What Is an Ultrasonic Disperser?

An ultrasonic disperser is a device that disperses substances and accelerates reactions. It is also called an ultrasonic homogenizer because it uses ultrasonic waves to homogenize substances.

Mixing substances is fundamental to processing, but some substances, such as water and oil, do not mix easily. One of the reasons why substances are difficult to mix is that their particles are of different sizes. Ultrasonic dispersers can be used to grind particles finely and align the particle sizes of substances.

In addition, compared to other milling methods, ultrasonic dispersers do not use milling media (e.g., beads) and are therefore less prone to contamination and easier to maintain. Because of these advantages, ultrasonic dispersers are used in many fields.

Uses of Ultrasonic Dispersers

Ultrasonic dispersers provide many advantages in manufacturing by homogenizing the particles of a substance. They can successfully mix substances that are difficult to mix with each other and stabilize quality.

Surfactants are used for difficult-to-mix combinations such as water and oil, but it is difficult to mix them uniformly when added alone. Ultrasonic dispersers and surfactants can be used together to mix water and oil effectively.

Ultrasonic dispersers are widely used in the food manufacturing industry and are useful for products such as mayonnaise, juice, and cream. They also contribute to the improvement of ink quality in the manufacture of printing-related products.

Principle of Ultrasonic Dispersers

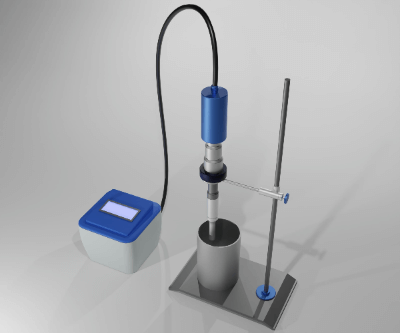

Ultrasonic dispersers consist of a transducer, an oscillator, and a horn, which irradiates ultrasonic waves into the liquid to homogenize the material. The output from the oscillator is converted into vibrations by the vibrating elements in the transducer and radiated from the horn into the liquid.

When vibrations are generated in the liquid, pressurization and depressurization are repeated, creating a vacuum bubble called cavitation. The shock wave generated when the bubble breaks generates a large flow in the liquid, and the flow brings the solidified particles into contact with each other, breaking up the particles into smaller clumps.

The characteristic feature of ultrasonic dispersers is that they do not exert an external physical impact, but rather homogenize the substance through contact between particles. Therefore, the dispersed particles are easily formed into a spherical shape, making it suitable for the final process of dispersion.

Types of Ultrasonic Dispersers

Ultrasonic dispersers are a widely used technology in a variety of fields. There are five main types: batch ultrasonic dispersers, in-line ultrasonic dispersers, hand-held ultrasonic dispersers, low-frequency ultrasonic dispersers, and high-frequency ultrasonic dispersers. By selecting the appropriate type according to application and performance, effective dispersion processing can be achieved.

1. Batch-Type Ultrasonic Disperser

A batch ultrasonic disperser is a type of equipment that processes a fixed amount of liquid in a container. A specific amount of sample can be processed at a time, making it suitable for use in laboratories and on small production lines. This type is also suitable for evaluation in the experimental or prototype stage.

2. In-Line Ultrasonic Disperser

In-line ultrasonic dispersers are a type of equipment that perform processing in a continuous flow. It is suitable for mass production or when continuous processing is required. By continuously irradiating ultrasonic waves into the flowing liquid, efficient and uniform dispersion processing is possible.

3. Hand-Held Ultrasonic Disperser

Handheld ultrasonic dispersers are small, hand-held devices. They are suitable for simple dispersion processing and for use in situations where space and containers are limited. Their portability and flexibility make them useful for research or when flexibility is required in the field.

4. Low-Frequency Ultrasonic Disperser

Low-frequency ultrasonic dispersers are devices that operate in the lower frequency range. It can effectively disperse large particles and masses. It is suitable for processing large particles into smaller ones efficiently in the fields of construction materials and ceramics.

5. High-Frequency Ultrasonic Disperser

High-frequency ultrasonic dispersers are devices that operate in the high frequency range. They are excellent for dispersing fine particles and stabilizing emulsions. They are suitable for cosmetics, pharmaceuticals, and nanotechnology fields that handle fine particles and require high dispersion performance.