What Is a Float Ball Valve?

A float ball valve is a device used to regulate the water level in a container using a float mechanism.

Commonly installed in tanks and vessels that store liquids, float ball valves control the inflow and outflow of fluids in response to changes in water level. They are known for their simple operation and the ease of controlling the water level. The valve operates automatically based on the float’s position, eliminating the need for manual operation or adjustments.

Due to their few mechanical parts and minimal maintenance requirements, float ball valves are reliable over long periods. They are also cost-effective and energy-efficient, as they do not use electricity for water level adjustment. This contributes to water and energy savings by optimizing fluid supply and discharge.

Applications of Float Ball Valves

Float ball valves have diverse applications, ranging from industrial uses to household items. In toilet water supply systems, for example, the float ball valve opens to refill the tank when the water level drops and closes when the water level reaches a set point.

In industrial settings, such as cooling towers in power plants, float ball valves play a crucial role. They ensure a consistent supply of cooling water, which evaporates and decreases over time, maintaining the required water level.

These valves are also integral to agricultural irrigation systems, where they regulate water supply to fields. Maintaining a consistent water level ensures optimal watering of crops.

Principle of Float Ball Valves

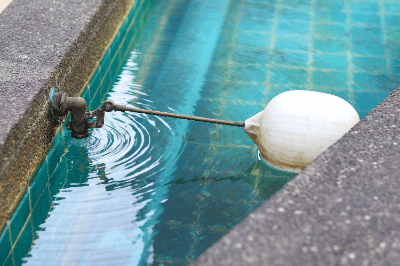

The float ball valve operates on the interplay between buoyancy and valve control. The valve features a float, typically spherical or disk-shaped and made from lightweight materials, that rises and falls with the liquid level.

This movement controls a valve attached to the float. The valve opens to allow fluid into the tank when the float drops and closes to stop the influx as the water level rises and the float ascends.

How to Select a Float Ball Valve

When choosing a float ball valve, consider the following factors:

1. Material

Select a material that suits the fluid and environment where the float ball valve will be used. Common materials include corrosion-resistant options like stainless steel and brass, with plastic being a viable choice in certain conditions. Consider durability and chemical compatibility when selecting the material.

2. Valve Diameter

The valve diameter directly affects the volume of fluid the float ball valve can handle. Choose a diameter based on the fluid volume requirements, keeping in mind that larger diameters can handle more fluid but may be bulkier and more expensive.

3. Structure

Float ball valves come in single and duplex types. Single-type valves have one arm that responds to water level changes, whereas duplex types use multiple arms for more precise control. The choice between single and duplex should be based on the required accuracy and operating environment.

4. Installation Method

The installation method for float ball valves varies depending on the system. Common methods include flange mounting and screw mounting. Select the method that best fits the system specifications and available space.