What Is Brake Lining?

Brake Lining is a friction material that is a component of the brake system. Brakes convert kinetic energy into thermal energy through friction. Brake lining is the friction material that provides that friction.

Brake Lining is a friction material that is a component of the brake system. Brakes convert kinetic energy into thermal energy through friction. Brake lining is the friction material that provides that friction.

However, brake lining is not used in regenerative braking where there is no physical contact. Generally, those attached to disc brakes are called pads, while those attached to drum brakes are called shoes.

Uses of Brake Lining

Brake Lining is used for equipment in which a braking system is incorporated. They are used in a wide range of applications, from industrial to consumer products, and the main examples of their use are as follows:

- Inside a disc brake used on the front wheels of an automobile

- Inside a drum brake used on large vehicles

- Inside a band brake used on a bicycle or washing machine

- Inside a disc brake used on an elevator hoist

Principles of Brake Lining

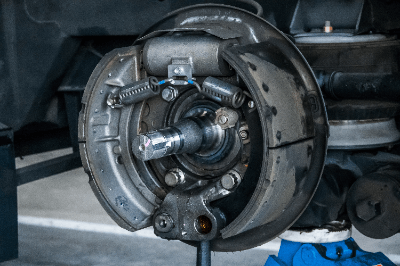

Brake devices that use brake lining include Disc Brakes, Drum Brakes, and Band Brakes.

The principle of each is as follows:

- Disk brake

In a disc brake, friction is generated by sandwiching the rotor, which rotates with the shaft, between the brake lining. - Drum Brakes

In a drum brake, the brake lining is pressed against a drum that rotates with the shaft to create friction. - Band Brake

A band brake generates friction by tightening the drum, which rotates with the shaft, with a band with Brake Lining.

All brakes convert kinetic energy into thermal energy. When selecting brake lining, there are conditions such as operating temperature and coefficient of friction.

In addition, factors such as discomfort noise and vibration during braking also exist, so the types and blends of friction material materials vary widely, with more than 10 different raw materials blended together to make the product.

Other Information on Brake Lining

1. Brake Lining and Pads

Brake Lining and Brake Pads are both wear parts used in brakes. For drum brakes, they are called “Brake Lining” and for disc brakes, they are called “Brake Pads”.

Both are abrasion materials, which wear during braking to slow down the object. In the case of automobiles, materials are used that function reliably even when affected by snow and mud.

In the case of a vehicle that repeatedly drives at high speed and stops abruptly, such as a racing car, the brake linings generate a lot of heat and turn bright red. A material that does not impair braking performance under these conditions should be used. In order to use brake linings that are appropriate for the vehicle, it is preferable to use the manufacturer’s original brake linings when replacing them.

2. Replacement of Brake Lining

Brake Lining is designated as a periodic replacement part because it wears out with use. Replacement timing is determined by checking the mileage and measuring the amount of wear. Longer mileage increases the frequency of braking, and thus the wear of brake lining is more likely to progress.

Even when the mileage is short, premature wear may occur due to frequent emergency braking or overloading. The amount of wear should be measured during periodic inspections, and if it is close to the replacement threshold, replacement of brake lining is recommended. In many cases, brake lining wear can be detected by a change in brake sound.

As the brake lining wears down, a high-pitched “squealing” sound is heard when the brakes are applied. This is because the metal parts of the brake linings begin to contact each other due to wear. If you hear this unpleasant sound when braking, you should replace the brake lining as soon as possible. Continued driving under this condition may result in a serious accident due to reduced braking force.