What Is a Shape Measurement Sensor?

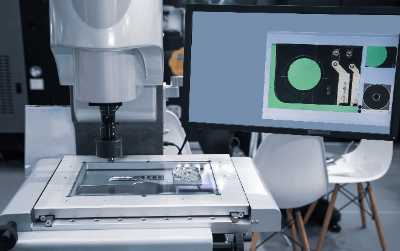

A shape measurement sensor (profile measurement sensor) is a device that measures the shape of an object.

A shape measurement sensor (profile measurement sensor) is a device that measures the shape of an object.

It is a type of displacement sensor that measures thickness and length, and is often called a shape measurement sensor, especially when it measures curved surfaces, depth, and complex shapes. They are used in manufacturing sites in a wide range of industries, from food to industrial products.

The most common type is a non-contact laser measurement type, which is selected according to the object and the required measurement accuracy.

Applications of Shape Measurement Sensors

Shape measurement sensors are mainly used to measure the external shape of products. They are used for checking the cracks, chips, dents, area, volume, and other finished shapes of products, as well as the state of assembly of parts.

For example, in the food industry, it can automatically detect cracks and chips in cookies and rice crackers, etc. In the case of 3D measurement type products, it can also detect area and volume.

In the case of industrial products, the system can be used to automatically determine whether the processing results of various processed products are good or bad. They are also used to check the shape of welding finishes.

Types of Shape Measurement Sensors

1. Optical Displacement Sensor

There are two types of sensors based on the detection principle of triangulation: those using a PSD as the attending element and those using an image sensor.

2. Linear Proximity Sensor

When an alternating current is applied to a coil, magnetic flux is generated, and when it passes through a metallic object, eddy currents are generated against the object. The direction of this eddy current is such that it generates a magnetic flux that interferes with the generated magnetic flux change.

As a result, the inductance of the coil changes, and by reading the amount of change in inductance, the distance displacement between the coil and the object can be measured.

3. Ultrasonic Displacement Sensor

An ultrasonic wave transmitter is used to send ultrasonic waves to an object, and a receiver is used to receive the reflected waves. The distance is calculated by measuring the time between the transmission and reception of ultrasonic waves.

Principle of Shape Measurement Sensor

1. Optical Cutting Method

In the non-contact laser optical cutting method, a laser is emitted from the sensor on a line, reflected off the object to be measured, and received by the light receiving part (element) to measure the distance to the object. From the measured distance, the actual shape is calculated using triangulation, and shape data can be created.

2. Measurement Resolution

The entire object is measured continuously by moving the object on a conveyor-like line against a sensor fixed at an arbitrary position. One of the measurement resolutions is determined by the number of times the sensor is captured per unit of time. For example, if a line moves 1 meter per second and captures 1,000 times per second, it is possible to capture the shape in increments of 1 mm.

The results of the measurement are processed by computer and displayed on a display to confirm the results. Some products automatically process measurement results, such as width, height, area, and volume.

Shape measurement sensors are based on the principle of shining a light on an object and having the light reflect off it, so that specialized sensors are required to measure the shape of objects made of glass (such as CCDs and CMOS in electronic components and crystal pieces in quartz crystals), rubber products (such as tires), and objects with colors that do not reflect well.

Other Information on Shape Measurement Sensors

Triangulation

Triangulation is a method of measuring distances between distant points using the principle of triangulation. If the exact distance between two points is known, the distance to a point at a distance from those two points can be calculated as long as the angles between the two points are known.

This is based on the property that a triangle is determined when one side of the triangle and its two end angles are determined.

One of the advantages of the triangulation method in a shape measurement sensor is that it is not easily affected by colors or backgrounds. Unlike the general light-receiving discrimination type, the distance is determined by the laser light reflected from the surface of the workpiece, so the influence of the color and material of the workpiece and background can be suppressed.

For example, even if the workpiece and background are the same color, stable position determination is possible.