What Is a Draft Chamber?

A draft chamber is a type of local exhaust ventilation system used when handling hazardous substances that may affect the human body in chemical or biological experiments.

A draft chamber is a type of local exhaust ventilation system used when handling hazardous substances that may affect the human body in chemical or biological experiments.

There are two main types of local exhaust ventilation systems: enclosed types, which cover the hazardous materials, and external types, which are open and have a hood placed next to the hazardous materials. Draft chambers are classified as enclosed local exhaust ventilators.

Among the enclosed types, there are four types: cover type, glove box type, draft chamber type, and building booth type.

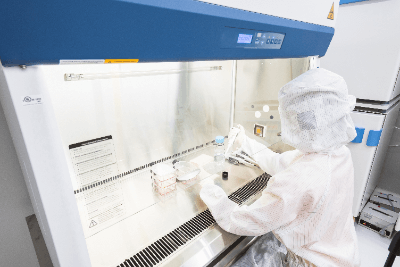

The draft chamber type is characterized by a wide working table and easy operation through the large up-and-down (or left-and-right) sliding door that opens widely in front.

Uses of Draft Chambers

Businesses will be obligated to install draft chambers (or appropriate local exhaust ventilation) to protect the health and safety of workers.

Place the hazardous material in the draft chamber, and the operator should open the front sliding door slightly and work only with hands inside.

Never put your head inside the draft chamber at this time. Correct use of the draft chamber will not only prevent inhalation of vaporized or dispersed hazardous substances, but will also protect the safety of the operator in the event of an explosion.

Principle of Draft Chambers

Draft chambers do more than simply provide ventilation. The air that passes through the exhaust duct goes through a scrubber, which removes harmful substances, and is then exhausted outdoors.

Conventional constant-air-volume draft chambers exhaust a fixed amount of air regardless of whether the door is opened or closed. Therefore, without proper air supply, the balance between exhaust air and air supply will be upset, and the room in which the draft chamber is operating will not be able to maintain a negative pressure.

In addition, the constant air volume system exhausts a large amount of conditioned air to the outside, which has been considered a problem from the standpoint of energy conservation.

The variable air volume (VAV) system compensates for these shortcomings.

The variable air volume system automatically calculates the necessary exhaust air volume according to the degree to which the door is opened and closed, thereby reducing the wasteful exhaust of conditioned air.

Role of the Scrubber

Since the air in the draft contains volatilized solvents, reagents, and fine particles, it cannot be discharged directly into the standby area. Therefore, it is passed through a facility called a scrubber to trap harmful substances contained in the exhaust gas. Scrubbers are classified into dry and wet types depending on the trapping method.

- Dry Scrubber

Activated carbon and non-woven filters are installed on the exhaust gas path to collect dust and volatile organic solvents. By changing the type of filter, the system can handle a variety of gases.

- Wet Scrubber

Alkaline cleaning water is sprayed from a shower nozzle to dissolve and neutralize water-soluble gases. The ability to neutralize acidic vapors is an advantage not found in the dry type, but a disadvantage is the inability to collect non-water soluble vapors.

In addition, periodic voluntary inspections of the draft should also check for clogged or damaged scrubbers. During the inspections, protective equipment should be worn on the assumption that the filters and cleaning water contain hazardous substances.

Simple Draft Chamber

There are also simple draft chambers that can be placed on a tabletop. The transparent box-shaped body is equipped with an air blower and exhaust duct hose, and some models are also equipped with a filter for exhaust gas treatment. When in use, it is placed on a horizontal table, and the exhaust hose is connected to a local exhaust system to blow air.

It can be used as an alternative when a draft chamber cannot be installed, but since it is only a simple device, the following points should be noted.

- Due to the small working space, the reagent bottles and beakers may be knocked over by hands during operation, resulting in splashing of the contents. Care should be taken to keep only the minimum amount of reagents in the box.

- Gas or vapor may remain in the exhaust duct hose and may be blown out and aspirated when cleaning up. Local exhaust air should be kept running for a while after use to fully displace the air in the hose.

- Exhaust filters are also simple and may not be able to handle large amounts of gas. Exhaust should be treated after passing through a scrubber, or restrictions should be set so that only small amounts of reagents are handled.

Other Draft Chamber Information

1. Mandatory Self-Inspection of Draft Chambers

Business operators who install draft chambers must conduct a voluntary periodic inspection once every year or less.

The contents of the inspection include:

- Whether and to what extent hoods, ducts, and fans are worn, corroded, dented, or otherwise damaged.

- Dust accumulation in ducts and exhaust fans

- Looseness at duct connections

- Working condition of the belt connecting the electric motor to the fan

- Intake and exhaust capacity

Other items necessary to maintain performance are listed below. Employers are required to conduct voluntary inspections to satisfy the above and record the results on an inspection sheet. In addition, this inspection sheet must be kept for three years, so please keep this in mind when introducing draft chambers.

If an abnormality occurs, the manufacturer should be consulted to finalize a countermeasure policy. If repairs are necessary, the results should be preserved as well.

2. Anemometer for Draft Chamber Inspection

One of the inspection items is to check the exhaust capacity. This is to confirm that the draft chamber is being properly vented.

- At least 0.4 m/s in the scope of application

- For particulate exhaust under the same law, 1.0 m/s or more

must be satisfied.

Anemometers are used to check these exhaust capabilities.

There are different types of anemometers, such as hot-wire anemometers and vane anemometers, but there are no regulations, so any one of them can be selected at will.

However, the question is whether the anemometer is measuring the correct value. If the anemometer used for the inspection is not functioning at all, the inspection results will contain false information. Please keep in mind to not forget to calibrate the anemometer itself.