What Is a One-Touch Clamp?

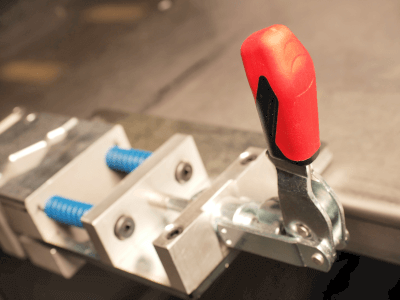

A one-touch clamp is a type of tool-less clamp that can be easily engaged and disengaged by operating a lever. This design not only reduces the time required for clamping but also eliminates the need for tools such as wrenches, thereby improving productivity and workability.

A one-touch clamp is a type of tool-less clamp that can be easily engaged and disengaged by operating a lever. This design not only reduces the time required for clamping but also eliminates the need for tools such as wrenches, thereby improving productivity and workability.

Compared to automated hydraulic or pneumatic clamps, one-touch clamps significantly reduce production costs and the burden of daily maintenance, such as addressing oil leaks.

Uses of One-Touch Clamps

One-touch clamps are commonly used in situations requiring frequent changes or securing of workpieces. They are particularly useful for clamping workpieces during machining processes or holding them steady with one hand. This is essential for operations in machining centers where the workpiece must be firmly held in place or pressed against a positioning pin for precise alignment. They are also advantageous in tight spaces where tool access is difficult.

Principles of One-Touch Clamps

These clamps allow workpieces to be secured easily and consistently with a simple lever rotation, eliminating the need for tools. The design enables the operator to hold the workpiece with one hand while securing it with the other, ensuring stability. Repeated engagement and release, even with considerable force, do not pose a risk of tampering or damage.

Variations include downward push type for top-down clamping, sideways push type for lateral hold, retract type for downward pulling, and push type for extending the shaft. Options are available in lever rotation direction, clamping direction, and force. Levers with torque adjustment are also available to minimize variation in clamping force by different operators and ensure consistent force application.

The clamping force required is considerably less than that of hydraulic or pneumatic clamps, making it suitable for confined spaces. One-touch clamps strike an optimal balance between workability and cost, positioning themselves between tool-operated and automated solutions.