a vernier scale.

2. High Rigidity

The Rotary Table has very low deformation, wobble, and backlash. Axial wobble is generally less than 500 μrad.

3. Functionality

Some Rotary Tables can be used in Class 100 clean rooms. Many are also compliant with the European RoHS Directive. The coarse and fine rotation mechanisms can be locked by screws.