What Is a Ball Mill?

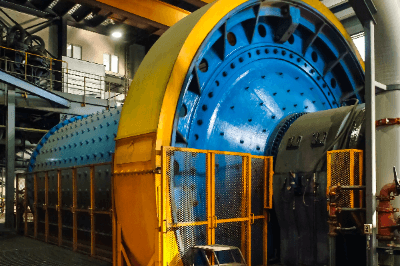

A ball mill is a type of milling equipment that performs milling by rotating balls of alumina or other material in a cylindrical container as the milling medium. In a broad sense, there are the vibration ball mill that vibrates a container, and planetary ball mill that rotates the container, but generally speaking, ball mills that rotate containers are more common.

The grinding balls (20 to 100 mm in diameter) and raw materials are placed in this device, which can rotate horizontally, and the raw materials are finely ground by collision with the grinding balls, impact between the grinding balls and the inner surface, and frictional crushing.

Bead mills are also used to pulverize raw materials. The grinding power of a ball mill is determined by the free fall of the grinding balls. In contrast, in a bead mill, strong impact force is applied by centrifugal force by a stirring device. Another feature of bead mills is that the bead diameter is smaller than that of a ball mill, at 2 mm or less. Due to the difference in milling energy and other characteristics, these types of equipment are used differently in the field.

Uses of Ball Mills

Ball mills are used in a wide variety of fields, such as ore, coal, cement, pharmaceuticals, ceramics, and metals, because of their simple structure and ease of scale-up. Some examples are listed below.

- Titanium dioxide (applications: pigments, colorants, photocatalysts, offset printing, cosmetics)

- Carbon black rubber (applications: product reinforcement, paints, additives for magnetic recording media, battery materials)

- Barium titanate (Applications: ceramic capacitors, laminated capacitors, and other electronic components)

- Alumina (Applications: ceramics and abrasives)

- Resin (Applications: some battery parts and use in general-purpose plastics)

Principle of Ball Mills

The optimum rotation speed N of ball mills depends on the size of the grinding media, grinding method (dry or wet), presence of lifters, and size of the mill. In general, ball mill specifications are expressed as the ratio of the critical speed Nc to the optimum speed N (N / Nc). The “critical rotation speed Nc” shown here is the minimum speed at which particles remain crimped to the far east inner wall due to centrifugal force. When calculating the rotational speed when the milling balls are 30 mm in diameter, it is common to obtain values of 75% for the dry type and 65% for the wet type.

The ratio of powder, balls, and space in the vessel also affects the milling process. Generally, each should be about 1/3 of the volume, but in practice, conditions should be changed depending on the sample and purpose (processing time and batch volume).

In dry milling, the raw material and balls are placed in the mill. The advantage of this simple structure is that impurities are unlikely to be mixed in. In wet milling, water or an organic solvent is added in addition to the raw materials and grinding balls. This method is suitable for blending and mixing raw materials. An air purge mechanism is standard to improve the discharge efficiency of the milled products. Special containers are sometimes used for ball mills. This is used for the grinding of materials that are explosive or oxidizable during the grinding process.

How to Select Ball Mills

There are two main types of ball mill containers: ceramic and metal. Metal is used for large production applications, but if there are concerns about metal contamination or corrosion, the inner walls must be lined with rubber or urethane. This increases the cost and may be difficult to manufacture depending on the size. Balls are made of the same material as the container. The larger the density of the material, the stronger the crushing force, and the smaller the ball diameter, the more contact points there are, thus increasing the crushing capacity. However, some materials are more prone to wear than others, so care must be taken in selecting the right material.