What Is an Articulated Robot?

An articulated robot is a robot with multiple joints in their arms.

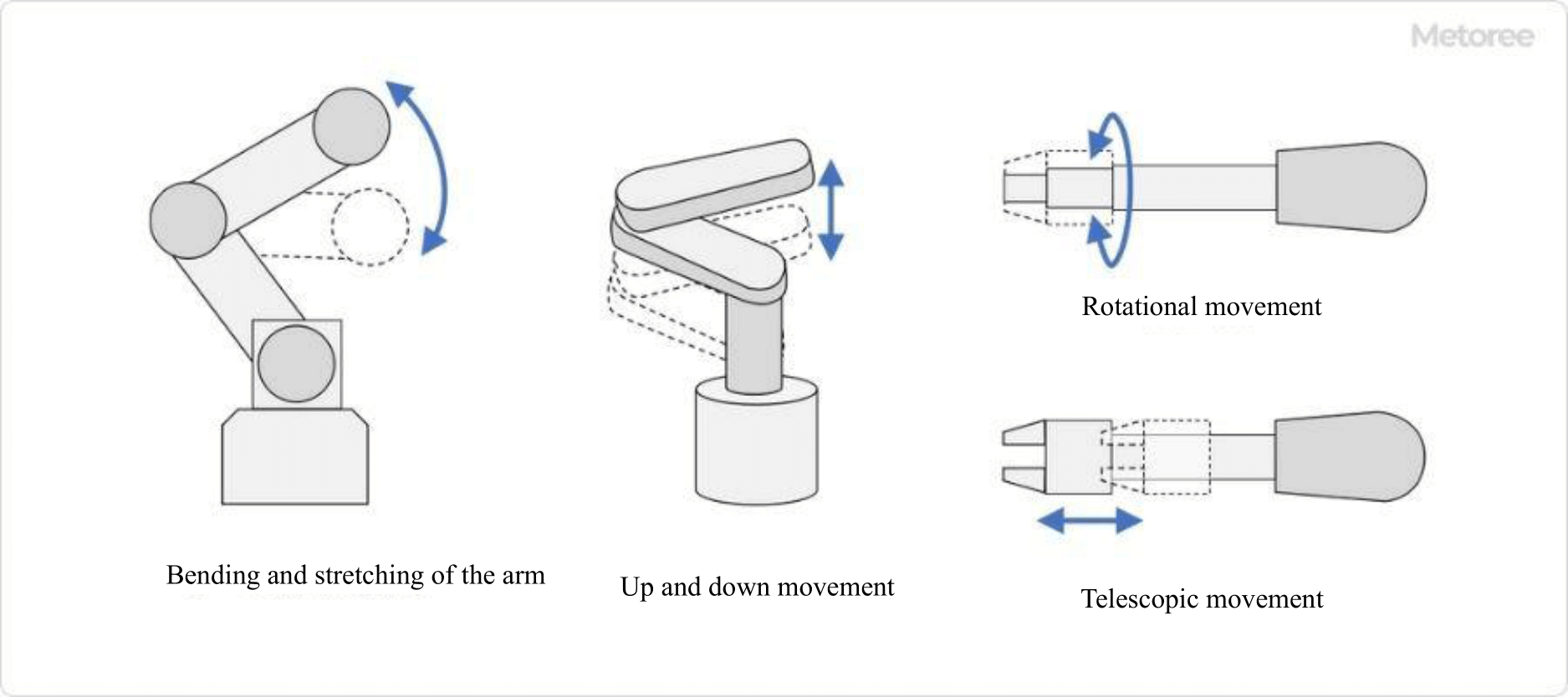

The joints perform the following actions:

- Bending and stretching of the arm

- Vertical movement

- Rotation

- Extension and contraction

Articulated robots have joints that resemble human movements, such as bending and stretching, as well as linear joints unique to articulated robots, such as extension and contraction. This enables them to perform various tasks in place of humans.

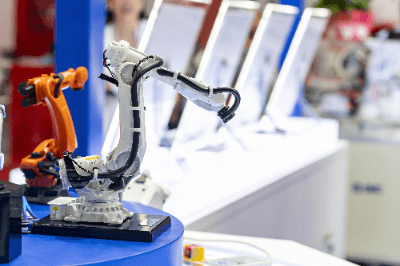

Figure 1. Joint movement of articulated robots

The main types of articulated robots are vertically articulated robots and horizontally articulated robots. Each has a different arm and joint structure, and each specializes in different tasks.

Uses of Articulated Robots

Articulated robots are mainly used to perform the following tasks in place of humans:

- Heavy-duty work such as lifting heavy loads

- Work that requires repetition of the same task for a long period of time

- Work that requires skilled workmanship

- Inspection work using sensors and cameras

Unlike humans, robots do not get tired and can accurately perform the same task for a long time. Leaving simple tasks to robots allows humans to engage in value-added processes, thereby increasing factory productivity.

In addition, the robot’s ability to reproduce precise movements allows it to accurately trace the movements of skilled workers. This is expected to preserve skill level by transferring the skills of veteran technicians who are about to retire to the robot. With the recent development of AI technology, sensors and cameras can be attached to articulated robots to automate inspections.

Principles of Articulated Robots

Links and joints in a robot correspond to human bones and joints, respectively. The joints are rotational axes and linear motion mechanisms that increase the range of motion of the links, allowing the robot to perform tasks similar to those performed by humans.

Early robots were driven by hydraulic power, but today, motor-driven robots are the norm. Electronic control enables more precise movements.

Other Information on Articulated Robots

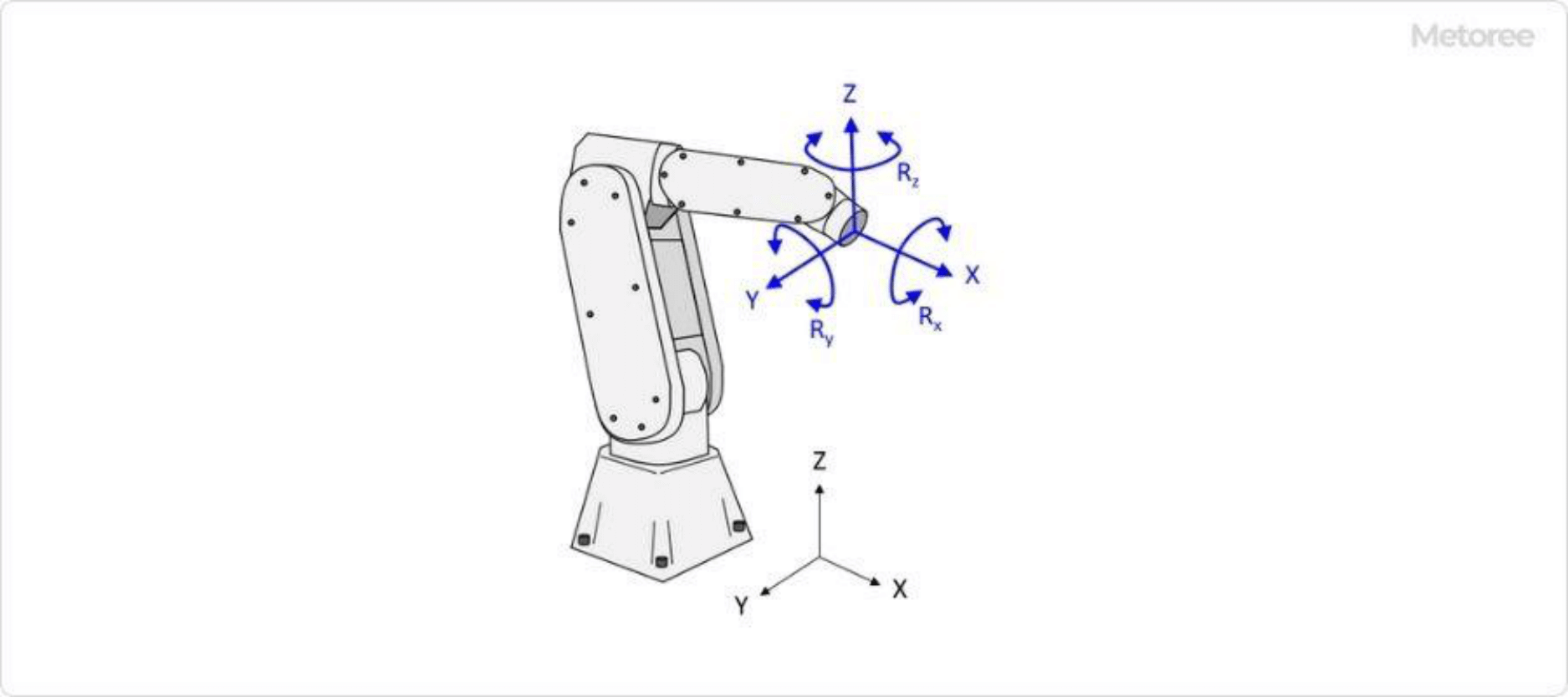

1. What Are Vertically Articulated Robots?

Vertically articulated robots are robots whose joints are oriented to move the arm vertically. Vertically articulated robots generally have six axes and can perform horizontal and vertical movements such as X, Y, and Z, as well as rotational movements such as Rx, Ry, and Rz.

Vertically articulated robots are capable of movements similar to those of the human arm.

- Work that requires an oblique approach, such as welding, painting, etc.

- Workpiece transfer work in locations with complex entry paths

and other tasks that require a diagonal approach, such as welding and painting.

Figure 2. Vertical articulated robot

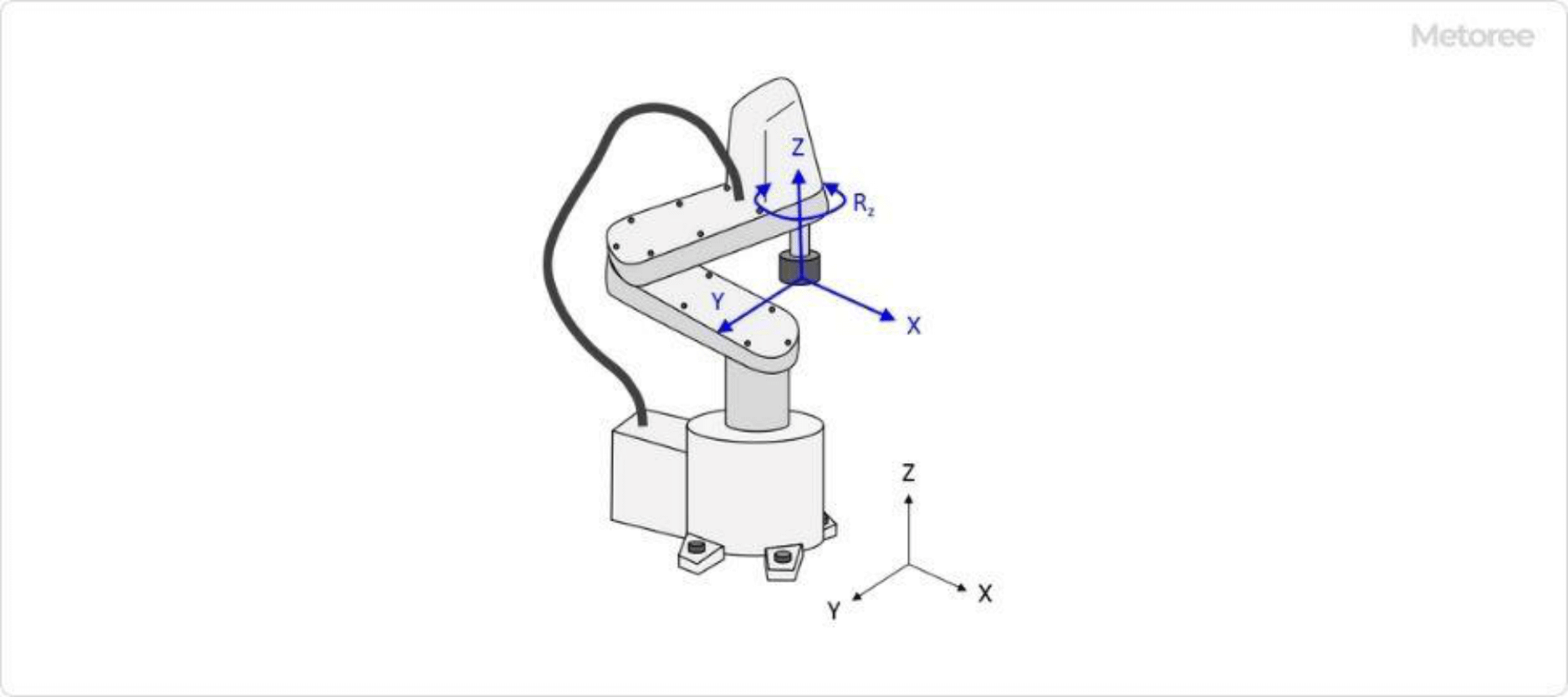

2. What Are Horizontally Articulated Robots?

Horizontally articulated robots are equipped with three rotational axes that operate mainly in the horizontal direction. They are often referred to as SCARA robots. In addition to the horizontal rotational axes, products with one additional axis for vertical motion are common.

Horizontally articulated robots have the following advantages over vertically articulated robots

- Quick movement in the plane (X, Y, and Rz directions)

- Higher rigidity in the vertical direction

- Low cost

The following are some of the tasks that take advantage of the benefits of Horizontally Articulated Robots.

- Picking workpieces from a conveyor belt and packing them into boxes

- Vertical screw tightening work

- Aligning workpieces in a plane

Horizontally articulated robots and horizontally articulated robots are the same type of articulated robot but have different characteristics, so they should be used according to the work you want to perform.

Figure 3. Horizontally articulated robot

3. Low-Cost Articulated Robots

Articulated robots are expensive, traditionally costing tens of thousands of dollars and more, but in recent years, low-cost articulated robots have become available from a variety of manufacturers. These robots are mainly used for electronic construction and programming learning.

Inexpensive robots can be purchased for as little as several hundred dollars, but because they use inexpensive joint structures and motors, their positioning accuracy, repetitive stop position accuracy, operating speed, and durability are much lower. When purchasing a robot, it is necessary to carefully judge whether or not it can withstand practical use.