What Is a Blow Air Gun?

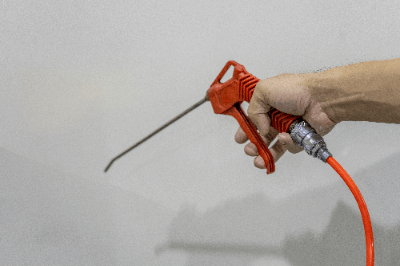

A blow air gun is a tool that uses compressed air to blow dust and dirt away from the surface of objects.

Typically utilized in various applications, including industrial and automotive maintenance, and household cleaning, examples include air compressors and receiver tanks that generate compressed air. Owing to their use of compressed air, blow air guns can effectively clean even the smallest crevices and areas of complex shape.

They allow for efficient removal of dirt and dust in areas challenging to clean manually, enabling a quicker cleaning process compared to traditional methods.

However, due to the use of high-pressure air, it is crucial to exercise caution to ensure safety. Wearing appropriate protective gear, such as safety glasses, is essential, as direct exposure to high-pressure air can result in injuries to the eyes or skin.

Uses of Blow Air Guns

Thanks to their efficient cleaning capabilities and versatile usage, blow air guns find application in various settings:

1. Automotive Maintenance

Useful for cleaning engine crevices, parts around wheels, brake discs, etc., blow air guns enhance maintenance efficiency and cooling effectiveness. Cleaning these parts is also vital for ensuring safe operation and optimal brake performance.

2. Factories

In manufacturing environments, the cleanliness of machinery and equipment is pivotal for maintaining production quality and safety. Blow air guns play a crucial role in dust removal from machine parts and crevices, thereby preserving precise operation and minimizing the risk of malfunctions and defects.

3. Metal Processing

During the cutting and welding processes in metalworking, metal scraps and chips are produced. Blow air guns are frequently employed to clear these byproducts, preventing debris accumulation, preserving cutting accuracy, and maintaining a safe working environment.

4. Information and Communications

Commonly used for cleaning personal computers and keyboards, blow air guns help remove dust and particles from key gaps and internal fans, ensuring devices operate normally and extend their lifespan. However, air dusters are preferred for smaller-scale cleaning tasks.

Principle of Blow Air Guns

A blow air gun operates by utilizing compressed air to clear dust and dirt from object surfaces. It is comprised of a main body, a nozzle, and an air connection port.

1. Main Body

The main body includes a handle and grip, along with a casing that encloses the internal mechanism. It houses the trigger and operation buttons, serving as the user interface for the blow air gun.

2. Nozzle

Designed to direct compressed air at high velocities, the nozzle’s shape and size are tailored to specific applications and may be interchangeable. Certain models are equipped with air filters to enhance the quality of the air output.

3. Connection Port

Engineered for attachment to a compressed air supply, the connection port on the blow air gun’s body links to the air source via a hose or other means.

Types of Blow Air Guns

There are many different types of blow air guns, depending on their application and shape. The following are common types of blow air guns:

1. Jet Type

Specializing in powerful air delivery, this model is designed for high-impact cleaning and is used alongside high-pressure air compressors.

2. Long Type

Featuring a long, narrow nozzle, this model excels in reaching difficult spaces, with many versions offering telescopic functionality.

3. Flat Type

With a broad nozzle, this model is ideal for cleaning large, flat surfaces efficiently.

Additionally, the versatility of blow air guns is enhanced by the availability of multiple nozzle attachments, catering to varied cleaning needs and applications, including large-area dust blowing and air curtain creation.