What Is a Wing Pump?

Wing pumps are a type of plain bearing that does not use oil, grease, or other lubricating materials.

Plain bearing lubricant, such as oil or grease, is applied between the bearing and the shaft to reduce friction and maintain sliding properties. Wing pumps, however, do not require the application of oil, grease, or other lubricants, or can reduce the amount and frequency of lubrication.

Uses of Wing Pumps

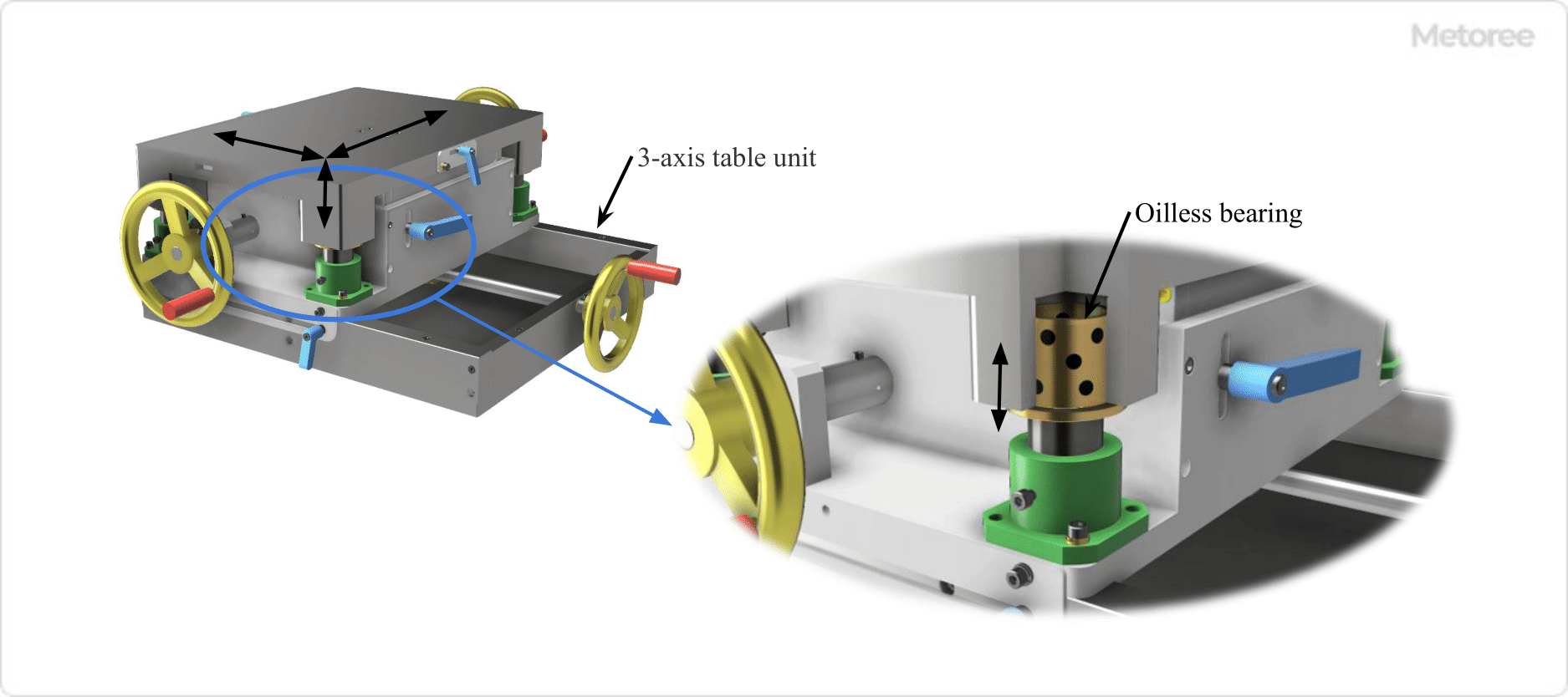

Figure 1. Example of oilless bearing use

Wing pumps are used in sliding and rotating parts in the following cases.

- Locations where oil supply or lubrication is not possible due to structural or installation location restrictions

- High and low temperature atmospheres

- Corrosive atmospheres such as underwater or where chemicals are used

- Atmospheres where dust or other contaminants are present.

- Locations subject to high shock loads and vibration.

- Locations where lubricants such as oil are not effective due to frequent startup and shutdown.

Wing pumps are used in sliding and rotating parts in a wide range of fields, including industrial machinery, automobiles, railcars, industrial robots, copiers, and printers. When they are used in high-temperature valves and steelmaking equipment, for example, they are an example of utilizing their superior heat-resistant characteristics.

Other examples of applications that take advantage of the absence of oil or other lubricants include food manufacturing equipment, medical and nursing care equipment, and underwater equipment such as sluice gates and water wheels. Figure 1 shows a table position adjustment mechanism in three axes, horizontal (right and left) and vertical, in which wing pumps are used to support the vertical axis.

Principle of Wing Pumps

In a plain bearing, the bearing and shaft are in contact with each other, so friction occurs and wear develops as the shaft rotates. Oilless bearings do not use oil or other lubricants on the sliding surfaces, but rather provide self-lubricating properties and form a lubricating film to reduce friction.

The following methods are used to make wing pumps self-lubricating.

- Embedding solid lubricant in the sliding surfaces

- Dispersing the solid lubricant in the metal structure

- Oil impregnation within the metallic structure

- Using a resin material with excellent self-lubricating properties

Types of Wing Pumps

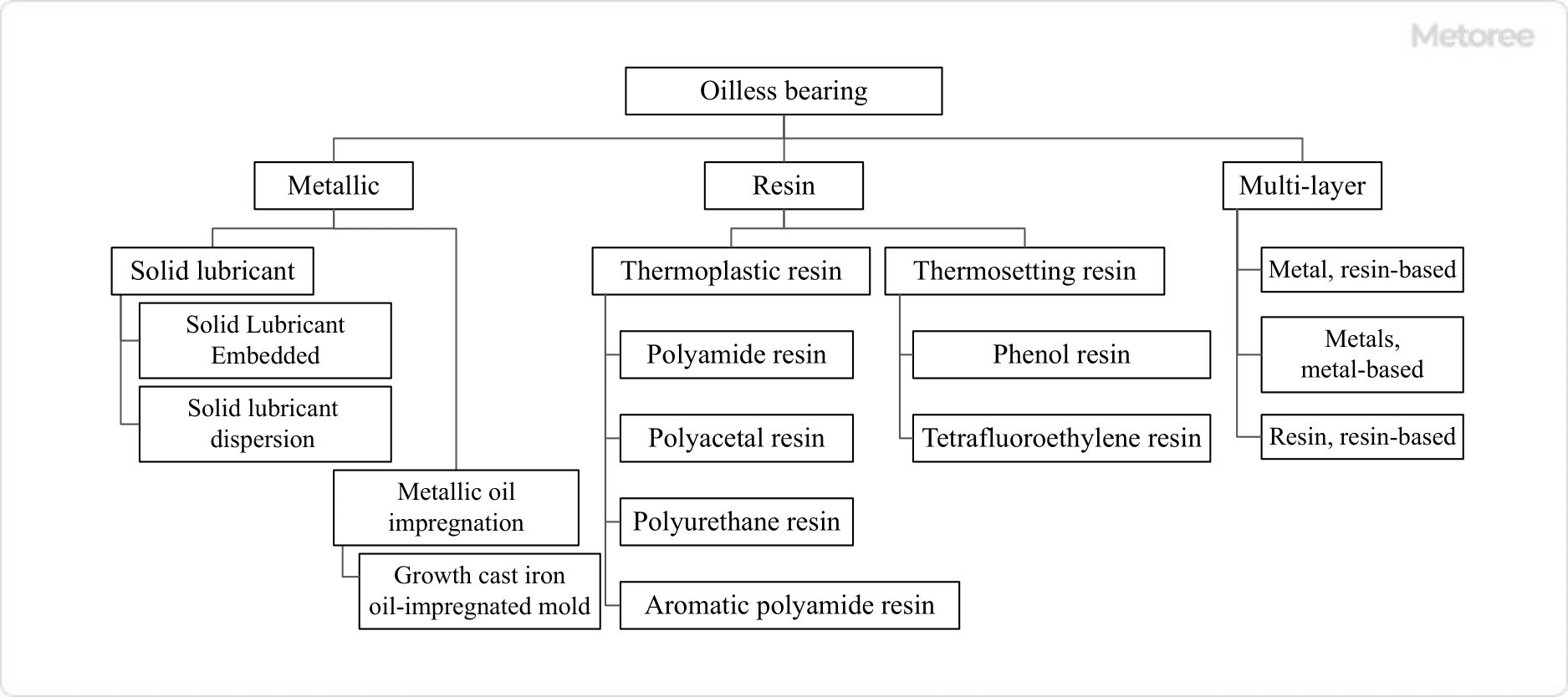

Figure 2. Types by material

1. Classification by Material

There are three major types of oilless bearings by material: metallic, resinous, and composite.

Metallic Type

Metallic wing pumps include “solid lubricant embedded type,” in which a solid lubricant with excellent self-lubricating properties is embedded in the sliding surface of a copper alloy or other material, “solid lubricant dispersion type,” in which the lubricant is dispersed within the metal structure, and “oil-impregnated growth cast iron type,” in which the oil is impregnated in cast iron or other material.

Resin Type

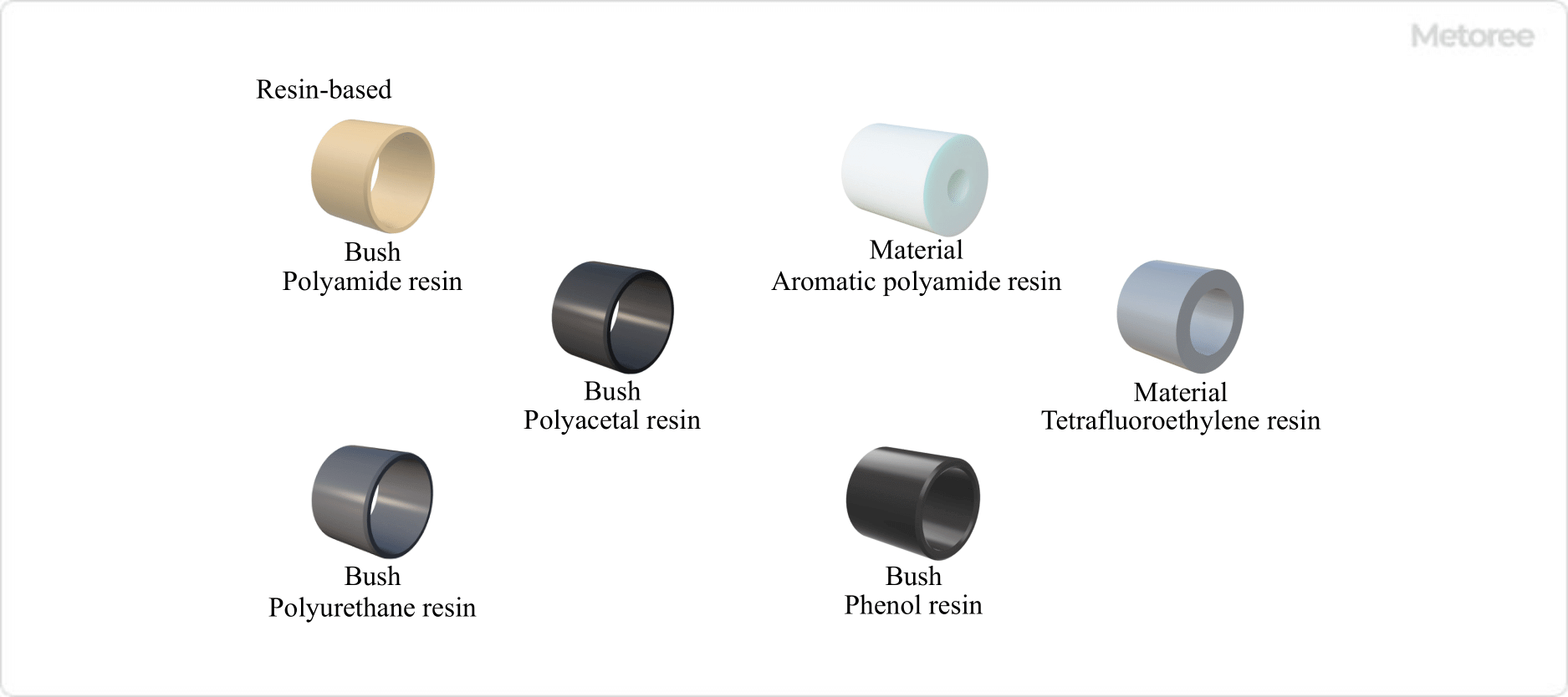

Resin-based wing pumps are made of thermoplastic resins such as polyamide resin (PA), polyacetal resin (POM), polyurethane resin (PUR), and aromatic polyamide resin, and thermosetting resins such as phenol resin (PF) and tetrafluoroethylene resin.

Double-Layer Bearing

Multilayer wing pumps are molded from a combination of self-lubricating materials and materials with superior strength and thermal conductivity.

2. Classification by Shape

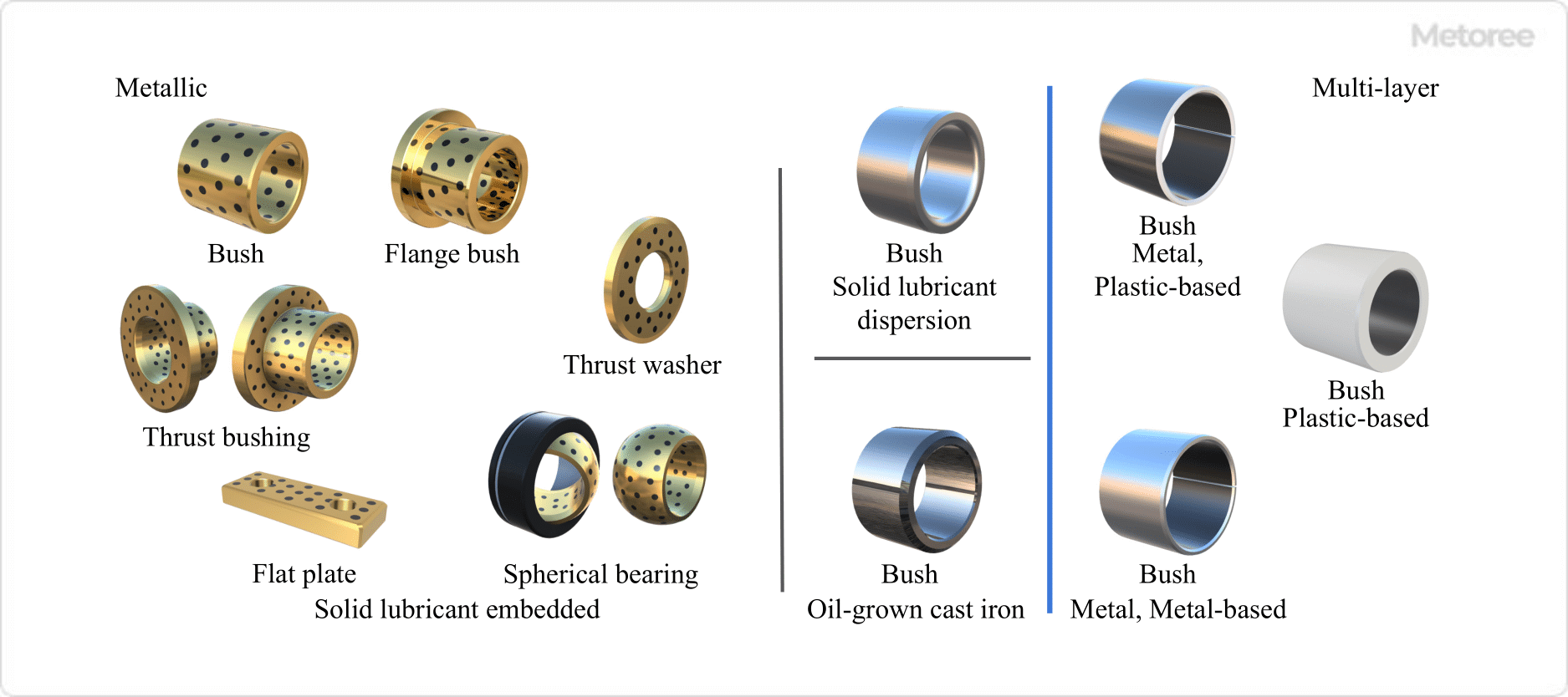

Figure 3. Types by material (Metallic)

When used as bearings, there are cylindrical “bushings” and cylindrical “flange bushings” with a flange, and when subjected to thrust loads, there are cylindrical “flange bushings” with a flange and disk-shaped “thrust washers. Spherical plain bearings” of the spherical plain bearing type are also available.

Figure 4. Types by material (Resin-based, Multi-layered)

Other Information on Wing Pumps

Maintainability

Wing pumps do not require an oil supply system. Oil consumption is almost zero, and some bearings can be used without lubrication.

Equipment and operating costs are reduced, and periodic maintenance is not required. However, wear may develop and the bearings will need to be replaced.