What Is an Extension Spring?

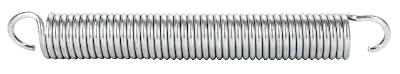

An extension spring, also known as a tensile spring or pull spring, is a type of spring that primarily expands and contracts when subjected to a pulling force.

It is created by coiling long wires into a spiral shape and is commonly used for various applications, ranking second only to compression coil springs. Due to their tightly wound structure with no gaps between coils, they can generate substantial pulling force in a relatively confined space.

This capability enables the transmission of significant forces within limited spaces and allows for customization by adjusting wire thickness and coil diameter to suit different requirements.

However, it’s essential to note that while extension springs excel at responding to pulling forces, they have limited resistance when compressed. It’s crucial to use them in the correct orientation to prevent deformation or breakage. Additionally, considering material properties and elastic limits is vital.

Applications of Extension Coil Springs

Extension coil springs find use in various applications, leveraging their robust tensile strength. The following are common applications of extension coil springs.

1. Motorcycles and Bicycles

Motorcycle and bicycle side stands are employed to stabilize the vehicle while parked. Some side stands incorporate mechanisms for retracting them when not in use, often facilitated by extension springs.

2. Household Products

Extension springs are widely used in household appliances and furniture drawers. They store energy when doors and drawers are closed, ensuring smooth operation. Additionally, they play a vital role in the mechanisms of sofas and beds, enabling reclining and unfolding movements.

3. Sports Equipment and Toys

In sports and fitness equipment, extension springs serve to control specific functions, frequently found in the adjustable parts of training equipment or the moving components of sports gear. Examples include expanders used in training equipment.

They are also employed in the moving parts of toys and model applications. You can often find them in the deployment mechanisms of airplane and vehicle models.

Principle of Extension Spring

The principle governing extension springs is based on the elastic deformation property resulting from the spiral winding of wire. It exhibits a response to pulling forces, with elastic deformation and Hooke’s law as key principles. When an external pulling force is applied to an extension spring, the wire elongates and deforms.

This deformation is temporary, and upon removal of the external force, the spring attempts to return to its original shape, following the principles of elastic deformation as defined by Hooke’s law.

Hooke’s law states that the force exerted on a spring is directly proportional to its displacement. By multiplying the displacement by the spring constant, one can determine the stored force. Extension springs can repeatedly undergo elastic deformation as long as they remain within the elastic limit of the material.

However, exceeding the elastic limit can result in permanent deformation or fracture. Therefore, when selecting and designing materials, it’s crucial to consider the elastic limit appropriately.

How to Select Extension Coil Springs

Several factors must be considered when choosing extension coil springs.

1. Material

The choice of material for extension springs significantly impacts their strength and durability. Common materials include steel and stainless steel. Material selection should align with the expected load and environmental conditions.

2. Spring Constant

The spring constant, which relates displacement to force, plays a pivotal role. A higher spring constant results in greater force for the same displacement. Thus, it’s essential to select an appropriate spring constant considering the required tension and displacement for your application.

3. Tip Shape

The shape of the extension spring’s tip influences installation and application. Hook-shaped tips are easier to install, while ball-shaped or other configurations may be suitable for specific applications. When choosing a tip shape, consider the mounting method and its interaction with the components involved.

4. Free Length

The free length refers to the spring’s length in an unloaded state. As the required spring length varies depending on the application, design dimensions, and available space for installation, it’s important to choose an appropriate free length to avoid excessive compression or extension.