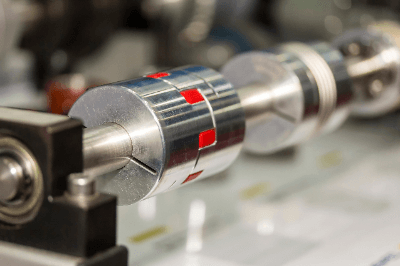

What Is a Jaw Flex Coupling?

Jaw flex couplings belong to the category of flex couplings.

A coupling, or shaft coupling, serves as a mechanical component that links a drive shaft with a driven shaft to transmit power. Flex couplings are designed to absorb misalignments between the drive and driven shafts, thereby mitigating misalignment effects.

In contrast, rigid couplings offer zero backlash and efficient power transmission. Jaw flex couplings excel in vibration and shock absorption due to rotational movements and are straightforward to install and remove.

Uses of Jaw Flex Couplings

Jaw flex couplings are primarily utilized as shaft couplings in machinery prone to significant vibration and shock. Their outstanding vibration and misalignment absorption capabilities make them particularly suited for shaft couplings in induction motors and other applications demanding high-speed rotation and high torque.

Easy to maintain, jaw flex couplings with sleeves allow for disassembly and assembly without the need to move the drive and driven shafts by merely removing the sleeve.

They are also employed as shaft couplings in pumps, compressors, blowers, machine tools, packaging machines, robots, and more.

Principle of Jaw Flex Couplings

Couplings fulfill four crucial functions:

- Power transmission from the drive shaft to the driven shaft.

- Absorption of mounting errors between the drive and driven shafts.

- Vibration absorption of the drive shaft, preventing its propagation to adjacent equipment.

- Heat transmission from the drive shaft to the driven shaft.

Jaw flex couplings are notably efficient in the second and third functions mentioned. They incorporate a sleeve (or spider, or in-shear spider) between the drive and driven shafts to allow for a degree of misalignment (eccentricity, angular misalignment, axial displacement, etc.) and use their flexibility to absorb vibration and shock, ensuring stable rotation. This tolerance to misalignment also reduces the need for high machining precision, thereby lowering production costs and simplifying machine assembly and adjustment.

When utilized in motor couplings, jaw flex couplings partially shield the motors from operational vibrations.

Types of Jaw Flex Couplings

Jaw flex couplings vary in construction, sleeve shape, and material.

1. Classification by Construction

The fundamental structure of a jaw flex coupling includes a hub on the drive shaft, a hub on the driven shaft, and a cushioning material inserted between the hubs to connect the shafts.

The cushioning material comes in three shapes: sleeve type, spider type, and in-shear spider type. The in-shear spider type includes an external retainer for protection.

2. Classification by Material

The materials commonly used in jaw flex couplings are detailed below.

Hub materials are selected based on the operating environment, including considerations for corrosive conditions. Sleeves and spiders, as cushioning materials, vary in characteristics depending on the material and are chosen according to the operating temperature range and shock compatibility.

Nitrile rubber offers excellent impact resistance but is less chemically resistant than urethane, though it has a slightly broader operating temperature range. Copper alloy is preferred for high-torque applications, particularly at low rotational speeds.