What Is Milling Processing?

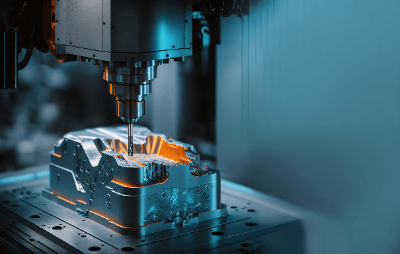

Milling processing, often simply referred to as milling, is a machining method that involves moving a rotating tool with cutting teeth to shape a workpiece. This process uses rotating tools like end mills and milling cutters, hence the term milling.

Milling machines and machining centers are commonly used to finish workpieces of various shapes, including angular, boxy, and cylindrical forms.

Different types of milling processing include flat processing, side processing, groove processing, step processing, and hole processing.

Uses of Milling Processing

Milling processing is predominantly used for part manufacturing in machinery components and molds. It employs rotating tools at high speeds to cut materials while moving them in multiple directions. This method is essential in manufacturing settings where precise cutting operations are needed. In mass production factories, machining centers are prevalent, while general-purpose milling machines are favored for small-scale or precision machining.

Types of Milling Processing

Milling processing varies based on the desired shape and material characteristics. Broadly, it can be categorized into five types:

1. Flat Processing: Cutting the material’s surface parallel to the table, with methods like face milling for large areas, plain milling for top surfaces, and end milling for smaller areas.

2. Side Processing: Involves cutting the material’s side, using face milling for large areas, side milling for roughing, and end milling for common side cuts.

3. Step Processing: Cuts both the material’s surface and side simultaneously, with face milling for broad surfaces, side milling for steps, and end milling for narrow surfaces.

4. Groove Processing: Cuts grooves into the material using end mills, with variations like pocket milling and helical milling.

5. Hole Processing: Creates holes in the material, starting with drilling and expanding with end milling.