What Is an Industrial Tablet?

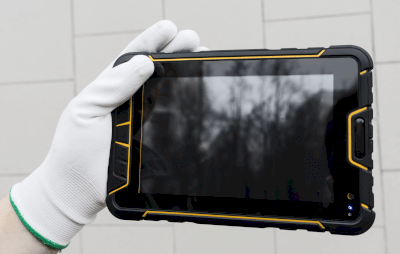

Industrial tablets are tablet PCs that can be used for on-site work.

Tablets are lightweight and easy to carry, and have been widely used in general households. In recent years, there has been an increase in the number of applications in various industrial fields to improve work efficiency and productivity.

On the other hand, the specifications required for on-site work differ greatly from those of personal tablet PCs. For example, in addition to durability, such as waterproof, dustproof, and shock resistance, and high performance for comfortable operation, security robustness is required to prevent information leakage.

Uses of Industrial Tablets

Industrial tablets can be used for in-vehicle terminals that are subject to vibration and shock. Others are used outdoors, such as at construction sites where they are exposed to rain and wind. They can also be used indoors where water droplets and dust are a concern, such as machinery manufacturing sites and food processing plants.

Since different sites require different performance and functionality, industrial tablets are customized. For example, they can be fully waterproof for use in wet areas, or painted to match corporate colors.

Industrial tablets are available with a wide range of accessories. Specifically, cradles, shoulder straps, hand straps, etc. can be utilized depending on the application.

Structure of Industrial Tablets

Industrial tablets, like regular tablets, consist of the CPU, memory, and other parts that make up a PC, as well as a touch panel display.

Tablets use a common operating system (OS) such as Windows, with enterprise versions such as Windows 10 IoT Edition.

A new version of a typical OS is released every two to three years and must be updated for continued use. Compatibility with older versions means that some tablets can no longer be used with previously used software or devices. On the other hand, industrial tablets are updated in relatively short periods of time, such as two to three years, and incompatibility is not desirable for business purposes. For this reason, industrial tablets are often equipped with operating systems that do not require functional updates.

How to Select an Industrial Tablet

When selecting an industrial tablet, it is necessary to consider the environment of the site where it will be used.

For example, dust and waterproof performance are required for construction sites, factories, and outdoor sites, where dust and water may enter. Furthermore, not only are cold and shock resistance often required, but the communication environment is also important.

When used for inventory management or transportation management in warehouses, etc., it is necessary to check whether the inventory management system or picking system installed in the company can be installed in order to improve operational efficiency. In addition, when used outdoors, such as at construction sites, the screen must be able to be operated by touch without problems even if it rains, the screen gets wet, or the user is wearing gloves.

1. Dustproof and Waterproof

Dustproof and waterproof are important features for tablet use in the field. General tablet PCs are also waterproof, but the amount of dust and moisture generated in the field differs greatly, so a higher level of dustproof and waterproof functionality is required. For this reason, industrial tablets are covered with a thick case around the tablet and other measures are taken.

2. Security

Industrial tablets store important confidential information, such as company production, logistics, and development plans, so information security measures are essential. However, because tablets are easily portable, there is a risk of loss. To counter such risks, it is necessary to set access restrictions, thoroughly record when information is taken out of the office, install anti-virus software, and encrypt information.

3. Radio Wave Environment

Since the signal environment may be poor at outdoor sites, some industrial tablets have systems that allow users to create reports and refer to manuals, even in an offline environment.

If the system is designed to operate in an offline environment, the existing software also needs to store data locally instead of in the cloud so that it can operate in an offline environment.

4. Explosion-Proof Measures

In chemical plants and other workplaces where organic solvents are handled or where a lot of dust is generated, electronic equipment can become a source of ignition and cause serious accidents. Explosion-proof tablets that can be used in such workplaces are also available.

Like other industrial tablets, explosion-proof tablets have waterproof, dustproof, and security functions, and can be used onsite as industrial tablets.