What Is Numerical Control (NC)?

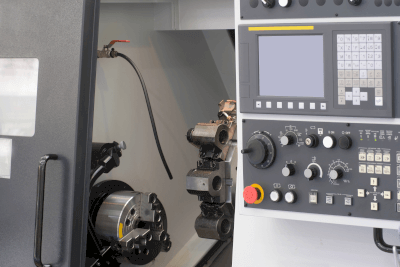

Numerical control (NC) is a technology that directs the operations of machine tools using programmed numerical data. Developed in the 1950s in the United States and later adopted in Japan, NC transformed manufacturing by automating the machining process, leading to precise and efficient production.

Uses of Numerical Controls (NC)

NC is integral to the manufacturing of precision components across various industries, including electronics, interior design, medical devices, and semiconductors. Its applications range from creating intricate parts for electronics to fabricating complex components for medical devices.

Principle of Numerical Controls (NC)

The core of NC technology is the NC program, which outlines tool paths, machining sequences, spindle speeds, and other operational parameters. This program is executed by a servo mechanism that controls the machine’s movements, ensuring accurate and efficient machining of the workpiece.

Other information on Numerical Controls (NC)

- NC Program: This can be manually entered by an operator or generated by CAM (Computer-Aided Manufacturing) software. It dictates the tool’s trajectory and operational settings, such as speed and feed rate, leveraging servo motors for precise execution.

- Coordinate System: Utilizes a Cartesian coordinate system (X, Y, Z) to define the tool paths and workpiece positioning. The system includes machine coordinates (inherent to the machine), workpiece coordinates (origin set on the workpiece), and relative coordinates (adjustable by the operator).

- Tool Selection: The choice of end mills and other cutting tools is critical for NC machining, influencing the efficiency and quality of the process.

- Machining Stages and Conditions: Planning for roughing and finishing stages is essential, with specific considerations for spindle rotation speed and feed rate based on the material and machining strategy.

With advancements in computing, NC has evolved into CNC (computerized numerical control), becoming a standard in modern manufacturing for its precision, repeatability, and efficiency.