What Is a Slit Nozzle?

Figure 1. What is a slit nozzle?

A slit nozzle is a fluid nozzle with a straight slit.

It is capable of jetting a uniform velocity distribution over the entire slit width. They are used for both gases and liquids.

For gases, they are often used as air blowers or air curtains. For liquids, they can be used for cleaning and cooling with water, as well as coating and surface treatment with chemicals.

As an option, a heater for hot air can be attached to the nozzle’s inlet side for hot air curtains and uniform surface heat treatment.

Uses of Slit Nozzles

Slit nozzles have various applications depending on whether the fluid inside is compressed air or water/coating liquid.

- Drainage (especially rapid drainage of plate workpieces), drying

- Cleaning of glass substrates, liquid crystal materials, etc.

- Cooling of steel plates, castings, etc.

- Humidity control of paper and cardboard

- Removal and cleaning of dust, chips, and foreign matter

- Blocking of outside air, gases, flying mist, and dust (air curtains)

- Development in the Electronics Industry

- Etching, surface treatment

- Uniform chemical coating

- Use as an air knife

- Coating, washing, and draining in the food industry

- Water removal cooling and coating in the painting process

- Dust removal and peeling of plastic film surfaces in the chemical industry

Other areas of application include electrical and electronics, vehicles and transportation, and iron and steel.

Principle of Slit Nozzles

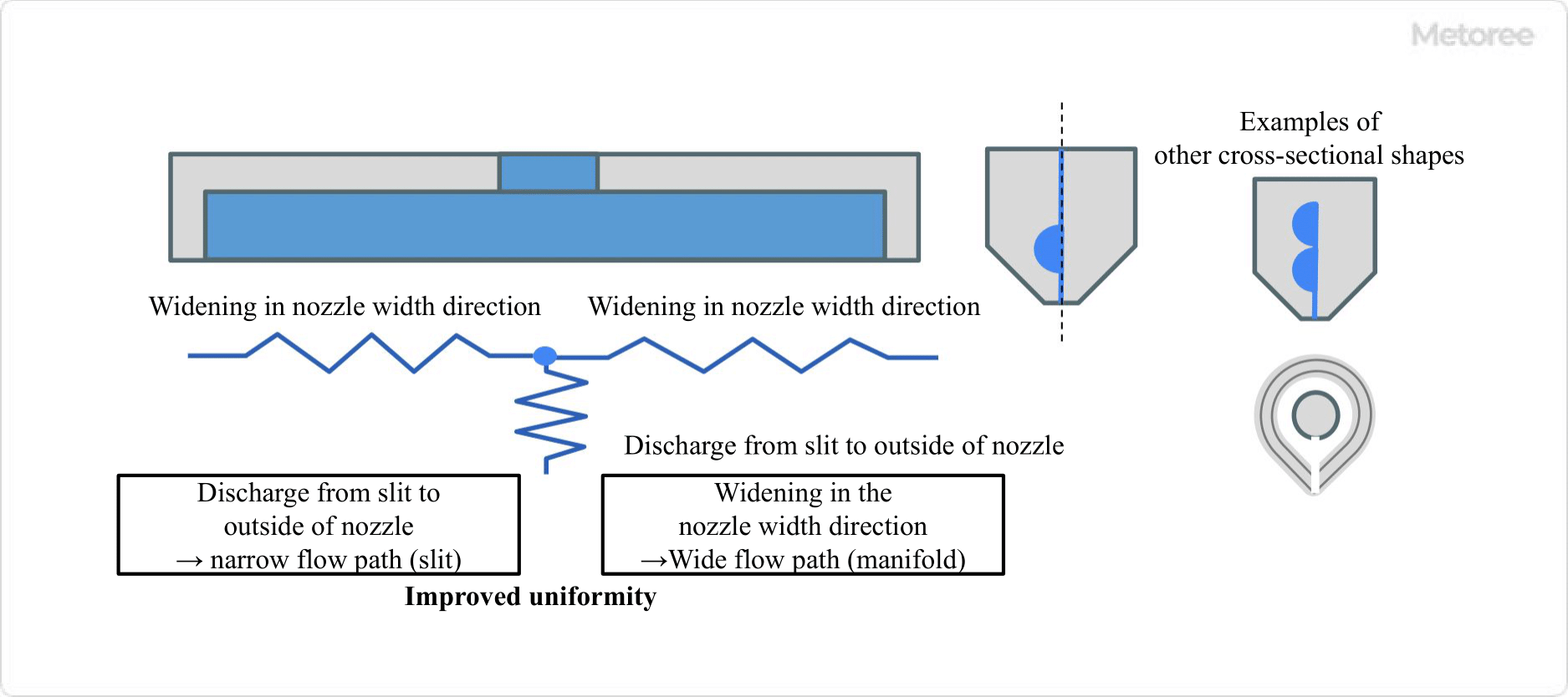

Figure 2. Principle of slit nozzle

Slit nozzles have a large pressure drop in the direction of blowout due to the narrow slit-like holes, so the manifold increases uniformity in the width direction, which results in uniform discharge in the width direction. Instead, especially with pressurized air nozzles, the large pressure loss results in high energy consumption and a large drop in discharge pressure.

When used as a liquid nozzle, this problem can be solved by using a metering pump with sufficient supply pressure. However, in the case of liquid, it is necessary to design the Slit nozzle so that it will not be deformed by the high pressure.

Features of Slit Nozzles

Slit nozzles are designed to ensure uniform flow and velocity distribution of the fluid passing through them.

- Slit Width: Approx. 05 to 1.6 mm

- Slit Length: About 50 to 4000 mm

Both types are available in a wide range of lineups and can be selected according to the size of the target component and its application. There is also a type in which the slit width is not fixed but can be adjusted according to the workpiece and air volume. The fixed type is easier to maintain, but the adjustable type can also be selected depending on the application.

A wide variety of materials are available, including stainless steel, PVC, aluminum, titanium, and PPS resin. Some are designed to be used exclusively with blower air, while others can generate a liquid film if the material is chemically resistant.

Uniform thin film atomization is possible, which helps reduce the cost of chemicals and deionized water. The spray direction can be up, down, or sideways, and if the product size is small, it can also be used in narrow gaps.

How to Choose a Slit Nozzle

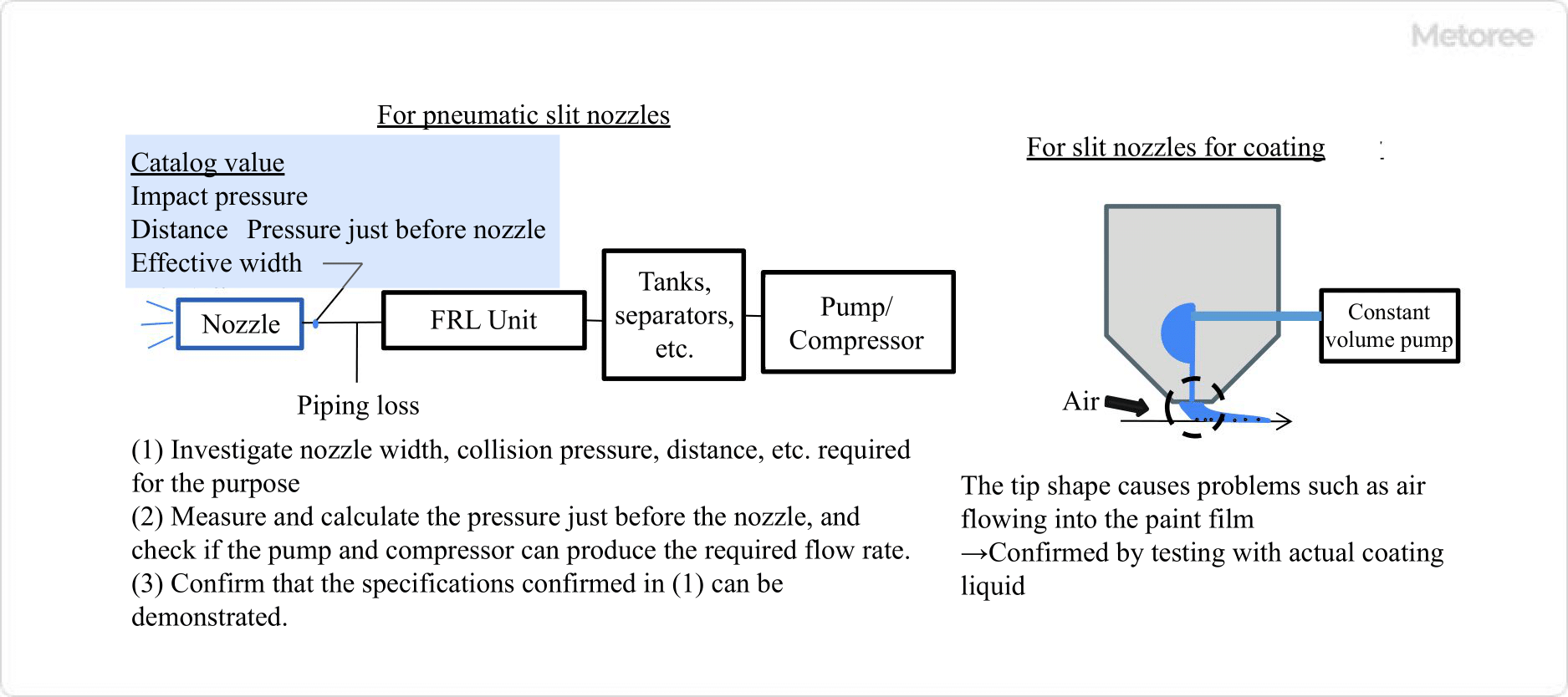

Figure 3. Selection of slit nozzle

Slit nozzles are used for a variety of air, gas, water, and chemicals. They are also used for a wide variety of applications, including drying, cooling, cleaning, air curtains, and application. Slit nozzles can be used for multiple applications, but the performance required is different, for example, air pressure rather than uniformity for cleaning applications, and uniformity for application, so it is best to select the slit nozzle that is most optimally designed for that application.

Slit nozzles sold by various companies are designed to some extent in consideration of the intended use, so it is important to confirm the design. For slit nozzles that use pressurized air or gas as the working fluid, specifications such as impact pressure and noise level are listed.

For slit nozzles, the width and length of the slit and the material are the most important basic specifications. Once these are determined, other important points include maintainability, whether the slit width and length need to be adjustable, and ease of installation.

In addition, the shape of the tip of the slit nozzle used for coating may affect whether air entrainment or living phenomenon occurs, so it is recommended to test the most suitable one for the viscosity of the coating liquid.