What Is a Urea SCR?

SCR is an abbreviation that can refer to both “selective catalytic reduction” and “silicon -controlled rectifier.”

When we talk about urea SCR, we are primarily referring to selective catalytic reduction (SCR). As of 2022, this method predominantly employs an aqueous urea solution, hence the term “urea SCR.”

Silicon controlled rectifiers are devices with switching characteristics and a three-terminal, four-layer structure used in power control circuits.

In the following sections, selective catalytic reduction and denitration (SCR) will be abbreviated as the SCR method.

Uses of Urea SCRs

As of 2022, urea SCR is utilized in exhaust gas treatment for automobiles, ships, and thermal power plants. However, back in 1989, it was still in the research stage for diesel vehicles, with attempts made to apply this method to diesel vehicles.

It was not until 2004 that practical application in automobiles was achieved. In the same year, Nissan Diesel (now UD Trucks) became the world’s first company to incorporate urea SCRs, named FLENDS, into automobiles and put them into practical use.

Future demand for urea-SCR systems is expected to grow, partly due to diesel emission regulations that came into effect on October 1, 2003 (with standards based on the new regulations implemented on April 1, 2006).

Principles of Urea SCRs

In urea SCRs, exhaust gas initially passes through an oxidation catalyst, where NO is converted to NO2. During this process, CO and HC are also reduced. Next, an aqueous urea solution is injected into the exhaust gas, before the SCR catalyst, where the NH3 produced by urea hydrolysis serves as a reducing agent. NH3 reacts with NOx on the SCR catalyst, converting NOx into harmless N2. Finally, NH3 is further reduced by passing through an oxidation catalyst. This oxidation catalyst is used for ammonia slip control, which prevents the emission of ammonia into the atmosphere.

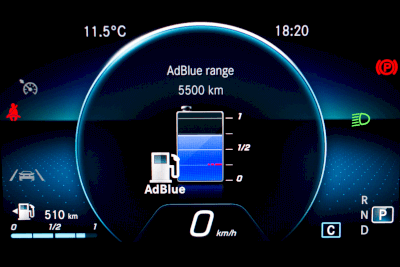

High-quality aqueous urea solutions are crucial for urea SCRs, as impurities can lead to deposits and disrupt the reduction process. An example of a high-quality aqueous urea solution is AdBlue, a registered trademark of the German Association of the Automotive Industry (VDA). The logistics industry was significantly impacted because diesel vehicles, in general, cannot restart without a continuous supply of aqueous urea solution.

Additionally, the production of urea water relies on urea as a raw material, synthesized from gaseous ammonia and carbon dioxide under high temperature and pressure conditions. In 2020, the Tokyo Institute of Technology announced a successful synthesis of urea from ammonia (carbonates) found in wastewater. The University of Tokyo also reported successful urea synthesis from ammonia (carbonates) in wastewater. Furthermore, urea has gained attention as a stable hydrogen carrier. This research was published on February 18, 2020, in the Nature Research scientific journal Scientific Reports under the title “Organic bases catalyze the synthesis of urea from ammonium salts derived from recovered environmental ammonia.”

Considering the above, the stable supply of urea water is a future concern for urea SCRs. However, ongoing research and development efforts are expected to establish the necessary infrastructure in due course.