What Is a Thrust Needle Roller Bearing?

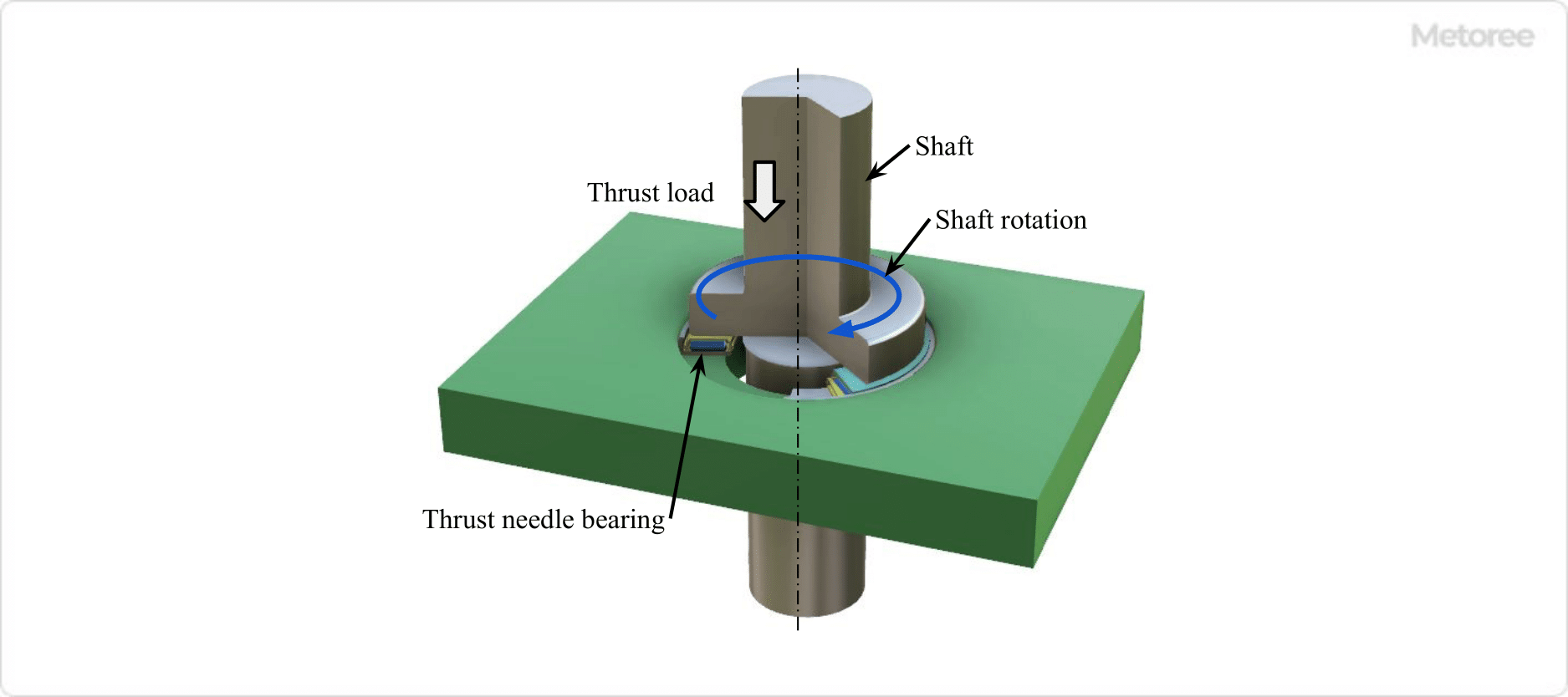

A thrust needle roller bearing consists of needle rollers and retainers, designed to support axial thrust loads (parallel to the shaft’s center).

Figure 1: Thrust Needle Roller Bearing and Thrust Load

Thrust needle roller bearings are the most compact among all thrust bearings. They allow for high-speed rotation without generating significant friction.

A thrust needle roller bearing is a thrust bearing with needle rollers as rolling elements.

Uses of Thrust Needle Roller Bearings

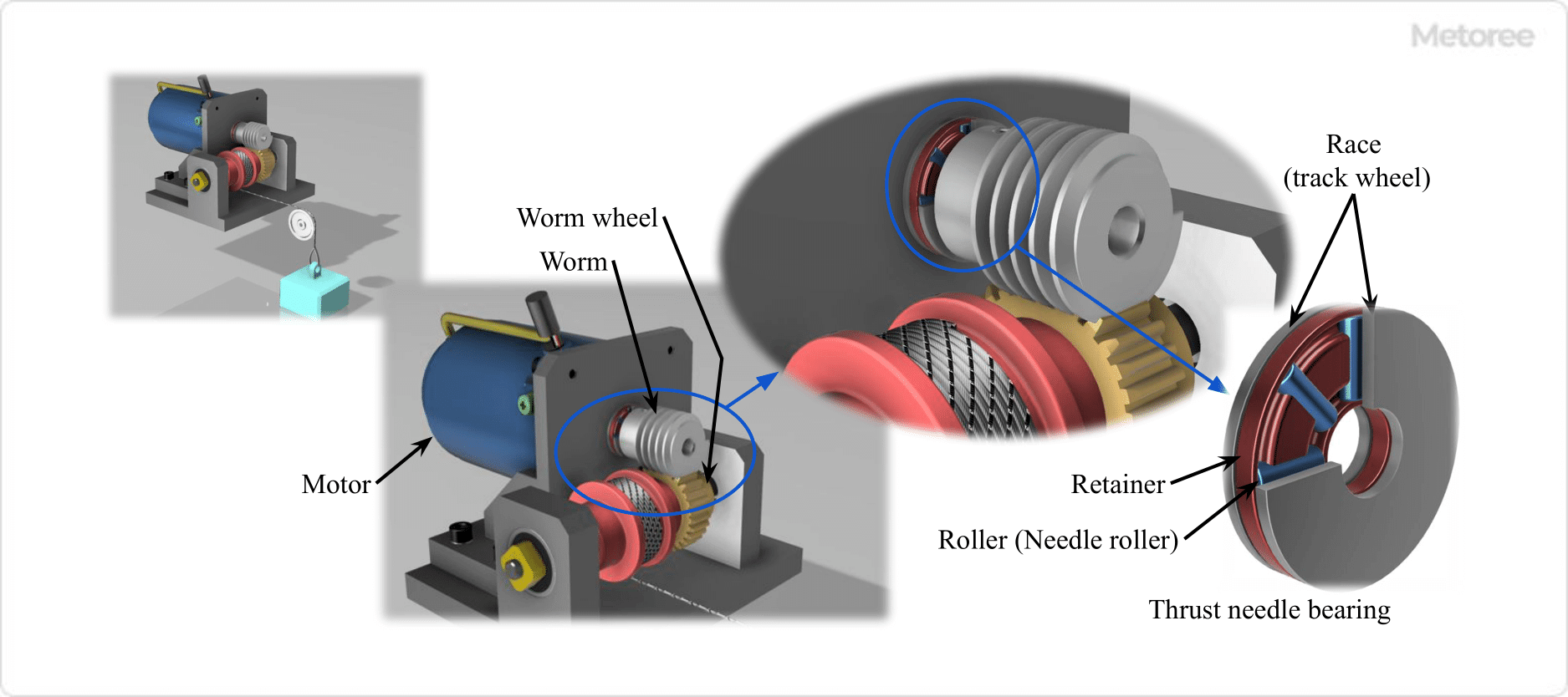

Figure 2: Application of Thrust Needle Roller Bearing

Thrust needle roller bearings are rigid, compact, and capable of handling large loads and high speeds, making them suitable for various applications.

In automobiles, they are used in areas supporting high axial loads, such as engines and differential gears, and as bearings in automatic transmissions. Other applications include machine tools, robots, aircraft, and industrial machinery.

Figure 1 illustrates their use in a winch with a worm gear, where the worm attached to the motor output shaft exerts a thrust load towards the center of the worm shaft. A thrust needle roller bearing is incorporated to prevent the load from affecting the motor output shaft.

Principle of Thrust Needle Roller Bearings

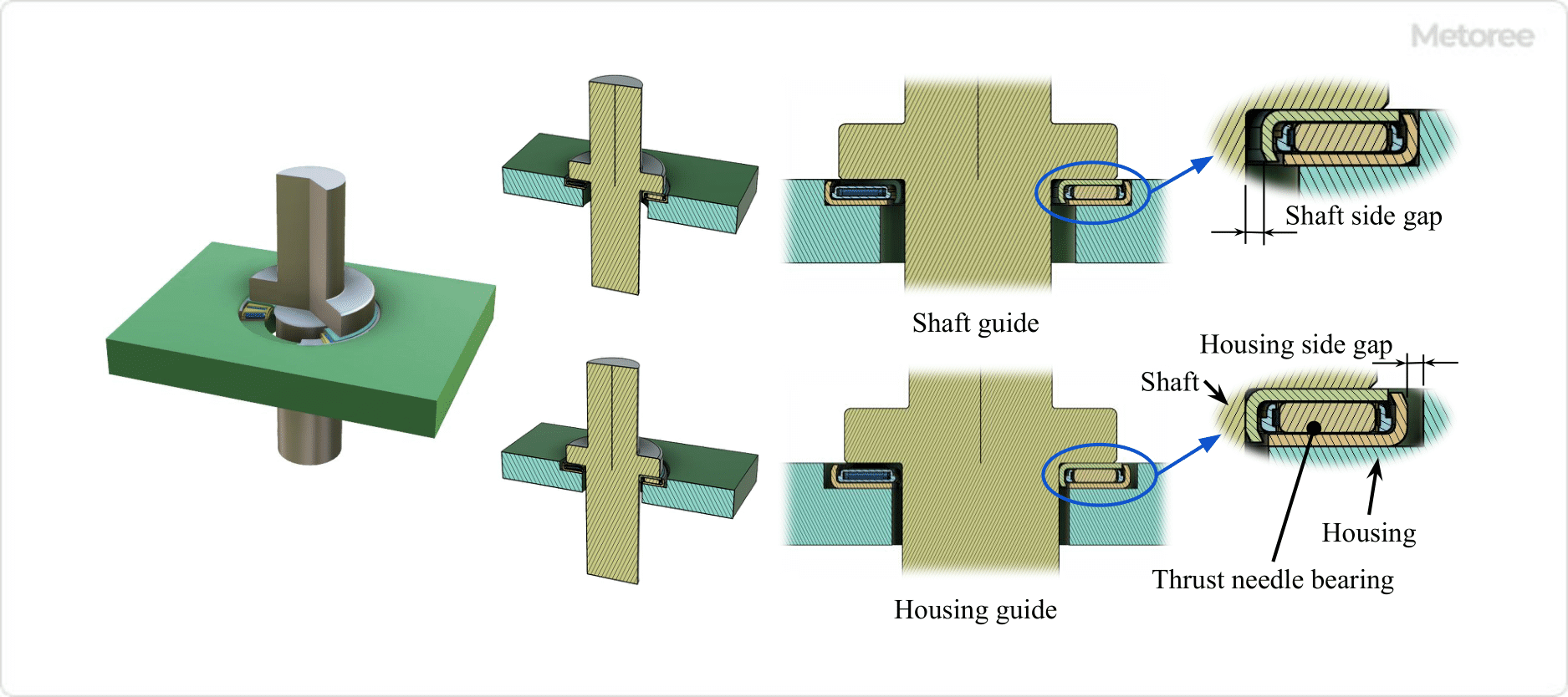

Figure 3: Shaft Guide and Housing Guide

Thrust needle roller bearings feature needle rollers arranged in a circumferential pattern, with retainers maintaining the spacing between rollers and allowing each to rotate independently. This design supports high loads through linear contact, with a small contact area that results in low friction, even at high rotational speeds.

Thrust needle roller bearings can be mounted in two ways:

- Shaft Guided (Bore Guided): Large clearance between the shaft and bearing inner side, with a small clearance between the housing and bearing outer side.

- Housing Guided (Od Guided): Large clearance between the housing and bearing outer side, with a small clearance between the shaft and bearing inner side.

They are primarily used with shaft guideways and are recommended for high-speed rotation applications.

Types of Thrust Needle Roller Bearings

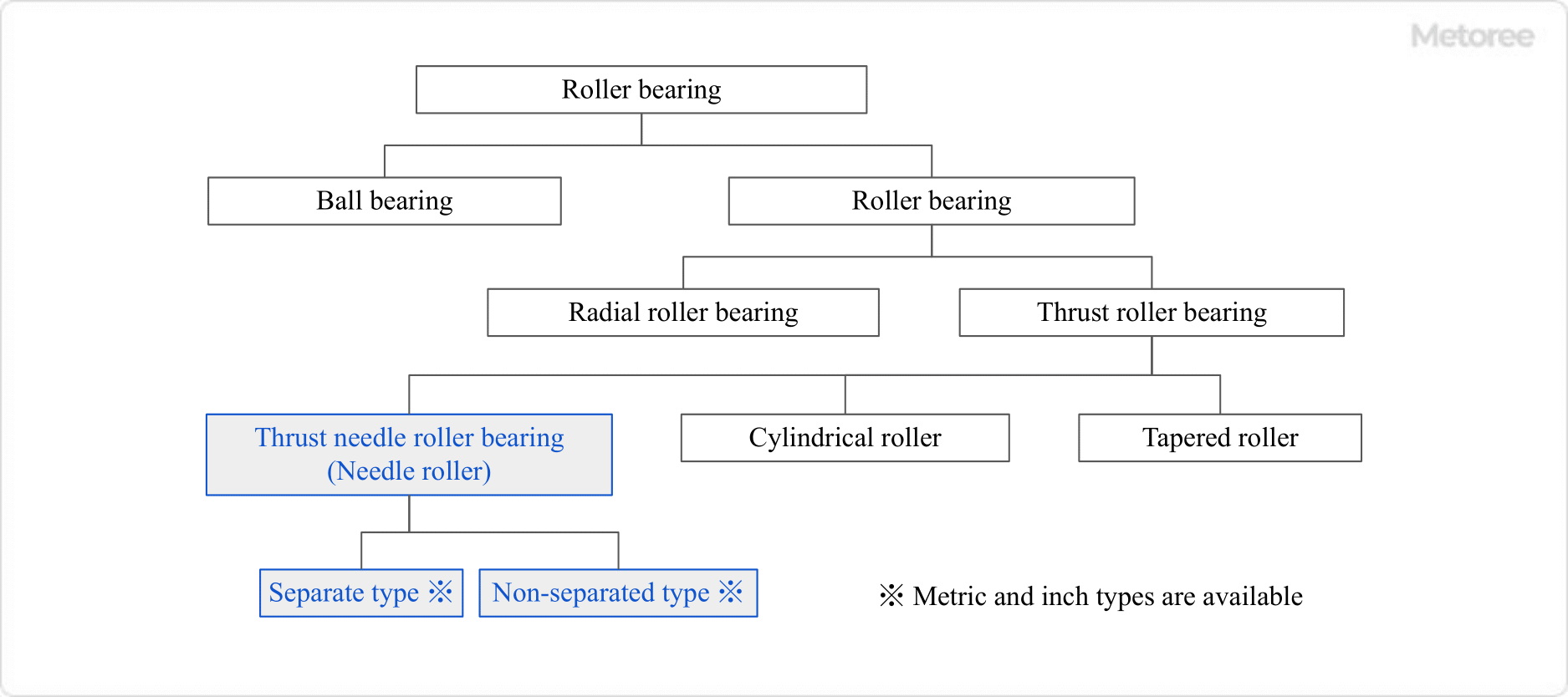

Figure 4: Bearing Type System

Roller bearings are broadly classified into ball bearings and roller bearings, which are further categorized into radial and thrust roller bearings, respectively. Thrust needle roller bearings fall under the thrust roller bearing category.

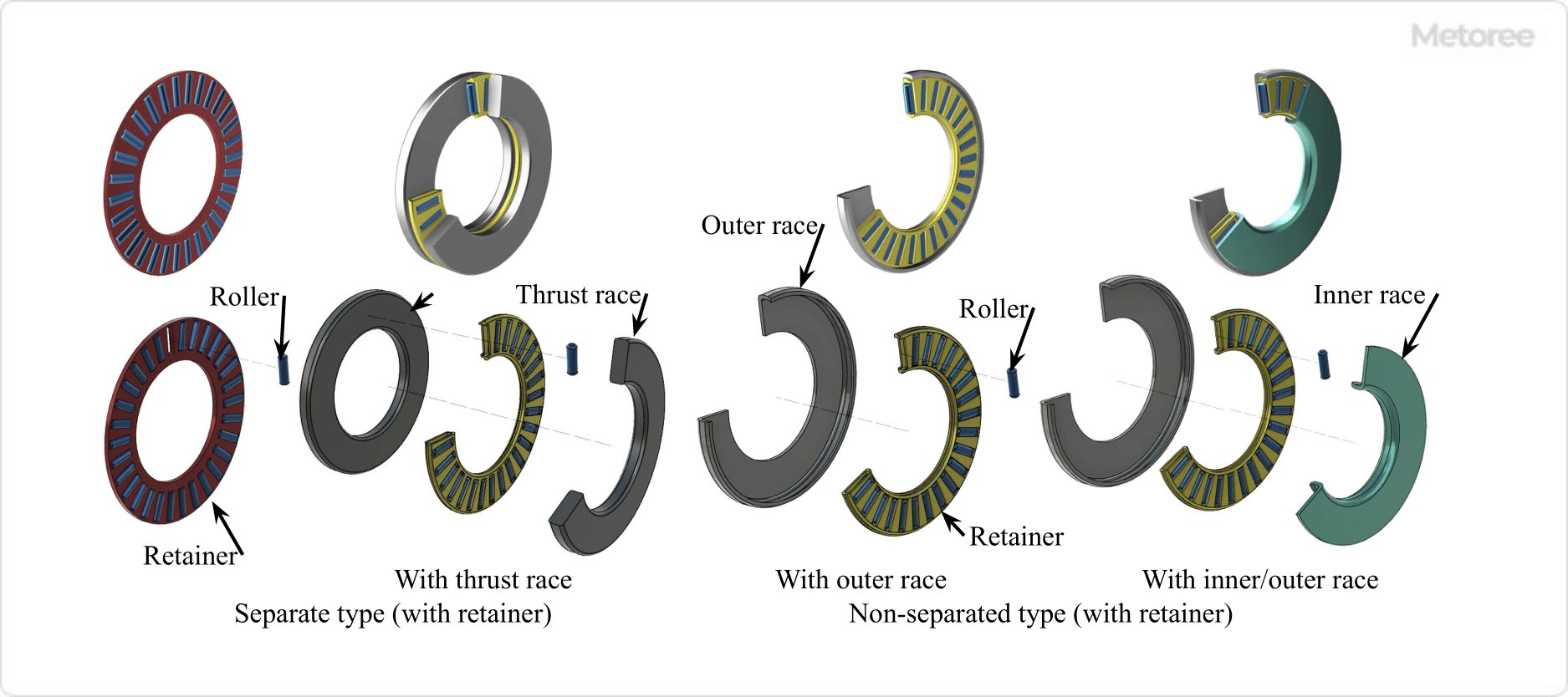

Depending on the roller shape, there are needle rollers, cylindrical rollers, and tapered rollers. Thrust needle roller bearings come in separated and non-separated types, distinguished by whether the needle roller and retainer can be detached from the thrust race or are integral and non-detachable.

Figure 5: Types of Thrust Needle Roller Bearings

Separate types can be used either with the retainer and needle roller between the thrust races or without a thrust race. For bearings without a thrust race, the needle roller contact surfaces must be finely ground and hardened. Thrust races come in two types: shaft guideway and housing guideway.