What Is a Galvo Laser?

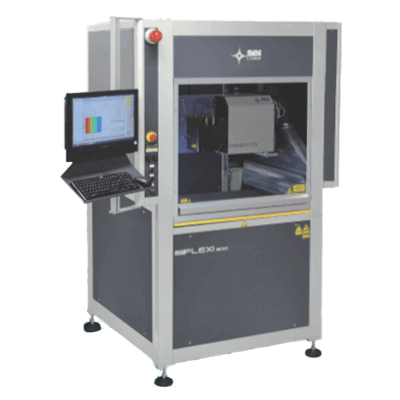

Galvo lasers are a type of laser processing machine.

These machines, also known as laser cutters or laser engraving machines, can cut, engrave, and perform various other processes on materials by emitting laser beams. There are two main types: flatbed and galvano.

Uses of Galvo Lasers

Galvo lasers excel in cutting thin materials such as paper, film, and fabrics at high speeds, making them ideal for various industrial applications, including:

- Printing and paper industries.

- Paper containers and packaging.

- Flexible packaging and food packaging.

- Seals and labels.

- Apparel and textiles.

- Furniture, fittings, and building materials.

Principle of Galvo Lasers

Galvo lasers function by emitting a laser beam from a fixed head controlled by mirrors. Unlike flatbeds, where the head moves in the XY axis, galvo lasers have a more limited processing area and material thickness capacity but are faster in processing.

For processing a variety of materials or thicker items, flatbed lasers are more suitable. Galvo lasers are recommended for cutting and engraving thinner materials like paper, film, and fabrics.

The key components of galvo lasers are as follows.

1. Mirror

The mirror reflects the laser beam. Its size and coating depend on the laser’s specifications, affecting the required acceleration torque and current.

2. Scanner

The scanner, the primary driver for the mirror, controls its angle and position. The galvanometer scanner motor oscillates at a limited angle for precise control and durability, enabling rapid, high-torque movements.

3. Control Driver

The control driver manages the information from the mirror and scanner, controlling the mirror angle through the galvanometer scanner. It functions as the command center for the laser’s operation.

Materials That Can Be Processed With Galvo Lasers

Galvo lasers can process a diverse range of materials, including:

- Acrylic resin.

- Wood.

- Paper.

- Fabrics and fiber.

- Leather.

- Metals.

- Plastics and resin.

- Stone.

They are particularly effective for high-speed cutting of thin materials like paper, film, plastic, and resin, as well as wood boards, fabrics, fibers, and textiles. Additionally, they can perform surface engraving on a wide range of materials.