What Is a Manifold Block?

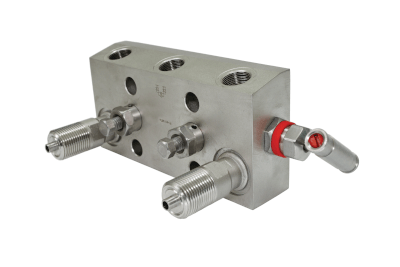

A manifold block is a metal component that houses a circuit for fluid flow.

A manifold block is a metal component that houses a circuit for fluid flow.

This component is advantageous because it is smaller, lighter, and requires less piping than connecting individual devices separately. Manifold blocks come in various shapes and sizes, are tailored to specific applications, and can be customized using circuit design software.

Uses of Manifold Blocks

Manifold blocks are utilized in diverse applications, including machine tools, semiconductor manufacturing, chemical supply facilities, N2 purge systems, oxygen concentrators, and respirators/anesthesia machines, depending on their material composition.

1. Iron

Iron manifold blocks are used for lubricating and cutting oils, particularly to divert oil in machine tools.

2. Stainless Steel

Stainless steel manifold blocks are versatile, and used for water, oil, and air. They can be part of water pressure measurement setups by attaching a pressure gauge.

3. Aluminum Alloy

Aluminum alloy blocks are commonly used for air distribution in air nozzles and are prevalent in construction machinery, agricultural machinery, and vehicles.

Principle of Manifold Blocks

Manifold blocks are made from materials like iron, stainless steel, or aluminum alloy, with intricately drilled holes forming a circuit for fluids like water, oil, and air. These blocks feature threaded entrances for piping connections, allowing for a compact arrangement of multiple pipes.

General-purpose manifold blocks often have straight, T-shaped, or L-shaped holes, designed to densely pack circuits for efficient fluid flow and space utilization.

Features of Manifold Blocks

1. Miniaturization

Manifold blocks enable significant downsizing, offering compactness and high flow rates in small spaces. They can reduce volume requirements by up to 90% compared to traditional piping setups.

2. Panel Mounting

Flexible supply and exhaust port placements allow for versatile piping arrangements and panel mounting capabilities.

3. Valve Flexibility

These blocks support easy switching between normally open and normally closed configurations using a universal pressurization method.

4. Connectivity

Flat cables can be used with manifold blocks, offering top or side connector extraction options.

How to Select a Manifold Block

Many factors should be considered when selecting a manifold block.

1. Operating Pressure and Material

If the pressure to be used is relatively low, an aluminum manifold is suitable. Installation of manifold blocks made of steel may be difficult because of they are heaviness in some locations, leading to injury concerns. Aluminum manifolds are about 1/3 the weight of steel manifolds.

2. Maximum Flow Rate and Port Specifications

Pressure loss must not be small even at maximum flow rate. Ports can be O-ring type G thread, seal washer type G thread, or UNF thread. Seal-tape-type taper screws are not often used due to possible contamination problems.

3. Valve Type

Cartridge valves and laminated valves can be used to further reduce weight and size.

Other Information on Manifold Blocks

Circuit Design

Custom circuit designs can be created using specialized software and CAD tools, allowing for tailored flow paths. Precision machining companies can be engaged for high-accuracy flow path creation.