What Is a Desktop Robotic Machine?

A desktop robotic machine is a compact robot designed to be placed on a desk. These machines are commonly used in factory automation (FA) to replicate tasks performed by workers or assist salespeople in sales applications. Depending on the task, robots may be uniquely developed for specific workpieces or assembled from generic products offered by robot manufacturers. The versatility of these machines is enhanced by the interchangeable end-effectors, allowing them to be adapted for various applications.

Uses of Desktop Robotic Machines

Desktop robotic machines are primarily used in factory automation settings, such as in the manufacturing of automobiles and electrical equipment. They are also employed in processes like resin application, screw tightening, board cutting, and inspection. Choosing the right type of desktop robotic machine is essential, depending on the intended use and the operating environment.

Principle of Desktop Robotic Machines

A desktop robotic machine typically comprises an end-effector for task execution, a moving part like an arm to maneuver the end-effector, and a control unit for overall robot management. The end effector can perform a variety of tasks such as welding, cutting, and assembly, adapting to different application requirements.

For instance, in a production line of automotive drive motors, a desktop robotic machine may follow these steps:

- Material arrives at the processing station.

- An identification sensor checks the material to be processed.

- Based on the sensor’s detection, the machine is instructed to start assembly.

- The end-effector jig is replaced for the assembly operation.

Due to its versatility in applications like assembly and inspection, desktop robotic machines are particularly suitable for cell production sites with high-mix, low-volume production.

Types of Desktop Robotic Machines

Desktop robotic machines can be categorized into several types:

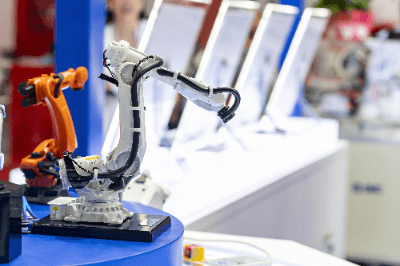

1. Vertically Articulated Robots

These robots have a structure akin to a human arm, generally consisting of 4 to 6 axes, allowing free movement in three-dimensional space.

2. Cartesian Coordinate Robots

Cartesian coordinate robots feature a simple structure with a single-axis linear motion unit, often comprising three axes (XYZ).

3. Horizontal Articulated Robots

These robots move their hands (end-effectors) horizontally, usually with 4 axes, including 3 for horizontal motion and 1 for vertical movement.

Other variants include dual-arm models and those designed for specific tasks like welding or cutting with a single arm, or multifaceted tasks like assembly with two arms.

Other Information on Desktop Robotic Machines

1. Safety Measures for Desktop Robotic Machines

Larger robots, such as those with an output power of 80 W or more, typically require safety fences to separate the operator’s work area from the robot’s operating zone. However, recent regulations have relaxed this requirement if safety measures like slowing down or stopping the robot when a person approaches are implemented. Desktop robotic machines, often designed for human collaboration and usually having an output of 80 W or less, don’t necessitate these fences. However, when performing tasks like application work with needles attached to the arm, it’s crucial to use distance sensors and cameras to ensure human safety.

2. Application Example of Desktop Robotic Machine (Pen Plotter)

A pen plotter is a device that transcribes characters from a PC onto paper using a pen. Initially used in mechanical engineering for drawing transcription, pen plotters can be configured with SCARA robots or vertically articulated desktop robotic machines. The latter, with their high movement freedom and rotational capabilities, can replicate handwriting more closely than traditional models.