What Is an Industrial Microscope?

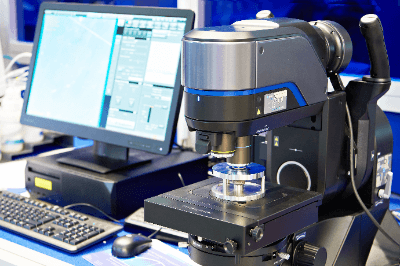

Industrial microscopes are used for process inspection and analysis in the manufacture of semiconductors, electronic components, and liquid crystal displays.

Industrial microscopes are used for process inspection and analysis in the manufacture of semiconductors, electronic components, and liquid crystal displays.

To facilitate data analysis, most industrial microscopes are equipped with a digital camera or CCD to capture images on a PC.

Uses of Industrial Microscopes

Industrial microscopes are used for manufacturing process inspection and analysis of industrial products, such as semiconductors and electronic components. The most common industrial microscope is the metallurgical microscope, which is used to observe surfaces by irradiating light and using reflected light.

Metallurgical microscopes are used for surface observation of opaque industrial products, such as ceramic structures, metals and alloys, polished surfaces of components, and electronic parts. They are also used for development, analysis, and inspection during the manufacture of products such as magnetic heads, liquid crystals, and films.

It can also be used for detailed observation of solder joint surfaces on circuit boards and the depth of penetration of welds. They are also used for evaluation and analysis after casting, heat treatment, and metallurgy in metal processing.

Principle of Industrial Microscope

The two most common types of industrial microscopes are the upright microscope, which is used to view the sample from above, and the inverted microscope, which is used to view the sample from below. The upright microscope is the most common and common type of microscope. The sample is placed under the objective lens and observed from above the objective lens. In an inverted microscope, the tip of the objective lens is on the upper side and the specimen is observed from below.

In both upright and inverted microscopes, the light source is located inside the objective lens. The light source illuminates the surface of the sample, and the reflected light from the sample surface is used to observe the shape of the sample surface. A prism or lens is placed between the objective lens and the eyepiece lens, and the light irradiated from the objective lens side to the sample and reflected back is magnified for observation. Magnification ranges from 50x to 1,000x.

There are many types of metallurgical microscopes used for Industrial Microscopes that have multiple functions, and there are a wide variety of models that can perform bright-field, dark-field, and differential interferometry with reflected illumination. In the dark-field method of reflected illumination, fine scratches, cracks, and pores appear shining and are suitable for observation of the specimen surface. In the differential interference method with reflected illumination, fine irregularities that are difficult to detect with the bright-field method can be detected, and it is widely used in inspection processes.

Types of Industrial Microscopes

As mentioned above, there are two types of industrial microscopes: upright microscopes and inverted microscopes.

1. Upright Microscope

In general, upright microscopes have the advantage that both transmission and reflection can be selected according to the illumination method, and the optical system can be easily designed.

2. Inverted microscope

Inverted microscopes are often used in the field of metals, etc., because the surface to be observed is placed in a downward position, allowing the observation surface to be easily leveled with respect to the optical axis.

Other Information on Industrial Microscope

1. Industrial Microscope With Multiple Functions

Industrial microscopes have not only the function of a metallurgical microscope but also other functions for efficient observation. For example, some models have multiple observation methods, including ordinary optical microscopes, polarizing microscopes, and scanning probe microscopes.

In addition, since industrial microscopes are used for manufacturing process inspection and analysis of industrial goods, they are generally capable of importing CCD or digital camera images into a PC. This facilitates data analysis, thereby improving the efficiency of inspection and analysis.

Furthermore, there are Industrial Microscopes that combine several functions, such as a camera and 3D measurement, in addition to the microscope function.

2. Difference Between Industrial Microscope and Measuring Microscope

An industrial microscope is, in a broad sense, a generic term for microscopes used in manufacturing and other industrial fields. Therefore, not only optical microscopes but also electron microscopes and digital microscopes fall under the category of industrial microscope. However, the industrial microscope generally refers only to optical metallurgical microscopes.

Metallurgical microscopes often use reflective illumination to shine light on the surface of the object to be measured, and their primary use is for surface observation. Measuring microscopes, on the other hand, use transillumination in addition to reflective illumination. In addition, the stage on which the object to be measured is placed is equipped with a digital scale and counter as standard equipment, and has mechanisms and functions for measurement.

In other words, industrial microscopes are mainly used for observation, and do not require the same amount of stage movement or magnification guarantee for the magnified observation image as measuring microscopes.