What Is a CAD System?

A CAD (Computer Aided Design) system is a design method or software that allows design and drafting to be done on a computer, whereas they were originally done by hand on paper.

CAD was developed by American computer scientists in the 1960s and was initially used for aircraft design. Later, it spread to industrial fields such as architecture and automobiles, and is now also used in the apparel industry.

There are two types of CAD systems: 2D CAD systems, which represents drawings in two dimensions, and 3D CAD system, which represents drawings in three dimensions.

There are also two types of CAD systems: general-purpose CAD, which can be used in any field, and specialized CAD, which has functions specific to a particular field, such as architecture, automobiles, and electrical engineering.

A Computer Aided Manufacturing (CAM) system is a tool similar to CAD that creates control programs for manufacturing machines based on CAD design information, and Computer Aided Engineering (CAE) system is a tool that simulates whether a product designed with CAD satisfies target performance and evaluation requirements. Both are used in conjunction with CAD systems.

Uses of CAD Systems

CAD Systems are used in a variety of industries that have a design process as part of their business.

The main uses are as follows:

1. Drawing Creation

CAD systems are used to create drawings for buildings, automotive parts, and any other area where dimensions, shapes, and their ranges need to be specified.

Sharing and editing data with clients and business partners can also help shorten architectural design turnaround time and speed up parts development.

2. Design

CAD Systems can be used not only for structural design, but also for automobile, furniture, and interior design. By using CAD systems, the work conventionally done by designers with sketches can be conveyed in three dimensions.

Unlike sketches, the concept can be conveyed more easily by viewing it from various angles and rotating it on the system screen.

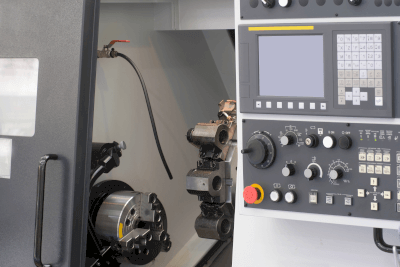

3. Creation of Data for Machine Tools

NC machining is a method of machining metals, wood, and plastics, in which a rotating blade is applied to the workpiece to create the desired shape.

4. Structural Analysis and Simulation

CAD Systems can not only design the dimensions and design of a structure, but also simulate its behavior when force is applied. For example, when designing a chair of a certain shape, it is possible to predict by analysis how much force will be applied to the legs when a load is applied to the seating surface, and whether the legs will be deformed or damaged.

CAE (Computer Aided Engineering) software is used for the analysis.

Principles of CAD Systems

CAD Systems can be implemented more speedily than the work done by hand on paper. It is possible to make the thickness of lines and handwritten text uniform, which tends to cause errors among workers. Drawing corrections can also be made by pinpointing and changing only the relevant areas.

By saving the history of design data, it is possible to go back to previous data and redo the design. In addition, by importing past drawing data, common tasks for similar designs can be reduced, thereby improving efficiency.

In addition, paper-based blueprints are at risk of tearing and ink fading, but CAD system data is free of such risks. Because it is easy to manage, CAD data can be instantly shared with people who are physically separated from each other via e-mail or other means.

Types of CAD Systems

There are two types of CAD systems: 2D CAD and 3D CAD.

1. 2D CAD System

CAD Systems use a computer to create the equivalent of conventional paper drawings: front, plan, and side views based on trigonometry. The drawings themselves are no different from those of the hand-drawn era, but designing on a computer has dramatically improved work efficiency.

2. 3D CAD Systems

3D CAD Systems are used to design and produce drawings in three dimensions itself. It can be viewed as a three-dimensional drawing from any viewpoint, which has the advantage of making it easy to grasp the shape of even complex designs.

There are two methods of designing with CAD systems: the direct modeling method, in which the shape information of a three-dimensional object is directly modified, and the parametric method, in which a three-dimensional model is constructed by specifying parameters such as dimensions and constraint conditions.