What Is Molding Machinery?

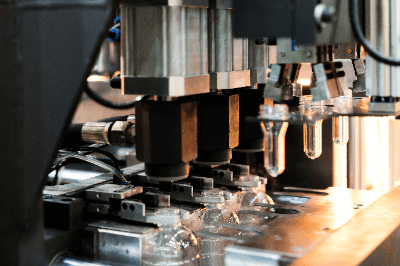

Molding machinery is machinery used in the molding of plastics and resins.

Molding machinery is machinery used in the molding of plastics and resins.

Specific uses include the manufacture of appliances and components. Extrusion machinery is used to produce tubes and rod products, molding machinery is used for styrene foam, and blow molding machinery is used for hollow products.

Molding machinery includes specialized machines for fluoroplastics, which are difficult to process, and vacuum molding machines, which mold under vacuum conditions, enabling high-precision molding. Molding machinery is suitable for mass production, but is now also used for small lot production.

For this reason, flexible molding machinery that can be switched in a short period of time has also been developed.

Uses of Molding Machinery

Molding machinery can mold a wide variety of materials, including plastics, metals, rubber, and ceramics. In the automotive and electrical/electronics industries, they can produce parts with complex shapes.

In the medical field, they are used in producing medical devices and prosthetics. They are also used in the construction industry to produce plastic exterior materials and roofing materials, in the food industry to produce chocolate and silicone molds, and in the textile industry to produce accessories and fabrics for spinning and weaving machines.

Principles of Molding Machinery

1. Injection Molding Machinery

Injection molding machinery consists of heating plastic raw materials and other materials, injecting them through an injection port, and placing them in a mold. In extrusion molding machinery, plastic materials are placed in a hopper, pushed out through an extrusion opening, and shaped by a mold.

2. Extrusion Molding Machinery

Molding machinery is a machine that extrudes thermoplastic materials by means of special mechanical pressure and heating. Plastic particles are fed from the machine’s feeder and melted by a heated screw.

The plastic material extruded at high pressure is then formed to fit the shape of the die, creating a shape. Finally, the formed product is cooled and separated by a cooling system.

3. Blow Molding Machinery

In blow molding machinery, plastic material is heated and placed into a hollow shaped die, which is inflated by air pressure to form the product. In molding machinery, thermoplastic resin is injected into the mold, cooled, and formed. In vacuum molding machinery, heated plastic film is applied to the mold under vacuum conditions.

Molding machinery performs molding operations in a high-temperature, high-pressure environment, so safety measures are important. In addition, factors that affect the quality of molded products include the type and quality of raw materials, mold design, and the adjustment of molding conditions. Molding machinery is suited for mass production, but today, flexible molding machines that can be switched in a short time are being developed to accommodate small-lot production.

Types of Molding Machinery

Molding machinery includes injection molding machinery, extrusion molding machinery, and blow molding machinery.

1. Injection Molding Machinery

Injection molding machinery is a machine that molds plastic material by injecting it into a mold. Injection molding machinery is characterized by its ability to mass produce at high speed. They are also highly automated, with operators simply operating the machine, which automatically performs everything from molding to ejection.

Injection molding machinery heats plastic material to melt it, and then injects the plastic through the injection port to form the mold. The plastic injected into the mold cools and hardens to form the desired shape.

Injection molding machinery is used for many products such as car panels, bumpers, computers, scissors handles, syringes, and smartphone covers. Mold design and manufacturing technology are important, as molds need to be designed according to the material and shape.

2. Extrusion Molding Machinery

Extrusion machinery is a machine that melts plastic, rubber, metal, or other materials and pressurizes and extrudes them to make tubes, sheets, profiles, pipes, and other shapes.

Plastic or resin is placed in the hopper, and the material is fed into the screw while adjusting the amount. The material is heated inside the screw to melt it and extrude it. At the end of extrusion, a mouthpiece called a die is attached to determine the shape.

3. Blow Molding Machinery

Blow molding machinery is a machine that uses air pressure to expand the material, which is then cooled and hardened as it is pushed into the die.

The temperature is raised to soften the material, which is then extruded through an extrusion screw to form a parison. The parison is cooled and molded by pressing it against the mold while blowing compressed air into it.